Table of Contents

Benefits of Using Ultra-Reliable 10 micron stainless steel filter mesh

When it comes to precision work, having the right tools and equipment is essential. One such tool that is crucial for many industries is the ultra-reliable 10 micron stainless steel filter mesh. This type of filter mesh is known for its durability, strength, and ability to provide precise filtration for a wide range of applications.

One of the key benefits of using a 10 micron stainless steel filter mesh is its high level of reliability. This type of filter mesh is designed to withstand high temperatures, corrosive chemicals, and heavy loads without losing its effectiveness. This means that you can rely on it to provide consistent filtration performance, even in the most demanding conditions.

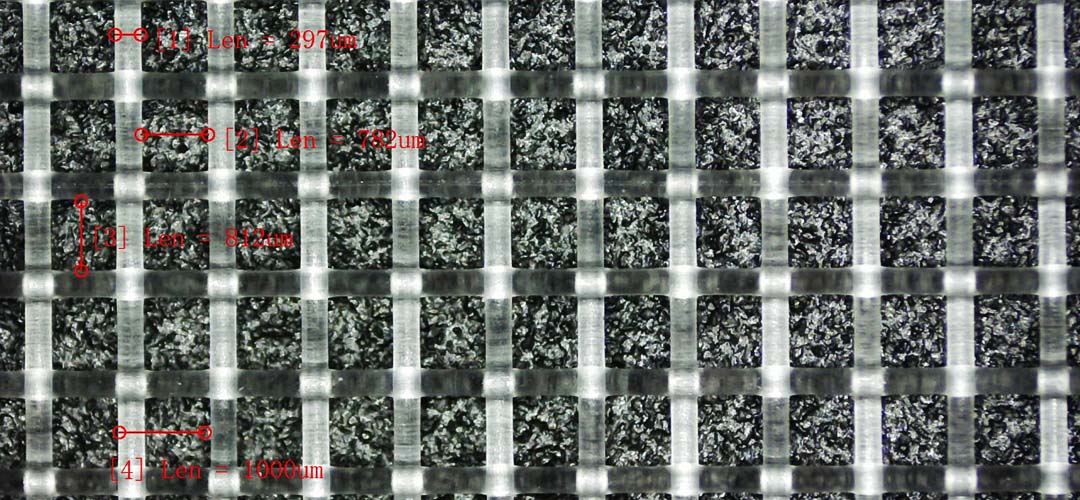

In addition to its reliability, a 10 micron stainless steel filter mesh also offers exceptional precision. The 10 micron size refers to the size of the openings in the mesh, which are incredibly small. This allows the filter mesh to capture even the tiniest particles, ensuring that your filtration process is thorough and efficient.

Another benefit of using a 10 micron stainless steel filter mesh is its versatility. This type of filter mesh can be used in a wide range of applications, including oil and gas filtration, water treatment, food and beverage processing, and pharmaceutical manufacturing. Its ability to handle different types of fluids and particles makes it a valuable tool for many industries.

Furthermore, a 10 micron stainless steel filter mesh is easy to clean and maintain. Unlike other types of filter media that need to be replaced frequently, stainless steel mesh can be cleaned and reused multiple times without losing its effectiveness. This not only saves you money on replacement costs but also reduces downtime and increases productivity.

In conclusion, the ultra-reliable 10 micron stainless steel filter mesh is a valuable tool for precision work in a variety of industries. Its high level of reliability, precision, versatility, and ease of maintenance make it an essential component for any filtration system. Whether you are filtering oil, water, or chemicals, a 10 micron stainless steel filter mesh can provide the consistent and efficient filtration performance you need.

Applications of Precision Work with 10 Micron Stainless Steel Filter Mesh

When it comes to precision work, having the right tools and materials is essential to achieving the desired results. One such material that is crucial for precision work is the 10 micron stainless steel filter mesh. This ultra-reliable mesh is designed to provide exceptional filtration capabilities, making it ideal for a wide range of applications where precision is key.

One of the primary applications of the 10 micron stainless steel filter mesh is in the field of industrial filtration. This mesh is capable of capturing particles as small as 10 microns in size, making it highly effective at removing impurities from liquids and gases. This level of precision is essential in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest contaminants can have a significant impact on product quality.

