Table of Contents

Benefits of Using nylon filter mesh for Filtration Applications

Nylon filter mesh is a versatile and durable material that is commonly used in a wide range of filtration applications. Its unique properties make it an ideal choice for many industries, including food and beverage, pharmaceutical, chemical, and water treatment. In this article, we will explore the different types of nylon filter mesh available on the market and how to choose the right product for your specific filtration needs.

One of the main benefits of using nylon filter mesh is its excellent chemical resistance. Nylon is resistant to a wide range of chemicals, making it suitable for filtering a variety of liquids and gases. This makes it an ideal choice for applications where exposure to harsh chemicals is a concern, such as in the pharmaceutical and chemical industries.

Another key advantage of nylon filter mesh is its high tensile strength. Nylon is a strong and durable material that can withstand high pressures and temperatures, making it suitable for use in demanding filtration applications. Its high tensile strength also ensures that the filter mesh will not break or tear easily, providing long-lasting performance and reliability.

Nylon filter mesh is also known for its excellent abrasion resistance. This makes it ideal for filtering abrasive materials, such as sand, gravel, and other solid particles. The abrasion resistance of nylon filter mesh helps to prolong the life of the filter and ensures that it remains effective over time.

In addition to its chemical resistance, tensile strength, and abrasion resistance, nylon filter mesh is also known for its excellent thermal stability. Nylon can withstand high temperatures without degrading or melting, making it suitable for use in applications where exposure to heat is a concern. This makes nylon filter mesh an ideal choice for filtering hot liquids and gases.

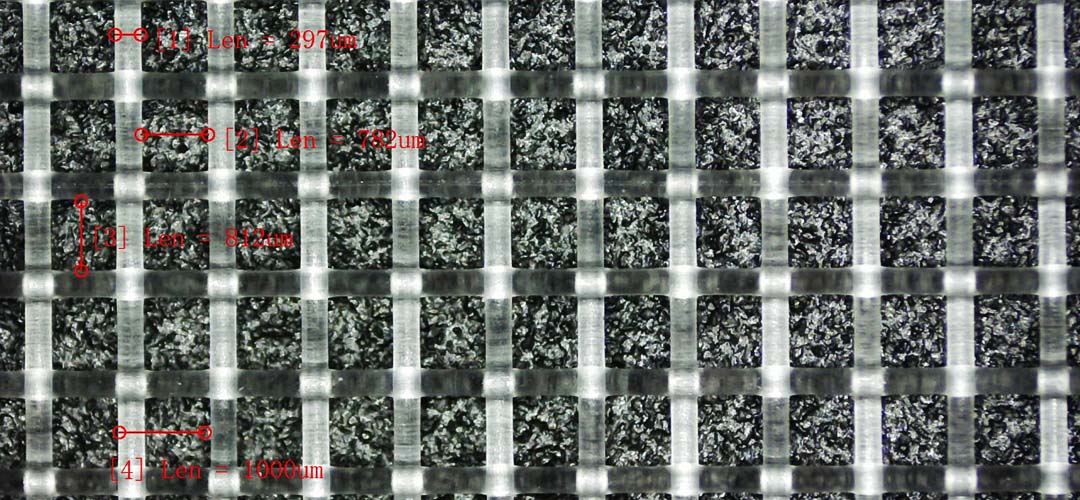

When it comes to choosing the right type of nylon filter mesh for your filtration needs, there are several factors to consider. The first factor to consider is the mesh size. Nylon filter mesh is available in a range of mesh sizes, from fine to coarse. The mesh size you choose will depend on the size of the particles you need to filter out and the flow rate required for your application.

Another factor to consider when choosing nylon filter mesh is the weave type. Nylon filter mesh is available in a variety of weave types, including plain weave, twill weave, and Dutch weave. Each weave type has its own unique characteristics and is suitable for different filtration applications. For example, plain weave nylon filter mesh is ideal for general filtration applications, while Dutch weave nylon filter mesh is suitable for applications that require a high level of filtration efficiency.

In conclusion, nylon filter mesh is a versatile and durable material that is well-suited for a wide range of filtration applications. Its excellent chemical resistance, tensile strength, abrasion resistance, and thermal stability make it an ideal choice for industries such as food and beverage, pharmaceutical, chemical, and water treatment. By considering factors such as mesh size and weave type, you can find the ideal nylon filter mesh product for your specific filtration needs.

Different Types of Nylon Filter Mesh Available in the Market

Nylon filter mesh is a versatile and widely used material in the filtration industry. It is known for its durability, flexibility, and resistance to chemicals and abrasion. Nylon filter mesh is available in various types, each designed for specific filtration needs. In this article, we will explore the different types of nylon filter mesh available in the market to help you find the ideal product for your filtration requirements.

