Table of Contents

Automotive Industry: Enhancing Filtration Systems with nylon mesh

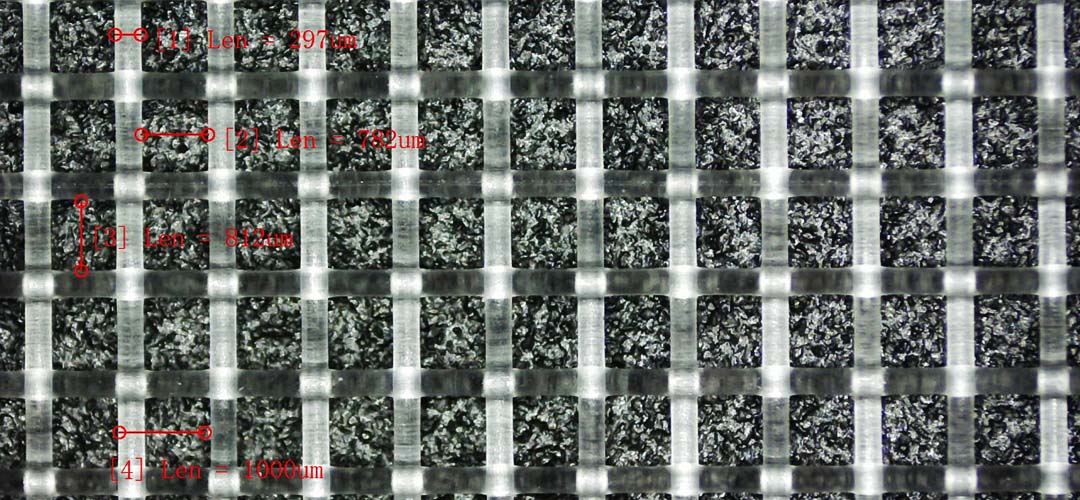

Nylon mesh has emerged as a critical component in the automotive industry, particularly in enhancing filtration systems. As vehicles become more sophisticated, the demand for efficient filtration solutions has surged, leading manufacturers to seek materials that offer durability, flexibility, and superior filtration capabilities. Nylon mesh, with its unique properties, has proven to be an ideal choice for various applications within the automotive sector.

One of the primary uses of nylon mesh in automotive filtration systems is in air filters. These filters are essential for maintaining optimal engine performance and ensuring that harmful particles do not enter the engine. The fine mesh structure of nylon allows for the effective trapping of dust, dirt, and other contaminants while still permitting adequate airflow. This balance is crucial, as it helps to enhance fuel efficiency and reduce emissions, aligning with the industry’s increasing focus on sustainability and environmental responsibility.

Moreover, nylon mesh is also utilized in fuel filtration systems. The automotive industry has seen a shift towards more advanced fuel systems that require precise filtration to prevent impurities from damaging sensitive engine components. Nylon mesh filters are capable of withstanding the harsh chemical environment of fuel systems, providing reliable performance over extended periods. This durability not only extends the lifespan of the filters but also reduces maintenance costs for vehicle owners, making nylon mesh a cost-effective solution for manufacturers.

In addition to air and fuel filtration, nylon mesh plays a significant role in hydraulic systems within vehicles. These systems are critical for the operation of various components, including brakes and power steering. The use of nylon mesh in hydraulic filters ensures that contaminants are effectively removed from the fluid, which is vital for maintaining the integrity and performance of these systems. By preventing the buildup of debris, nylon mesh contributes to the overall safety and reliability of vehicles, which is a top priority for manufacturers and consumers alike.

The versatility of nylon mesh extends beyond traditional filtration applications. In recent years, the automotive industry has begun to explore innovative uses for this material, such as in the development of composite materials that enhance structural integrity while providing filtration capabilities. This trend reflects a broader movement towards integrating multifunctional materials into vehicle design, allowing for lighter, more efficient vehicles without compromising performance.

As the automotive industry continues to evolve, the reliance on advanced materials like nylon mesh is expected to grow. Manufacturers are increasingly recognizing the importance of high-performance filtration systems in meeting regulatory standards and consumer expectations. The ability of nylon mesh to provide effective filtration while being lightweight and resistant to various environmental factors makes it an invaluable asset in the quest for improved vehicle performance and sustainability.

In conclusion, the automotive industry is significantly benefiting from the incorporation of nylon mesh in filtration systems. Its applications in air, fuel, and hydraulic filtration not only enhance the performance and reliability of vehicles but also contribute to cost savings and environmental sustainability. As the industry moves towards more innovative and efficient designs, the role of nylon mesh is likely to expand, solidifying its position as a key material in automotive engineering. The ongoing advancements in nylon mesh technology will undoubtedly continue to support the industry’s goals of enhancing vehicle performance while adhering to stringent environmental standards.

Water Treatment: The Role of Nylon Mesh in Efficient Filtration

Nylon mesh has become a crucial component in various industries, especially in water treatment. Its versatility, durability, and efficiency make it an ideal material for filter netting solutions. In this article, we will explore the top industries that rely on nylon mesh for their filtration needs.

