Table of Contents

Benefits of Using Reliable 100 Mesh Filter Screens in Industrial Applications

When it comes to industrial applications, having reliable filtration systems in place is crucial for ensuring the efficiency and longevity of equipment. One key component of any filtration system is the filter screen, which plays a vital role in removing impurities and contaminants from liquids and gases. In industrial settings, where the stakes are high and the demands are rigorous, having a reliable 100 mesh filter screen can make all the difference.

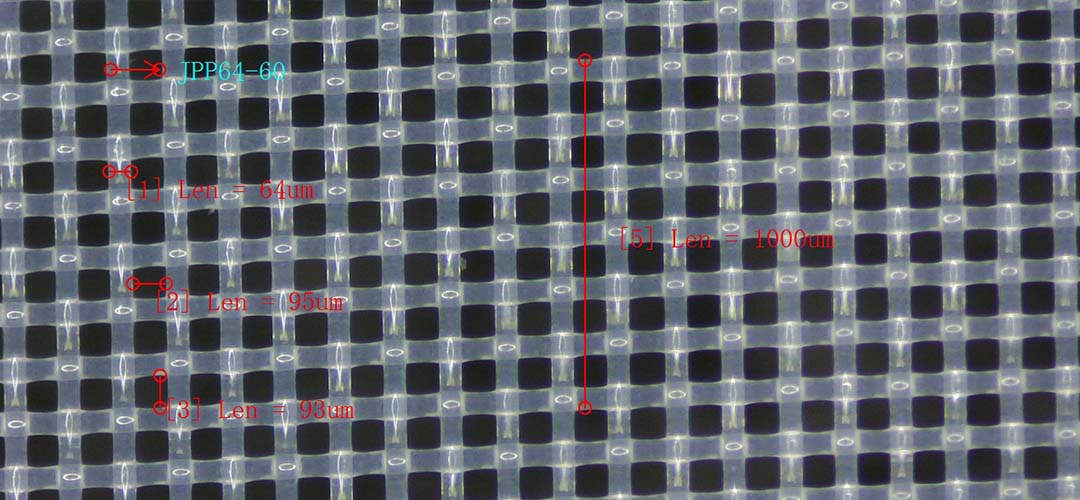

One of the primary benefits of using a 100 mesh filter screen in industrial applications is its ability to effectively capture and remove particles as small as 0.0055 inches in diameter. This level of filtration is essential for industries such as oil and gas, chemical processing, and water treatment, where even the smallest impurities can cause significant damage to equipment and compromise product quality. By using a 100 mesh filter screen, companies can ensure that their processes run smoothly and efficiently, without the risk of contamination or equipment failure.

Another key benefit of using a reliable 100 mesh filter screen is its durability and longevity. Industrial applications can be harsh and demanding, with high temperatures, corrosive chemicals, and abrasive materials posing a constant threat to equipment and filtration systems. A 100 mesh filter screen made from high-quality materials such as stainless steel or brass can withstand these harsh conditions and continue to perform effectively over time. This durability not only reduces the need for frequent replacements and maintenance but also ensures that the filtration system remains reliable and efficient in the long run.

In addition to its filtration capabilities and durability, a 100 mesh filter screen offers the added benefit of versatility. These screens can be customized to fit a wide range of industrial equipment and applications, making them a versatile and cost-effective solution for companies with diverse filtration needs. Whether used in a pressure vessel, a pipeline, or a filtration unit, a 100 mesh filter screen can be tailored to meet specific requirements and ensure optimal performance in any setting.

Furthermore, using a reliable 100 mesh filter screen in industrial applications can lead to cost savings and increased efficiency. By effectively removing impurities and contaminants from liquids and gases, these screens help prevent equipment damage, reduce downtime, and improve product quality. This, in turn, can result in lower maintenance costs, higher productivity, and greater customer satisfaction, ultimately leading to a more profitable and competitive business.

In conclusion, the benefits of using a reliable 100 mesh filter screen in industrial applications are clear. From its superior filtration capabilities and durability to its versatility and cost-effectiveness, a 100 mesh filter screen is an essential component of any filtration system in industries where precision and reliability are paramount. By investing in high-quality filter screens and ensuring their proper maintenance and replacement, companies can safeguard their equipment, optimize their processes, and stay ahead of the competition in today’s fast-paced industrial landscape.