One of the most common types of nylon filter mesh is monofilament nylon mesh. This type of mesh is made from a single continuous filament, which results in a smooth surface and uniform openings. Monofilament nylon mesh is ideal for applications that require high flow rates and precise particle retention. It is commonly used in industries such as food and beverage, pharmaceuticals, and water treatment.

Another type of nylon filter mesh is multifilament nylon mesh. Unlike monofilament nylon mesh, multifilament nylon mesh is made from multiple filaments twisted together. This results in a more porous and flexible mesh that is suitable for applications that require high dirt-holding capacity and good cake release. Multifilament nylon mesh is commonly used in applications such as paint filtration, chemical processing, and wastewater treatment.

In addition to monofilament and multifilament nylon mesh, there are also specialty nylon filter meshes available in the market. These include conductive nylon mesh, which is designed for applications that require static dissipation, and antistatic nylon mesh, which is ideal for applications that require protection against static electricity. Specialty nylon filter meshes are used in industries such as electronics, automotive, and aerospace.

When choosing a nylon filter mesh for your filtration needs, it is important to consider factors such as mesh size, pore size, and filtration efficiency. Mesh size refers to the number of openings per inch in the mesh, while pore size refers to the size of the openings. Filtration efficiency refers to the ability of the mesh to retain particles of a certain size.

It is also important to consider the compatibility of the nylon filter mesh with the chemicals and temperatures involved in the filtration process. Nylon filter mesh is resistant to a wide range of chemicals, but it may degrade when exposed to certain solvents or high temperatures. It is important to consult with a filtration expert to ensure that you choose the right type of nylon filter mesh for your specific application.

In conclusion, nylon filter mesh is a versatile and durable material that is widely used in the filtration industry. There are different types of nylon filter mesh available in the market, each designed for specific filtration needs. By considering factors such as mesh size, pore size, filtration efficiency, and compatibility with chemicals and temperatures, you can find the ideal product for your filtration requirements. Consult with a filtration expert to help you choose the right type of nylon filter mesh for your application.

How to Choose the Right Nylon Filter Mesh for Your Specific Filtration Needs

Nylon filter mesh is a versatile and durable material that is commonly used in a variety of filtration applications. From industrial processes to laboratory settings, nylon filter mesh is known for its strength, flexibility, and resistance to chemicals and abrasion. When it comes to choosing the right nylon filter mesh for your specific filtration needs, there are several factors to consider. In this article, we will explore the different types of nylon filter mesh available on the market and provide guidance on how to select the ideal product for your filtration requirements.

One of the first things to consider when choosing a nylon filter mesh is the mesh size. Mesh size refers to the number of openings per inch in the mesh material. The smaller the mesh size, the finer the filtration capabilities of the mesh. For applications that require fine filtration, such as removing particles or debris from liquids or gases, a nylon filter mesh with a smaller mesh size is recommended. On the other hand, for applications that require larger particles to pass through the mesh, a nylon filter mesh with a larger mesh size may be more suitable.

Another important factor to consider when selecting a nylon filter mesh is the mesh weave. The weave of the mesh refers to the pattern in which the strands of nylon are intertwined to create the mesh material. Common weave patterns include plain weave, twill weave, and Dutch weave. Each weave pattern offers different filtration properties, such as strength, flexibility, and particle retention. For example, a plain weave nylon filter mesh is ideal for general filtration applications, while a Dutch weave nylon filter mesh is better suited for applications that require precise particle retention.

In addition to mesh size and weave pattern, it is important to consider the micron rating of the nylon filter mesh. The micron rating indicates the size of particles that the mesh can effectively filter out. A lower micron rating indicates a finer filtration capability, while a higher micron rating indicates a coarser filtration capability. When selecting a nylon filter mesh, it is important to choose a micron rating that is appropriate for the size of particles that need to be filtered out in your specific application.

Furthermore, the material of the nylon filter mesh should also be taken into consideration. Nylon filter mesh is available in a variety of materials, including nylon 6 and nylon 6/6. Nylon 6 is known for its high tensile strength and resistance to abrasion, making it ideal for applications that require durability and longevity. On the other hand, nylon 6/6 is known for its chemical resistance and thermal stability, making it suitable for applications that involve exposure to harsh chemicals or high temperatures.

In conclusion, when it comes to choosing the right nylon filter mesh for your specific filtration needs, it is important to consider factors such as mesh size, weave pattern, micron rating, and material. By taking these factors into account, you can select the ideal nylon filter mesh that will provide efficient and effective filtration for your application. Whether you are filtering liquids, gases, or particles, there is a nylon filter mesh available that is tailored to meet your specific filtration requirements.