Table of Contents

Benefits of Using Reliable 250 Micron Screens for Industrial Filtration

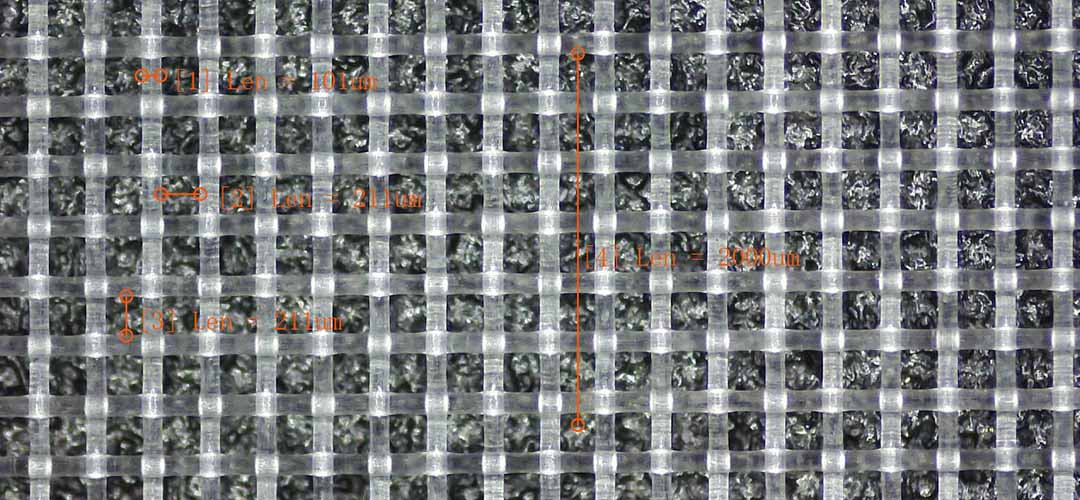

In the world of industrial filtration, having reliable equipment is crucial to ensuring the efficiency and effectiveness of the filtration process. One key component of this process is the use of 250 micron screens, which play a vital role in separating particles and contaminants from liquids and gases. These screens are designed to capture particles that are 250 microns or larger in size, making them ideal for a wide range of industrial applications.

One of the primary benefits of using reliable 250 micron screens is their ability to effectively remove large particles from the filtration process. By capturing particles that are 250 microns or larger in size, these screens help to prevent clogs and blockages in the filtration system, which can lead to costly downtime and maintenance issues. This ensures that the filtration process runs smoothly and efficiently, allowing for continuous operation without interruptions.

Another key benefit of using reliable 250 micron screens is their durability and longevity. These screens are typically made from high-quality materials that are designed to withstand the harsh conditions of industrial environments. This means that they are able to withstand high temperatures, corrosive chemicals, and heavy loads without experiencing wear and tear. As a result, they offer a long service life and require minimal maintenance, saving time and money in the long run.

In addition to their durability, reliable 250 micron screens also offer excellent filtration performance. These screens are designed to provide a high level of filtration efficiency, capturing a wide range of particles and contaminants to ensure that the end product meets the required quality standards. This makes them ideal for a variety of industrial applications, including water treatment, oil and gas processing, food and beverage production, and more.

Furthermore, reliable 250 micron screens are easy to install and maintain, making them a cost-effective solution for industrial filtration applications. These screens are typically designed to be compatible with a wide range of filtration systems, allowing for easy integration into existing processes. Additionally, their simple design and construction make them easy to clean and maintain, reducing the need for frequent replacements and repairs.

Overall, the use of reliable 250 micron screens offers a number of benefits for industrial filtration applications. From their ability to effectively remove large particles to their durability, longevity, and excellent filtration performance, these screens are an essential component of any industrial filtration system. By investing in high-quality 250 micron screens, businesses can ensure that their filtration processes run smoothly and efficiently, leading to improved productivity, reduced downtime, and cost savings in the long run.

How to Choose the Right Reliable 250 micron screen for Your Application

When it comes to industrial filtration applications, choosing the right screen is crucial for ensuring optimal performance and efficiency. One popular option for many industries is the 250 micron screen, known for its reliability and effectiveness in filtering out particles of a certain size. However, with so many options available on the market, it can be overwhelming to select the best screen for your specific application. In this article, we will discuss some key factors to consider when choosing a reliable 250 micron screen for your industrial filtration needs.

