Table of Contents

Different Types of Micron Filter Mesh

Micron filter mesh is an essential component in many industries, including pharmaceuticals, food and beverage, and water treatment. It plays a crucial role in separating solids from liquids, ensuring that only the desired particles pass through. However, not all micron filter meshes are created equal. There are different types available, each with its unique characteristics and applications. Understanding the various kinds of micron filter mesh is crucial in finding the right type for your specific needs.

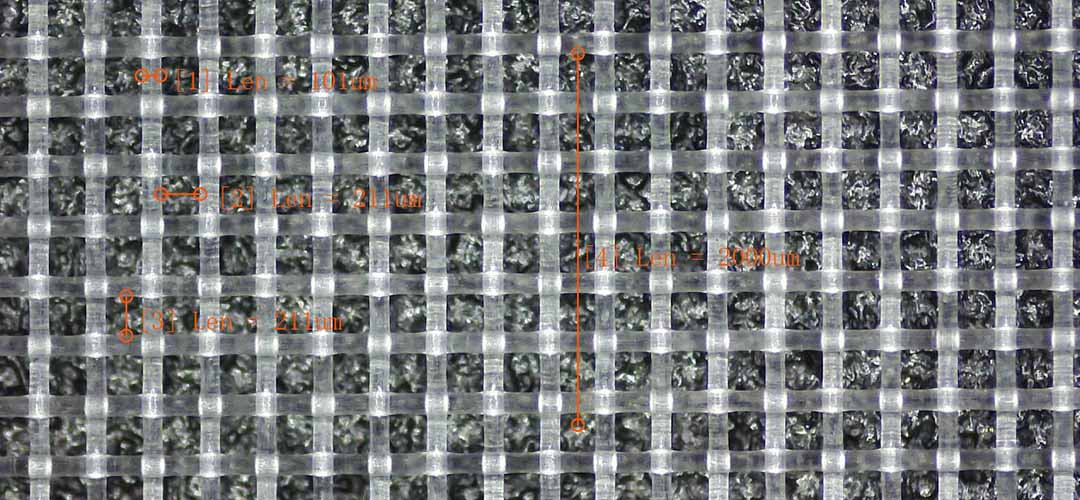

One of the most common types of micron filter mesh is the woven wire mesh. This type of mesh is made by weaving metal wires together to create a grid pattern. Woven wire mesh is known for its durability and strength, making it ideal for applications where high pressure and temperature are involved. It is also highly versatile, with different weave patterns available to suit different filtration requirements.

Another type of micron filter mesh is the sintered mesh. Sintered mesh is made by sintering multiple layers of woven wire mesh together, creating a porous structure that allows for precise filtration. This type of mesh is known for its high filtration efficiency and uniform porosity, making it ideal for applications where fine filtration is required. Sintered mesh is also resistant to corrosion and can withstand high temperatures, making it suitable for harsh environments.

In addition to woven wire mesh and sintered mesh, there are also other types of micron filter mesh available, such as perforated metal mesh and expanded metal mesh. Perforated metal mesh is made by punching holes into metal sheets, creating a pattern that allows for precise filtration. Expanded metal mesh, on the other hand, is made by cutting and stretching metal sheets, creating a mesh with diamond-shaped openings. Both types of mesh are suitable for applications where high flow rates are required.

When choosing the right type of micron filter mesh for your needs, it is essential to consider factors such as the particle size you need to filter, the flow rate required, and the operating conditions of your application. For example, if you need to filter fine particles, a sintered mesh may be the best option. If you require high flow rates, a perforated metal mesh or expanded metal mesh may be more suitable.

It is also essential to consider the material of the mesh. Different materials offer different properties, such as corrosion resistance, temperature resistance, and chemical compatibility. Stainless steel is a popular choice for micron filter mesh due to its durability and resistance to corrosion. However, other materials such as brass, copper, and titanium are also available, each with its unique characteristics.

In conclusion, understanding the different types of micron filter mesh is crucial in finding the right type for your specific needs. Whether you require fine filtration, high flow rates, or resistance to harsh environments, there is a type of micron filter mesh that will meet your requirements. By considering factors such as particle size, flow rate, operating conditions, and material, you can choose the best type of micron filter mesh for your application.