Water treatment is a critical process in many industries, including municipal water treatment plants, industrial facilities, and even residential homes. The role of nylon mesh in efficient filtration cannot be understated. Nylon mesh filters are used to remove impurities, contaminants, and particles from water, ensuring that it is safe for consumption and meets regulatory standards.

One of the top industries that heavily rely on nylon mesh for filter netting solutions is the pharmaceutical industry. Pharmaceutical companies require high-quality water for their manufacturing processes to ensure the purity and safety of their products. Nylon mesh filters are used to remove bacteria, viruses, and other contaminants from water, ensuring that it meets the stringent requirements of the pharmaceutical industry.

Another industry that relies on nylon mesh for filtration is the food and beverage industry. Food and beverage manufacturers require clean and pure water for their production processes to ensure the quality and safety of their products. Nylon mesh filters are used to remove impurities, sediments, and other contaminants from water, ensuring that it meets the strict standards of the food and beverage industry.

The automotive industry is also a major user of nylon mesh for filter netting solutions. Automotive manufacturers require clean water for their manufacturing processes to ensure the quality and performance of their vehicles. Nylon mesh filters are used to remove oil, grease, and other contaminants from water, ensuring that it meets the high standards of the automotive industry.

In addition to these industries, the textile industry also relies on nylon mesh for filtration. Textile manufacturers require clean water for their dyeing and finishing processes to ensure the quality and colorfastness of their fabrics. Nylon mesh filters are used to remove dyes, chemicals, and other impurities from water, ensuring that it meets the stringent requirements of the textile industry.

Overall, nylon mesh plays a crucial role in efficient filtration in various industries, including water treatment, pharmaceuticals, food and beverage, automotive, and textiles. Its versatility, durability, and efficiency make it an ideal material for filter netting solutions. As industries continue to evolve and grow, the demand for high-quality filtration solutions will only increase, further solidifying the importance of nylon mesh in today’s industrial landscape.

Food and Beverage: Ensuring Safety with nylon mesh filter Solutions

Nylon mesh has emerged as a critical component in the food and beverage industry, particularly in the realm of filter netting solutions. As the demand for high-quality, safe, and efficient filtration systems continues to rise, nylon mesh offers a versatile and reliable option that meets the stringent requirements of this sector. The unique properties of nylon, including its strength, durability, and resistance to chemicals, make it an ideal material for various applications, from processing to packaging.

In food and beverage processing, the need for effective filtration cannot be overstated. Contaminants such as dust, debris, and microorganisms can compromise product quality and safety. Therefore, manufacturers are increasingly turning to nylon mesh filters to ensure that their products meet regulatory standards and consumer expectations. The fine mesh structure of nylon allows for precise filtration, effectively removing unwanted particles while maintaining the integrity of the liquid being processed. This capability is particularly important in industries such as juice production, where clarity and purity are paramount.

Moreover, nylon mesh is not only effective in filtration but also offers excellent resistance to high temperatures and various chemicals. This characteristic is crucial in the food and beverage industry, where processes often involve exposure to heat and aggressive cleaning agents. The ability of nylon mesh to withstand these conditions without degrading ensures that filtration systems remain operational and effective over time. As a result, businesses can reduce downtime and maintenance costs, ultimately leading to increased productivity and profitability.

In addition to processing, nylon mesh plays a significant role in packaging applications within the food and beverage sector. The use of nylon mesh in packaging materials helps to extend shelf life by providing a barrier against contaminants while allowing for breathability. This is particularly beneficial for products such as fresh produce, where moisture control is essential to prevent spoilage. By incorporating nylon mesh into packaging solutions, companies can enhance product quality and reduce waste, aligning with sustainability goals that are increasingly important to consumers.

Furthermore, the versatility of nylon mesh allows for customization to meet specific industry needs. Manufacturers can produce nylon mesh filters in various sizes, shapes, and mesh counts, enabling businesses to tailor their filtration solutions to their unique processes. This adaptability is a significant advantage in a market where one-size-fits-all solutions often fall short. By utilizing nylon mesh, companies can optimize their filtration systems, ensuring that they achieve the desired level of purity and safety for their products.

As the food and beverage industry continues to evolve, the reliance on innovative materials like nylon mesh will only grow. With increasing consumer awareness regarding food safety and quality, businesses must prioritize effective filtration solutions to maintain their competitive edge. Nylon mesh not only meets these demands but also supports the industry’s commitment to sustainability and efficiency. By investing in nylon mesh filter netting solutions, companies can enhance their operational capabilities while ensuring that they deliver safe, high-quality products to consumers.

In conclusion, nylon mesh has established itself as an indispensable material in the food and beverage industry, particularly for filter netting solutions. Its unique properties, including strength, durability, and chemical resistance, make it ideal for various applications, from processing to packaging. As businesses strive to meet regulatory standards and consumer expectations, the adoption of nylon mesh will continue to play a pivotal role in ensuring safety and quality in food and beverage products.