Table of Contents

Benefits of Using Reliable 200 micron nylon mesh in Industrial Filtration Processes

When it comes to industrial filtration processes, having reliable equipment is crucial to ensure the efficiency and effectiveness of the operation. One key component that plays a significant role in filtration is the mesh used in the process. A 200 micron nylon mesh is a popular choice for many industries due to its durability, versatility, and efficiency in filtering out particles of various sizes.

One of the main benefits of using a 200 micron nylon mesh is its reliability. Nylon is a strong and durable material that can withstand high temperatures and pressures, making it ideal for industrial applications. The 200 micron size is also versatile enough to capture a wide range of particle sizes, making it suitable for a variety of filtration needs.

In addition to its durability, nylon mesh is also known for its flexibility. It can be easily molded and shaped to fit different filtration systems, making it a versatile option for a wide range of applications. This flexibility allows for customization to meet specific filtration requirements, ensuring optimal performance in any industrial setting.

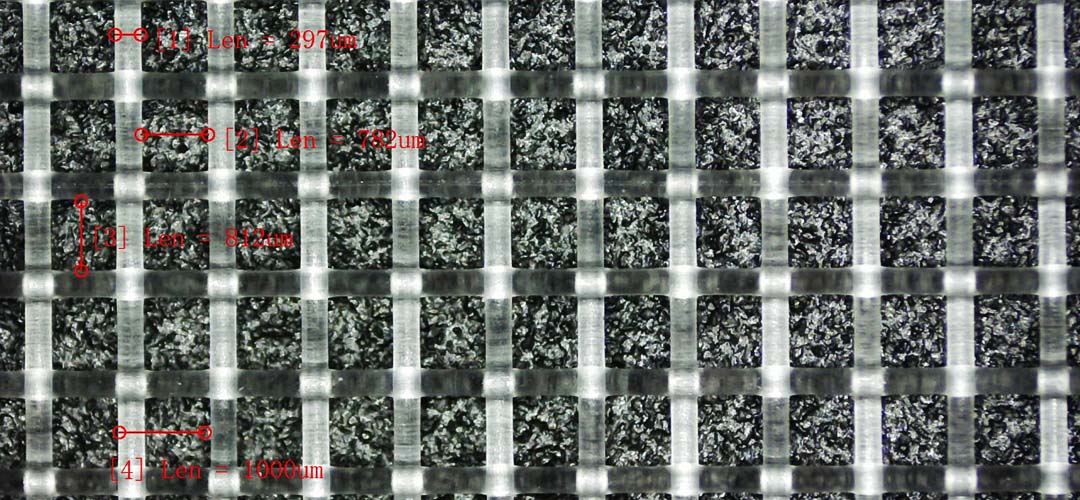

Another advantage of using a 200 micron nylon mesh is its efficiency in filtering out particles. The small mesh size of 200 microns allows for the capture of fine particles while still maintaining a high flow rate. This means that the mesh can effectively remove contaminants from liquids or gases without causing a significant drop in pressure, ensuring smooth and efficient filtration processes.

Furthermore, nylon mesh is easy to clean and maintain, making it a cost-effective option for industrial filtration systems. Regular cleaning and maintenance can prolong the lifespan of the mesh, reducing the need for frequent replacements and saving on operational costs in the long run.

The versatility of a 200 micron nylon mesh also makes it suitable for a wide range of applications. From water treatment and food processing to pharmaceuticals and chemical industries, this type of mesh can be used in various filtration processes to ensure the purity and quality of the final product.

In conclusion, the benefits of using a reliable 200 micron nylon mesh in industrial filtration processes are clear. Its durability, flexibility, efficiency, and versatility make it a top choice for many industries looking to improve their filtration systems. By investing in high-quality nylon mesh, businesses can ensure the smooth operation of their filtration processes and achieve optimal results in their production processes.

How Reliable 200 Micron Nylon Mesh Improves Efficiency in Aquaculture Systems

When it comes to aquaculture systems, having reliable equipment is essential for ensuring the efficiency and success of your operation. One key component that plays a crucial role in aquaculture systems is the mesh used for filtration and separation purposes. 200 micron nylon mesh has proven to be a reliable and versatile option for a wide range of applications in aquaculture systems.

