Table of Contents

Benefits of Using a 200 mesh filter in microns for Filtration

When it comes to filtration, choosing the right filter is crucial to ensure the efficiency and effectiveness of the process. One commonly used filter is the 200 mesh filter in microns, which offers a range of benefits for various filtration needs. Understanding the advantages of using a 200 mesh filter in microns can help you make informed decisions when selecting a filter for your specific application.

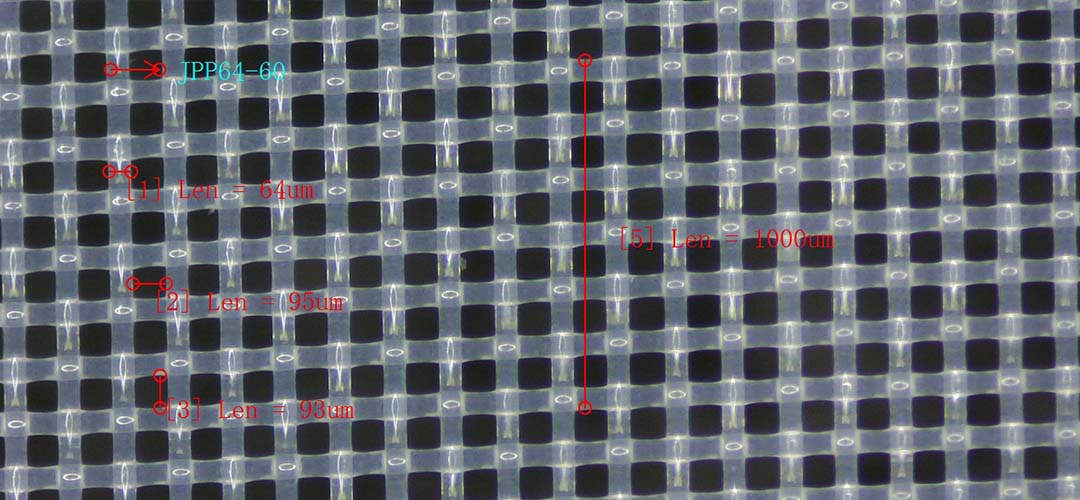

One of the key benefits of using a 200 mesh filter in microns is its ability to provide fine filtration. The term “200 mesh” refers to the number of openings per inch in the filter screen, with each opening measuring 74 microns in size. This fine mesh size allows the filter to capture small particles and contaminants, making it ideal for applications that require high levels of filtration precision.

In addition to its fine filtration capabilities, a 200 mesh filter in microns also offers a high flow rate. The small openings in the filter screen allow for efficient fluid flow while still effectively capturing particles. This high flow rate is essential for applications that require fast filtration processes or that involve high volumes of fluid.

Another advantage of using a 200 mesh filter in microns is its versatility. These filters can be used in a wide range of applications, including water filtration, oil filtration, chemical filtration, and more. Whether you are filtering liquids or gases, a 200 mesh filter in microns can provide the level of filtration precision needed for your specific application.

Furthermore, a 200 mesh filter in microns is durable and long-lasting. Made from high-quality materials such as stainless steel or brass, these filters are designed to withstand harsh operating conditions and frequent use. This durability ensures that the filter will continue to perform effectively over time, reducing the need for frequent replacements and maintenance.

Using a 200 mesh filter in microns can also help improve the overall quality of your filtration process. By capturing small particles and contaminants, these filters can help prevent clogs, blockages, and other issues that can affect the efficiency of your filtration system. This can lead to cleaner, purer fluids and gases, as well as improved product quality and consistency.

In conclusion, the benefits of using a 200 mesh filter in microns for filtration are numerous. From its fine filtration capabilities and high flow rate to its versatility, durability, and ability to improve filtration quality, a 200 mesh filter in microns is an excellent choice for a wide range of applications. Whether you are filtering water, oil, chemicals, or other substances, a 200 mesh filter in microns can provide the level of filtration precision and efficiency needed to meet your specific requirements. Consider incorporating a 200 mesh filter in microns into your filtration system to experience these benefits firsthand.