In addition to industrial filtration, the 10 micron stainless steel filter mesh is also commonly used in laboratory settings. Laboratories require precise filtration to ensure accurate results in experiments and testing. The ultra-fine mesh of the 10 micron stainless steel filter provides the level of filtration needed to achieve reliable and consistent results in a laboratory setting.

Another important application of the 10 micron stainless steel filter mesh is in the automotive industry. This mesh is often used in fuel and oil filtration systems to remove contaminants that can cause damage to engines and other components. The high level of precision offered by the 10 micron stainless steel filter ensures that only clean fluids are allowed to pass through, helping to prolong the life of automotive equipment.

The aerospace industry is another sector that benefits from the use of 10 micron stainless steel filter mesh. In aerospace applications, precision is paramount, and any impurities in fluids or gases can have serious consequences. The 10 micron stainless steel filter mesh provides the level of filtration needed to ensure the reliability and safety of aerospace equipment.

In the field of water treatment, the 10 micron stainless steel filter mesh is also highly valued for its precision filtration capabilities. Water treatment facilities rely on this mesh to remove impurities and contaminants from water sources, ensuring that the water is safe for consumption. The ultra-reliable nature of the 10 micron stainless steel filter mesh makes it an essential component in water treatment systems around the world.

Overall, the 10 micron stainless steel filter mesh is a versatile and reliable material that is essential for precision work in a variety of industries. Its ability to capture particles as small as 10 microns makes it ideal for applications where precision filtration is required. Whether in industrial filtration, laboratory settings, automotive applications, aerospace, or water treatment, the 10 micron stainless steel filter mesh is a valuable tool for achieving reliable and consistent results.

How to Choose the Right Ultra-Reliable Stainless Steel Filter Mesh for Your Needs

When it comes to precision work, having the right tools and equipment is essential. One key component that can make a significant difference in the quality of your work is the stainless steel filter mesh you use. With so many options available on the market, it can be overwhelming to choose the right one for your specific needs. However, if you are looking for an ultra-reliable option that offers superior performance, a 10 micron stainless steel filter mesh is the way to go.

Stainless steel filter mesh is widely used in various industries, including pharmaceutical, food and beverage, chemical, and automotive, due to its durability, corrosion resistance, and high filtration efficiency. The 10 micron stainless steel filter mesh is particularly popular for applications that require extremely fine filtration, such as in the production of pharmaceuticals, fine chemicals, and high-purity water.

One of the key advantages of using a 10 micron stainless steel filter mesh is its ability to provide precise filtration. With a mesh size of 10 microns, this type of filter can effectively capture particles as small as 10 microns in size, ensuring that only the cleanest and purest liquids pass through. This level of precision is crucial in industries where product quality and purity are of utmost importance.

In addition to its superior filtration capabilities, a 10 micron stainless steel filter mesh is also known for its durability and longevity. Made from high-quality stainless steel, this type of filter mesh is resistant to corrosion, abrasion, and high temperatures, making it ideal for use in harsh and demanding environments. Its robust construction ensures that it can withstand frequent use and cleaning without losing its effectiveness, saving you time and money on replacements.

When choosing a 10 micron stainless steel filter mesh for your specific needs, there are a few key factors to consider. First and foremost, you should determine the size and shape of the filter mesh that will best suit your application. Whether you need a flat sheet, disc, cylinder, or custom-designed filter, make sure to select the right configuration that will fit seamlessly into your existing filtration system.

Another important consideration is the material of the filter mesh. While stainless steel is the most common choice due to its durability and corrosion resistance, there are different grades of stainless steel available, each with its own unique properties. For applications that require high purity and cleanliness, consider opting for a 316 stainless steel filter mesh, which offers superior resistance to chemicals and acids.

Furthermore, it is essential to pay attention to the construction of the filter mesh, including the weave pattern and wire diameter. A tight weave pattern and thicker wire diameter can enhance the strength and filtration efficiency of the mesh, ensuring that it can effectively capture even the smallest particles. Additionally, consider the surface finish of the filter mesh, as a smooth finish can prevent clogging and improve flow rates.

In conclusion, when it comes to precision work that requires ultra-reliable filtration, a 10 micron stainless steel filter mesh is the ideal choice. With its superior filtration capabilities, durability, and longevity, this type of filter mesh can help you achieve the highest level of quality and purity in your products. By considering factors such as size, material, construction, and surface finish, you can select the right filter mesh that will meet your specific needs and exceed your expectations.