How to Choose the Right Reliable 100 Mesh Filter Screen for Domestic Use

When it comes to choosing the right filter screen for domestic use, reliability is key. A 100 mesh filter screen is a popular choice for both industrial and domestic applications due to its ability to effectively filter out particles and debris. However, with so many options available on the market, it can be overwhelming to choose the right one for your specific needs.

One of the first things to consider when selecting a 100 mesh filter screen for domestic use is the material it is made from. Stainless steel is a common choice for filter screens due to its durability and resistance to corrosion. Additionally, stainless steel mesh screens are easy to clean and maintain, making them a practical option for domestic use.

Another important factor to consider is the size of the mesh openings. A 100 mesh screen has 100 openings per inch, which allows for the filtration of fine particles. This makes it ideal for applications where a high level of filtration is required, such as in water filtration systems or air conditioning units.

In addition to material and mesh size, it is also important to consider the size and shape of the filter screen. The screen should be sized to fit the specific application it will be used for, whether it is a small household appliance or a larger industrial system. Additionally, the shape of the screen should be chosen based on the flow rate and pressure requirements of the system.

When selecting a 100 mesh filter screen for domestic use, it is also important to consider the quality of the product. Look for screens that are manufactured by reputable companies with a track record of producing high-quality products. Additionally, consider reading reviews and testimonials from other customers to ensure that the filter screen will meet your expectations.

Finally, consider the cost of the filter screen. While it is important to invest in a high-quality product, it is also important to consider your budget. Compare prices from different manufacturers and suppliers to find a filter screen that offers the best value for your money.

In conclusion, choosing the right 100 mesh filter screen for domestic use requires careful consideration of material, mesh size, size and shape, quality, and cost. By taking the time to research and compare different options, you can find a reliable filter screen that will effectively meet your filtration needs. Whether you are looking to filter water, air, or other substances, a 100 mesh filter screen is a versatile and practical choice for domestic use.

Maintenance Tips for Ensuring Longevity of Reliable 100 Mesh Filter Screens

When it comes to maintaining the longevity of your reliable 100 mesh filter screens, there are a few key tips to keep in mind. These filter screens are essential for both industrial and domestic use, as they help to ensure that your equipment and appliances are running smoothly and efficiently. By following these maintenance tips, you can extend the life of your filter screens and avoid costly repairs or replacements.

One of the most important maintenance tips for reliable 100 mesh filter screens is to regularly clean and inspect them. Over time, dirt, debris, and other contaminants can build up on the screens, reducing their effectiveness and potentially causing damage to your equipment. By cleaning the screens on a regular basis, you can prevent these issues and ensure that your filter screens are working at their optimal level.

To clean your reliable 100 mesh filter screens, simply remove them from their housing and rinse them thoroughly with water. You can also use a mild detergent or cleaning solution to help remove any stubborn buildup. Once the screens are clean, be sure to inspect them for any signs of damage or wear. If you notice any tears, holes, or other issues, it may be time to replace the screens to prevent further damage to your equipment.

In addition to regular cleaning and inspection, it is also important to replace your reliable 100 mesh filter screens on a regular basis. Over time, the screens can become worn out or damaged, reducing their effectiveness and potentially causing issues with your equipment. By replacing the screens at the recommended intervals, you can ensure that your equipment is always protected and running smoothly.

When replacing your filter screens, be sure to choose screens that are compatible with your equipment and meet the same specifications as the original screens. This will help to ensure that your equipment continues to operate efficiently and effectively. Additionally, be sure to follow the manufacturer’s recommendations for replacing the screens to ensure that they are installed correctly and securely.

Another important maintenance tip for reliable 100 mesh filter screens is to monitor the pressure and flow rate of your equipment. If you notice a decrease in pressure or flow rate, it may be a sign that your filter screens are becoming clogged or worn out. By monitoring these factors regularly, you can catch any issues early on and take the necessary steps to address them before they cause damage to your equipment.

By following these maintenance tips, you can ensure that your reliable 100 mesh filter screens continue to protect your equipment and appliances for years to come. Regular cleaning, inspection, and replacement of the screens are essential for maintaining their longevity and effectiveness. By taking care of your filter screens, you can avoid costly repairs and replacements and keep your equipment running smoothly and efficiently.