Table of Contents

Types of Micron Filter Mesh: Understanding the Options

Micron filter mesh is an essential component in various industries, serving as a critical barrier that ensures the purity and quality of fluids and gases. Understanding the different types of micron filter mesh available is crucial for selecting the right option for specific applications. The diversity in micron filter mesh types caters to a wide range of needs, from industrial processes to consumer products, each designed to meet unique filtration requirements.

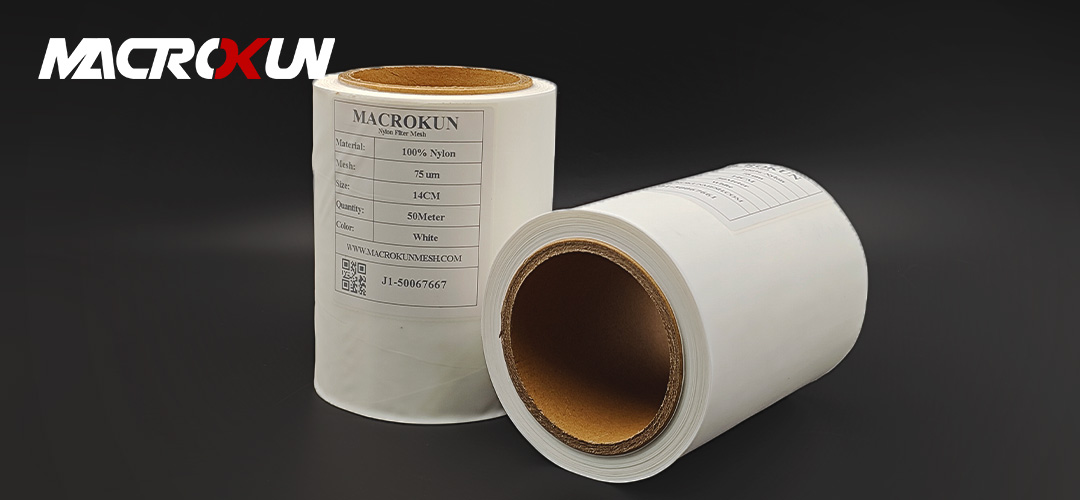

One of the most common types of micron filter mesh is the woven mesh, which is made from interlaced fibers. This type is particularly effective for applications requiring high flow rates and durability. Woven mesh is available in various materials, including stainless steel, nylon, and polyester, allowing for versatility in different environments. The choice of material often depends on the chemical compatibility and temperature resistance required for the application. For instance, stainless steel woven mesh is ideal for high-temperature and corrosive environments, while nylon mesh is suitable for less demanding conditions.

Another significant category is the non-woven filter mesh, which is created by bonding fibers together rather than weaving them. This type of mesh offers a higher dirt-holding capacity and is often used in applications where fine filtration is necessary. Non-woven meshes are commonly found in air and liquid filtration systems, where they effectively capture smaller particles that woven meshes might miss. The structure of non-woven mesh allows for a more uniform filtration process, making it a preferred choice in industries such as pharmaceuticals and food processing, where purity is paramount.

In addition to woven and non-woven options, there are also specialized micron filter meshes designed for specific applications. For example, pleated filter mesh increases the surface area available for filtration, enhancing the efficiency of the filtration process. This design is particularly beneficial in applications where space is limited, as it allows for a more compact filter without sacrificing performance. Pleated filters are widely used in HVAC systems and water treatment facilities, where maximizing filtration efficiency is crucial.

Furthermore, the choice of micron rating is a critical factor in selecting the appropriate filter mesh. Micron ratings indicate the size of particles that the mesh can effectively filter out, with lower ratings providing finer filtration. For instance, a 1-micron filter mesh is capable of capturing particles as small as one micron, making it suitable for applications requiring high levels of purity. Conversely, a 100-micron filter mesh is more appropriate for applications where larger particles are present, such as in industrial processes involving slurries or coarse liquids.

The advancements in technology have also led to the development of innovative filter mesh materials, such as electrospun nanofibers. These materials offer exceptional filtration capabilities, capturing particles at the nanoscale while maintaining high flow rates. Such advancements are particularly relevant in industries like biotechnology and nanotechnology, where precision filtration is essential.

In conclusion, the wide range of micron filter mesh types available today provides solutions for various filtration needs across multiple industries. From woven and non-woven meshes to specialized pleated designs and advanced nanofiber materials, each option offers distinct advantages tailored to specific applications. Understanding these options allows businesses to make informed decisions, ensuring optimal performance and compliance with industry standards. As the demand for high-quality filtration continues to grow, the importance of selecting the right micron filter mesh cannot be overstated, as it directly impacts the efficiency and effectiveness of filtration processes.