One of the main advantages of using 200 micron nylon mesh is its durability and strength. Nylon is known for its high tensile strength and resistance to abrasion, making it ideal for withstanding the harsh conditions often found in aquaculture systems. This means that the mesh is less likely to tear or break, ensuring that it can withstand the rigors of continuous use.

In addition to its durability, 200 micron nylon mesh is also highly effective at filtering out particles of various sizes. The small mesh size of 200 microns allows for efficient filtration of fine particles, ensuring that the water in the aquaculture system remains clean and free of debris. This is crucial for maintaining the health and well-being of the aquatic organisms being raised in the system.

Furthermore, the uniformity of the mesh size in 200 micron nylon mesh ensures consistent filtration performance. This means that you can rely on the mesh to consistently remove particles of a certain size, without any fluctuations or inconsistencies. This level of reliability is essential for ensuring the overall efficiency of the aquaculture system.

Another key benefit of using 200 micron nylon mesh is its versatility. This type of mesh can be used for a wide range of applications in aquaculture systems, including filtration, separation, and containment. Whether you need to filter out solids from water, separate different species of aquatic organisms, or contain fish or shrimp within a specific area, 200 micron nylon mesh can meet your needs.

The versatility of 200 micron nylon mesh also extends to its compatibility with different types of aquaculture systems. Whether you are operating a recirculating aquaculture system, a flow-through system, or a pond-based system, 200 micron nylon mesh can be easily integrated into your setup. This flexibility makes it a practical choice for aquaculture operators looking to improve the efficiency of their systems.

In conclusion, 200 micron nylon mesh is a reliable and versatile option for a wide range of applications in aquaculture systems. Its durability, strength, and effectiveness at filtering out particles make it an essential component for maintaining the efficiency and success of your operation. By investing in high-quality 200 micron nylon mesh, you can ensure that your aquaculture system operates smoothly and effectively, leading to better outcomes for your aquatic organisms and your business as a whole.

Applications of Reliable 200 Micron Nylon Mesh in the Medical Industry

Nylon mesh is a versatile material that finds applications in a wide range of industries, including the medical field. One of the most popular choices for medical applications is the 200 micron nylon mesh, known for its reliability and durability. This type of mesh is commonly used in various medical devices and equipment due to its excellent filtration properties and strength.

In the medical industry, the 200 micron nylon mesh is often used in filtration systems for blood transfusion, pharmaceutical manufacturing, and laboratory testing. Its fine mesh size allows for efficient filtration of particles and contaminants, ensuring the purity and safety of medical products. The nylon material is also resistant to chemicals and high temperatures, making it suitable for sterilization processes commonly used in medical settings.

Another common application of the 200 micron nylon mesh in the medical industry is in wound care products. The mesh is used as a support material for wound dressings, providing a barrier against bacteria and other contaminants while allowing for proper airflow and drainage. Its soft and flexible nature makes it comfortable for patients to wear, while its durability ensures that the dressing remains intact during the healing process.

Surgical instruments and implants also benefit from the use of 200 micron nylon mesh. The material is often used as a reinforcement layer in surgical gloves, ensuring a secure grip and protection against punctures. In implants, the mesh provides structural support and promotes tissue ingrowth, leading to better integration with the surrounding tissue. Its biocompatibility and non-reactive nature make it a safe choice for use in the human body.

In addition to its use in medical devices and equipment, the 200 micron nylon mesh is also employed in research and development within the medical field. Researchers use the mesh in laboratory settings for cell culture studies, drug delivery systems, and tissue engineering applications. Its uniform pore size and high porosity allow for precise control over the flow of fluids and substances, making it an ideal material for experimental purposes.

Overall, the 200 micron nylon mesh is a reliable and versatile material that plays a crucial role in various applications within the medical industry. Its strength, durability, and filtration properties make it a preferred choice for medical devices, wound care products, surgical instruments, implants, and research purposes. With its ability to withstand harsh conditions and maintain its integrity over time, this type of nylon mesh continues to be a valuable asset in advancing medical technology and improving patient care.