How to Choose the Right Micron Filter Mesh for Your Application

When it comes to choosing the right micron filter mesh for your application, it’s important to understand the different kinds available and how they can best suit your needs. Micron filter mesh is a versatile tool used in a variety of industries, including food and beverage, pharmaceuticals, chemicals, and more. By selecting the right type of micron filter mesh, you can ensure that your filtration process is efficient and effective.

One of the first things to consider when choosing a micron filter mesh is the material it is made from. Micron filter mesh can be made from a variety of materials, including stainless steel, nylon, and polyester. Each material has its own unique properties that make it suitable for different applications. Stainless steel mesh, for example, is durable and resistant to corrosion, making it ideal for use in harsh environments. nylon mesh, on the other hand, is lightweight and flexible, making it a good choice for applications where flexibility is important.

Another important factor to consider when choosing a micron filter mesh is the size of the openings in the mesh. The size of the openings, or the micron rating, determines the size of particles that can pass through the mesh. Micron filter mesh is available in a wide range of micron ratings, from as low as 1 micron to as high as 500 microns or more. The right micron rating for your application will depend on the size of the particles you need to filter out. For example, if you are filtering out large particles, you may need a mesh with a higher micron rating, while if you are filtering out smaller particles, you may need a mesh with a lower micron rating.

In addition to material and micron rating, it’s also important to consider the weave of the mesh when choosing a micron filter mesh. The weave of the mesh refers to the pattern in which the threads are woven together. There are several different types of weaves available, including plain weave, twill weave, and Dutch weave. Each type of weave has its own unique properties that make it suitable for different applications. Plain weave, for example, is the most common type of weave and is suitable for general filtration applications. Twill weave, on the other hand, is more tightly woven and is ideal for applications where a higher level of filtration is required.

When choosing a micron filter mesh, it’s important to consider all of these factors to ensure that you select the right type for your needs. By understanding the different kinds of micron filter mesh available and how they can best suit your application, you can ensure that your filtration process is efficient and effective. Whether you are filtering out large particles or small particles, working in a harsh environment or a more controlled setting, there is a micron filter mesh that is right for you. Take the time to research and consider your options to find the perfect micron filter mesh for your application.

Understanding the Importance of Micron Ratings in Filter Meshes

Micron filter mesh is an essential component in many industries, including pharmaceuticals, food and beverage, and water treatment. Understanding the importance of micron ratings in filter meshes is crucial for selecting the right type for your specific needs.

Micron ratings refer to the size of the openings in the filter mesh, which determine the size of particles that can pass through. The lower the micron rating, the smaller the particles that can be filtered out. For example, a filter with a micron rating of 5 will capture particles as small as 5 microns in size.

In industries where the purity of the final product is critical, such as pharmaceuticals and food and beverage, selecting the right micron rating is essential. A filter mesh with too large of a micron rating may allow contaminants to pass through, compromising the quality of the product. On the other hand, a filter mesh with too small of a micron rating may clog easily, reducing efficiency and increasing maintenance costs.

When choosing a micron filter mesh, it is important to consider the specific requirements of your application. Factors such as the type of particles being filtered, the flow rate, and the desired level of filtration will all impact the appropriate micron rating. Consulting with a filtration expert can help ensure that you select the right type of filter mesh for your needs.

There are several different types of micron filter meshes available, each with its own unique characteristics and applications. Some common types include nylon mesh, polyester mesh, and stainless steel mesh. Nylon mesh is often used in applications where chemical resistance is important, while polyester mesh is preferred for its durability and resistance to abrasion. Stainless steel mesh is ideal for high-temperature applications and where strength and durability are paramount.

In addition to micron ratings, it is also important to consider the weave pattern of the filter mesh. The weave pattern refers to the way in which the threads are interlaced to create the mesh. Common weave patterns include plain weave, twill weave, and Dutch weave. Each weave pattern offers different levels of filtration efficiency and flow rates, so it is important to select the right pattern for your specific application.

Understanding the importance of micron ratings in filter meshes is essential for selecting the right type for your needs. By considering factors such as the type of particles being filtered, flow rate, and desired level of filtration, you can ensure that you choose a filter mesh that meets your requirements. Consulting with a filtration expert can help guide you through the selection process and ensure that you select the best filter mesh for your application.