Table of Contents

Benefits of Using 100 micron nylon filter cloth for Ensuring Reliable Performance

The use of 100 micron nylon filter cloth has become increasingly prevalent across various industries, primarily due to its exceptional reliability and performance. This material is engineered to provide a high level of filtration efficiency, making it an ideal choice for applications that require the separation of fine particles from liquids or gases. One of the most significant benefits of utilizing 100 micron nylon filter cloth is its ability to maintain consistent performance under varying operational conditions. This reliability is crucial in industries such as pharmaceuticals, food and beverage, and chemical processing, where even minor fluctuations in filtration quality can lead to significant operational challenges.

Moreover, the durability of nylon as a material contributes to the overall effectiveness of the filter cloth. Unlike other materials that may degrade or lose their structural integrity over time, 100 micron nylon filter cloth is resistant to wear and tear, ensuring a longer lifespan. This durability not only reduces the frequency of replacements but also minimizes downtime, allowing businesses to maintain productivity and efficiency. Consequently, organizations can achieve substantial cost savings over time, as the need for frequent maintenance and replacement is significantly diminished.

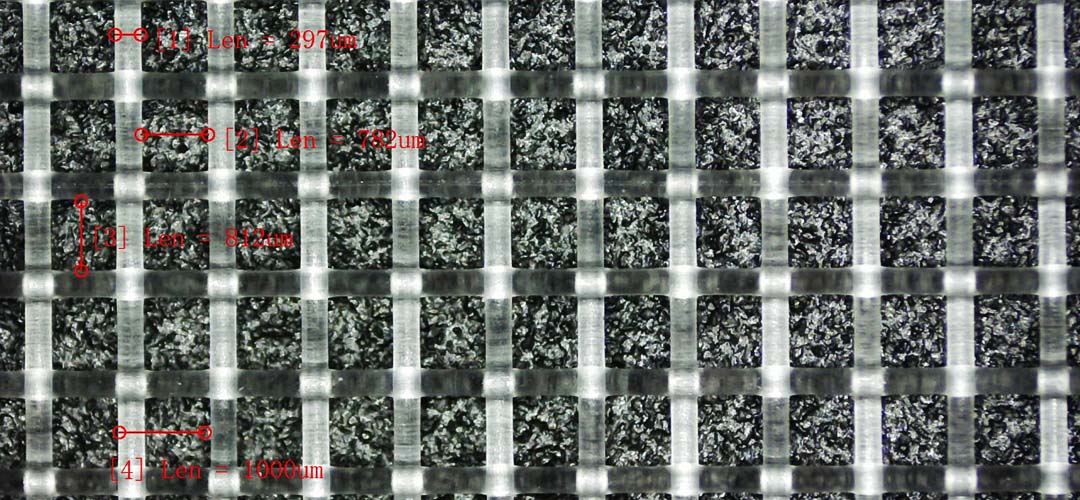

In addition to its durability, the 100 micron specification offers a balanced filtration capability that is particularly advantageous for various applications. The micron rating indicates the size of particles that the filter can effectively capture, and at 100 microns, this filter cloth strikes an optimal balance between filtration efficiency and flow rate. This means that while it effectively removes unwanted particles, it does not overly restrict the flow of liquids or gases, thereby ensuring that processes remain efficient and uninterrupted. This characteristic is especially important in industries where maintaining a steady flow is critical to operational success.

Furthermore, the versatility of 100 micron nylon filter cloth cannot be overlooked. It can be utilized in a wide range of applications, from liquid filtration in wastewater treatment to air filtration in industrial settings. This adaptability makes it a valuable asset for companies looking to streamline their operations with a single type of filter cloth that can meet multiple needs. As businesses increasingly seek to optimize their processes, the ability to rely on a single filtration solution can lead to enhanced operational efficiency and reduced complexity in supply chain management.

Another noteworthy benefit of 100 micron nylon filter cloth is its ease of cleaning and maintenance. Many industries require filters to be cleaned regularly to maintain their effectiveness, and nylon filter cloth can be easily washed and reused without significant loss of performance. This feature not only contributes to sustainability efforts by reducing waste but also aligns with the growing emphasis on environmentally friendly practices in business operations. By choosing a filter cloth that can be reused multiple times, companies can demonstrate their commitment to sustainability while also benefiting from reduced operational costs.

In conclusion, the advantages of using 100 micron nylon filter cloth for ensuring reliable performance are manifold. Its durability, filtration efficiency, versatility, and ease of maintenance make it an indispensable component in various industrial applications. As businesses continue to prioritize efficiency and sustainability, the adoption of 100 micron nylon filter cloth is likely to grow, solidifying its position as a preferred choice for reliable filtration solutions. By investing in this high-quality material, organizations can enhance their operational performance while also contributing to a more sustainable future.