Applications of Micron Filter Mesh in Various Industries

Micron filter mesh is a crucial component in many industries, providing a means to separate particles of different sizes and ensure the purity of liquids and gases. With a wide range of micron filter mesh types available, there is a solution for every application, no matter how specific or demanding.

In the food and beverage industry, micron filter mesh is used to remove impurities and contaminants from liquids such as juices, wines, and dairy products. By selecting the appropriate micron size, manufacturers can achieve the desired level of filtration without compromising the quality of the final product. For example, a finer micron filter mesh may be used to remove bacteria and yeast from wine, while a coarser mesh may be sufficient for filtering fruit juices.

In the pharmaceutical industry, micron filter mesh plays a critical role in ensuring the safety and efficacy of medications. By using micron filter mesh to remove particles and impurities from drug formulations, manufacturers can guarantee that their products meet the highest standards of purity and quality. Whether filtering liquid medications or powders, there is a micron filter mesh solution to suit every need.

In the automotive industry, micron filter mesh is used in a variety of applications, from filtering engine oil to purifying fuel. By selecting the appropriate micron size and material, manufacturers can protect critical components from damage and ensure the optimal performance of vehicles. For example, a stainless steel micron filter mesh may be used to remove contaminants from engine oil, while a nylon mesh may be suitable for filtering fuel.

In the water treatment industry, micron filter mesh is essential for removing particles and impurities from drinking water and wastewater. By using micron filter mesh to trap sediment, bacteria, and other contaminants, water treatment plants can produce clean and safe water for consumption and disposal. Whether filtering large volumes of water or treating small batches, there is a micron filter mesh solution to meet the needs of every application.

In the electronics industry, micron filter mesh is used to protect sensitive components from dust, dirt, and other contaminants. By using micron filter mesh to create barriers and enclosures, manufacturers can ensure the reliability and longevity of electronic devices. Whether filtering air intake vents or enclosing circuit boards, there is a micron filter mesh solution to safeguard electronics from harm.

In conclusion, the wide range of micron filter mesh types available makes it possible to find a solution for every application in various industries. Whether filtering liquids, gases, or solids, there is a micron filter mesh that can meet the specific requirements of each industry. By selecting the appropriate micron size, material, and configuration, manufacturers can achieve the desired level of filtration and ensure the purity and quality of their products.

Choosing the Right Micron Filter Mesh for Your Needs

When it comes to choosing the right micron filter mesh for your specific needs, it’s important to understand the wide range of options available on the market. Micron filter mesh is used in a variety of industries, including pharmaceutical, food and beverage, chemical, and water treatment. Each industry has its own unique requirements when it comes to filtration, which is why there are so many different types of micron filter mesh to choose from.

One of the most important factors to consider when selecting a micron filter mesh is the size of the particles you need to filter out. Micron filter mesh is available in a wide range of sizes, from as small as 5 microns to as large as 500 microns. The smaller the micron size, the finer the particles that can be filtered out. For example, a 5-micron filter mesh is ideal for filtering out very small particles, while a 500-micron filter mesh is better suited for larger particles.

Another important factor to consider when choosing a micron filter mesh is the material it is made from. Micron filter mesh can be made from a variety of materials, including stainless steel, nylon, and polyester. Each material has its own unique properties that make it suitable for different applications. For example, stainless steel filter mesh is highly durable and resistant to corrosion, making it ideal for use in harsh environments. nylon filter mesh, on the other hand, is lightweight and flexible, making it easy to work with.

In addition to size and material, the weave of the micron filter mesh is also an important consideration. Micron filter mesh can be woven in a variety of patterns, including plain weave, twill weave, and Dutch weave. Each weave pattern has its own unique characteristics that make it suitable for different applications. For example, a plain weave filter mesh is ideal for general filtration applications, while a Dutch weave filter mesh is better suited for applications that require a high level of filtration efficiency.

When choosing a micron filter mesh, it’s also important to consider the flow rate of the filtration system. The flow rate is the rate at which fluid can pass through the filter mesh, and it is typically measured in gallons per minute (GPM). A higher flow rate is desirable for applications that require a large volume of fluid to be filtered quickly, while a lower flow rate is suitable for applications that require a more thorough filtration process.

In conclusion, choosing the right micron filter mesh for your specific needs requires careful consideration of a variety of factors, including particle size, material, weave pattern, and flow rate. By understanding the wide range of options available on the market and selecting the best filter mesh for your application, you can ensure that your filtration system operates efficiently and effectively.