How to Choose the Right 200 Mesh Filter for Your Filtration Needs

When it comes to choosing the right filter for your filtration needs, understanding the 200 mesh filter in microns is crucial. Mesh size is a measurement of the number of openings per inch in a screen or filter. In the case of a 200 mesh filter, there are 200 openings per inch. This means that the filter can capture particles that are smaller than 74 microns in size.

The size of particles that a filter can capture is important because it determines the level of filtration that the filter can provide. In general, the smaller the mesh size, the finer the filtration. A 200 mesh filter is considered to be a fine filter, suitable for capturing small particles that may be present in liquids or gases.

When choosing a 200 mesh filter for your filtration needs, there are a few factors to consider. First, you need to determine the size of the particles that you need to filter out. If you are dealing with very small particles, a 200 mesh filter may be the right choice for you. However, if you are dealing with larger particles, you may need a coarser filter.

Another factor to consider when choosing a 200 mesh filter is the material of the filter. Filters can be made from a variety of materials, including stainless steel, nylon, and polyester. The material of the filter will affect its durability and effectiveness. Stainless steel filters are often preferred for their strength and resistance to corrosion, while nylon filters are lightweight and easy to clean.

In addition to the mesh size and material, you should also consider the flow rate of the filter. The flow rate is the amount of liquid or gas that can pass through the filter in a given amount of time. A 200 mesh filter with a high flow rate will be able to filter larger volumes of liquid or gas more quickly.

When choosing a 200 mesh filter, it is important to consider the specific requirements of your filtration system. If you are filtering a liquid, you may need a filter that is compatible with the type of liquid you are filtering. If you are filtering a gas, you may need a filter that can withstand high temperatures or pressures.

Overall, understanding the 200 mesh filter in microns is essential for choosing the right filter for your filtration needs. By considering factors such as mesh size, material, flow rate, and compatibility with your filtration system, you can ensure that you select a filter that will provide the level of filtration that you require. Whether you are filtering liquids or gases, a 200 mesh filter can help you achieve the level of filtration that you need for your specific application.

Common Mistakes to Avoid When Using a 200 Mesh Filter in Microns

When it comes to filtration, using the right mesh size is crucial to achieving the desired level of filtration efficiency. One common mesh size that is widely used in various industries is the 200 mesh filter in microns. Understanding how this filter works and avoiding common mistakes when using it can help you optimize your filtration process and achieve the best results.

The 200 mesh filter refers to a screen with 200 openings per inch. Each opening is equivalent to a certain size in microns, which is a unit of measurement used to describe the size of particles. In the case of a 200 mesh filter, each opening is approximately 74 microns in size. This means that any particle larger than 74 microns will be trapped by the filter, while smaller particles will pass through.

One common mistake that people make when using a 200 mesh filter is assuming that it can capture all particles larger than 74 microns. While the filter is designed to trap particles of this size, it is important to consider factors such as the shape and density of the particles. Irregularly shaped particles or particles with a lower density may be able to pass through the filter, even if they are larger than 74 microns. To ensure effective filtration, it is important to consider the specific characteristics of the particles you are trying to remove and choose the appropriate filter size accordingly.

Another mistake to avoid when using a 200 mesh filter is failing to properly clean and maintain the filter. Over time, particles can accumulate on the surface of the filter, reducing its effectiveness and potentially causing clogs. Regular cleaning and maintenance are essential to ensure that the filter continues to perform optimally. Depending on the type of particles being filtered, you may need to clean the filter more frequently to prevent buildup and maintain efficient filtration.

It is also important to consider the flow rate when using a 200 mesh filter. A higher flow rate can put additional strain on the filter and reduce its effectiveness. It is important to strike a balance between the desired flow rate and the filtration efficiency of the filter. If the flow rate is too high, particles may not have enough contact time with the filter to be effectively trapped. On the other hand, a flow rate that is too low may result in inefficient filtration and longer processing times. Finding the optimal flow rate for your specific filtration needs is essential to achieving the best results.

In conclusion, understanding how a 200 mesh filter works and avoiding common mistakes when using it can help you optimize your filtration process and achieve the desired level of filtration efficiency. By considering factors such as particle size, shape, density, and flow rate, you can ensure that your filter performs optimally and delivers the best results. Regular cleaning and maintenance are also essential to prolong the life of the filter and maintain its effectiveness. By following these guidelines, you can make the most of your 200 mesh filter and achieve superior filtration results in your industry.