How to Choose the Right 100 Micron Nylon Filter Cloth for Optimal Performance

When it comes to choosing the right filter cloth for your filtration needs, there are a variety of factors to consider. One important factor to take into account is the micron rating of the filter cloth. Micron rating refers to the size of the openings in the filter cloth, which determines the size of particles that can pass through the cloth. A 100 micron nylon filter cloth is a popular choice for many applications due to its reliable performance and versatility.

One of the key benefits of using a 100 micron nylon filter cloth is its ability to effectively capture a wide range of particle sizes. The 100 micron rating means that the filter cloth can capture particles as small as 100 microns in size, making it suitable for a variety of filtration tasks. Whether you are filtering large particles or fine particles, a 100 micron nylon filter cloth can provide the filtration efficiency you need.

In addition to its versatility, a 100 micron nylon filter cloth is also known for its durability and longevity. Nylon is a strong and resilient material that can withstand high temperatures and harsh chemicals, making it ideal for use in demanding filtration applications. With proper care and maintenance, a 100 micron nylon filter cloth can provide reliable performance for an extended period of time, saving you time and money on frequent replacements.

When choosing a 100 micron nylon filter cloth, it is important to consider the specific requirements of your filtration application. Different types of nylon filter cloths are available, each with its own unique characteristics and performance capabilities. Some nylon filter cloths are treated with special coatings to enhance their filtration efficiency, while others are designed for specific applications such as oil filtration or water treatment.

It is also important to consider the size and shape of the filter cloth when selecting a 100 micron nylon filter cloth. The filter cloth should be sized to fit your filtration equipment properly, ensuring a tight seal and efficient filtration. Additionally, the shape of the filter cloth can impact its performance, with options such as round discs, filter bags, and filter cartridges available to suit different filtration needs.

In conclusion, a 100 micron nylon filter cloth is a reliable and versatile choice for a wide range of filtration applications. Its ability to capture particles of various sizes, combined with its durability and longevity, make it a popular option for many industries. By considering the specific requirements of your filtration application and selecting the right type and size of filter cloth, you can ensure optimal performance and efficiency in your filtration process. Whether you are filtering water, oil, chemicals, or other substances, a 100 micron nylon filter cloth can help you achieve the results you need.

Case Studies Highlighting the Importance of Reliable Performance with 100 Micron Nylon Filter Cloth

In the world of industrial filtration, the performance of filter cloth is crucial to the success of any operation. One type of filter cloth that has gained popularity for its reliability and efficiency is 100 micron nylon filter cloth. This type of filter cloth is known for its ability to effectively capture particles as small as 100 microns, making it ideal for a wide range of applications.

One case study that highlights the importance of reliable performance with 100 micron nylon filter cloth comes from a manufacturing plant that produces chemicals for various industries. The plant was experiencing issues with their current filter cloth, which was failing to effectively capture particles of a certain size, leading to contamination in their final product. After switching to 100 micron nylon filter cloth, the plant saw a significant improvement in the quality of their product, as the filter cloth was able to capture even the smallest particles, ensuring a clean and pure final product.

Another case study comes from a wastewater treatment plant that was struggling with high levels of contamination in their effluent. The plant had tried various types of filter cloth, but none were able to effectively remove the contaminants from the water. After switching to 100 micron nylon filter cloth, the plant saw a dramatic improvement in the quality of their effluent, with significantly lower levels of contamination. This not only improved the overall efficiency of the plant but also helped them meet regulatory standards for water quality.

In both of these case studies, the key takeaway is the importance of reliable performance when it comes to filter cloth. 100 micron nylon filter cloth has proven time and time again to be a reliable and effective solution for a wide range of filtration needs. Its ability to capture particles as small as 100 microns makes it a versatile option for industries ranging from chemical manufacturing to wastewater treatment.

One of the main reasons why 100 micron nylon filter cloth is so effective is its durability. Unlike other types of filter cloth that may degrade over time, 100 micron nylon filter cloth is designed to withstand the rigors of industrial filtration. This means that it can be used for extended periods without losing its effectiveness, saving companies time and money on frequent replacements.

Additionally, 100 micron nylon filter cloth is easy to clean and maintain, further adding to its reliability. Regular cleaning and maintenance of filter cloth are essential to ensure optimal performance, and 100 micron nylon filter cloth makes this process simple and straightforward. This means that companies can spend less time worrying about their filtration system and more time focusing on their core operations.

Overall, the case studies highlighted here demonstrate the importance of reliable performance when it comes to filter cloth. 100 micron nylon filter cloth has proven to be a dependable and efficient solution for a wide range of industries, from chemical manufacturing to wastewater treatment. Its ability to capture particles as small as 100 microns, combined with its durability and ease of maintenance, make it an ideal choice for companies looking to improve the quality and efficiency of their filtration systems.