First and foremost, it is important to understand the requirements of your application. Consider the type of particles you need to filter out, as well as the flow rate and pressure of your system. Different screens are designed to handle different types of particles and flow rates, so it is essential to choose a screen that can effectively meet the demands of your specific application.

Another important factor to consider is the material of the screen. 250 micron screens are typically made from stainless steel, but there are also options available in other materials such as nylon or polyester. The material of the screen will impact its durability, chemical resistance, and overall performance. For example, stainless steel screens are known for their strength and longevity, making them a popular choice for industrial applications where durability is key.

In addition to material, the construction of the screen is also an important consideration. Look for screens that are well-constructed with tight tolerances to ensure consistent and reliable performance. Screens with reinforced edges or frames can also help prevent damage and prolong the life of the screen, especially in high-pressure or high-temperature applications.

When selecting a 250 micron screen, it is also important to consider the mesh size. The mesh size refers to the number of openings per inch in the screen, with a higher mesh count indicating smaller openings and finer filtration. For industrial applications that require precise filtration of small particles, a higher mesh count may be necessary. However, keep in mind that a higher mesh count can also result in reduced flow rates, so it is important to strike a balance between filtration efficiency and system performance.

Finally, consider the maintenance requirements of the screen. Some screens may require regular cleaning or replacement to maintain optimal performance, while others are designed for long-term use with minimal maintenance. Consider your operational needs and budget when choosing a screen that aligns with your maintenance schedule and requirements.

In conclusion, choosing a reliable 250 micron screen for your industrial filtration application requires careful consideration of factors such as material, construction, mesh size, and maintenance requirements. By understanding the specific needs of your application and selecting a screen that meets those requirements, you can ensure efficient and effective filtration for your industrial processes. With the right screen in place, you can improve the performance and longevity of your filtration system, ultimately leading to cost savings and increased productivity in your operations.

Maintenance Tips for Ensuring Longevity of Reliable 250 Micron Screens

When it comes to industrial filtration applications, having reliable equipment is crucial for ensuring smooth operations and high-quality results. One key component of many filtration systems is the 250 micron screen, which plays a vital role in removing impurities and contaminants from liquids and gases. These screens are designed to trap particles that are larger than 250 microns in size, allowing only clean fluid to pass through.

To ensure the longevity and effectiveness of your 250 micron screens, proper maintenance is essential. Regular cleaning and inspection are necessary to prevent clogging and damage, which can lead to decreased filtration efficiency and costly repairs. By following these maintenance tips, you can extend the lifespan of your screens and keep your filtration system running smoothly.

First and foremost, it is important to establish a regular cleaning schedule for your 250 micron screens. Depending on the volume and type of contaminants being filtered, screens may need to be cleaned daily, weekly, or monthly. It is crucial to remove any buildup of particles and debris that can clog the screen and impede filtration. This can be done using a soft brush or cloth to gently scrub the surface of the screen, being careful not to damage the mesh.

In addition to regular cleaning, it is also important to inspect the screens for any signs of damage or wear. Check for tears, holes, or bent edges that can compromise the integrity of the screen. If any damage is found, it is important to replace the screen immediately to prevent further issues. Keeping spare screens on hand can help minimize downtime and ensure that your filtration system continues to operate efficiently.

Another important maintenance tip is to monitor the pressure differential across the screen. A significant increase in pressure drop can indicate that the screen is becoming clogged and may need to be cleaned or replaced. By regularly monitoring the pressure differential, you can identify potential issues before they impact the performance of your filtration system.

In addition to cleaning and inspection, it is important to handle and store your 250 micron screens properly. Avoid dropping or mishandling the screens, as this can cause damage to the mesh. Store screens in a clean, dry area away from direct sunlight and extreme temperatures to prevent degradation of the material. Proper handling and storage practices can help prolong the lifespan of your screens and ensure consistent filtration performance.

By following these maintenance tips, you can ensure the longevity and effectiveness of your 250 micron screens for industrial filtration applications. Regular cleaning, inspection, and monitoring are essential for preventing clogging and damage, while proper handling and storage practices can help extend the lifespan of your screens. With proper maintenance, you can keep your filtration system running smoothly and efficiently, ensuring high-quality results and minimizing downtime.