Table of Contents

Benefits of Using nylon filter mesh in Food and Beverage Processing

Nylon filter mesh is a versatile material that finds applications across various industries, including food and beverage processing. Its unique properties make it an ideal choice for filtering and separating solids from liquids in a wide range of processes. In this article, we will explore the benefits of using nylon filter mesh in food and beverage processing and how it helps improve efficiency and quality in these industries.

One of the key advantages of nylon filter mesh is its durability and resistance to chemicals and abrasion. This makes it suitable for use in harsh environments where other materials may degrade or break down. In food and beverage processing, where filters are exposed to a variety of substances, including acids, alkalis, and oils, nylon filter mesh provides a reliable and long-lasting solution.

Another benefit of nylon filter mesh is its flexibility and ease of customization. It can be manufactured in a wide range of sizes and shapes to suit different filtration requirements. This versatility allows food and beverage manufacturers to use nylon filter mesh in various stages of their production processes, from initial filtration to final polishing.

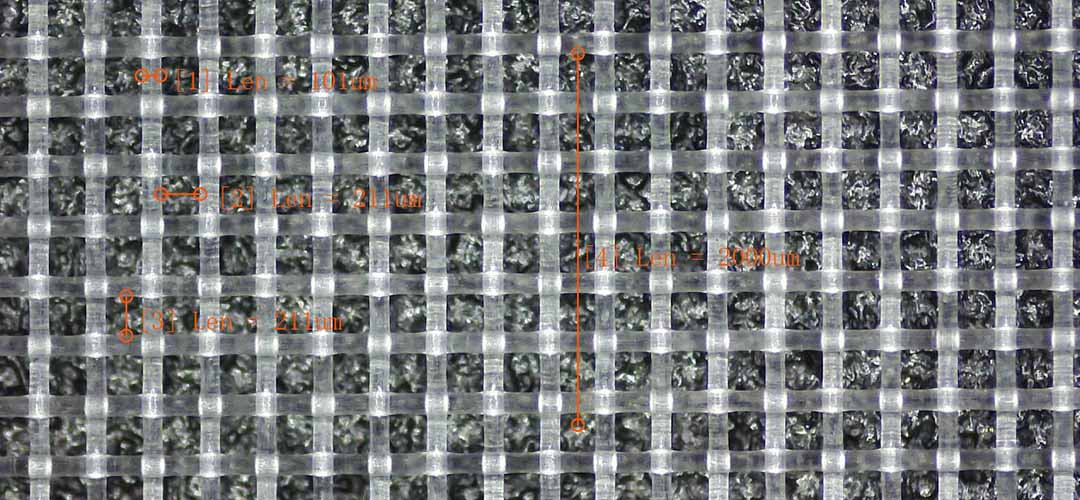

Nylon filter mesh also offers excellent filtration efficiency, thanks to its uniform pore size distribution and high flow rates. This ensures that particles of all sizes are captured effectively, resulting in a cleaner and clearer end product. In food and beverage processing, where product quality is paramount, nylon filter mesh helps maintain consistency and purity throughout the production process.

Furthermore, nylon filter mesh is easy to clean and maintain, reducing downtime and increasing productivity. Its smooth surface allows for quick and thorough cleaning, ensuring that filters can be reused multiple times without compromising performance. This not only saves time and money but also reduces waste and environmental impact.

In addition to these benefits, nylon filter mesh is also cost-effective compared to other filtration materials. Its long lifespan and low maintenance requirements make it a cost-efficient choice for food and beverage manufacturers looking to optimize their production processes. By investing in nylon filter mesh, companies can improve efficiency, reduce operating costs, and enhance product quality.

Overall, the real-world applications of nylon filter mesh in food and beverage processing are vast and varied. From initial filtration to final polishing, nylon filter mesh offers a reliable and efficient solution for separating solids from liquids and ensuring product quality. Its durability, flexibility, and filtration efficiency make it an indispensable tool for food and beverage manufacturers looking to streamline their processes and deliver high-quality products to consumers.

In conclusion, nylon filter mesh is a valuable asset for the food and beverage industry, offering a range of benefits that help improve efficiency and quality in production processes. Its durability, flexibility, and filtration efficiency make it an ideal choice for a wide range of applications, from initial filtration to final polishing. By investing in nylon filter mesh, food and beverage manufacturers can enhance their operations, reduce costs, and deliver superior products to consumers.

How Nylon Filter Mesh Improves Water Treatment Processes

Nylon filter mesh has emerged as a pivotal component in the water treatment industry, significantly enhancing the efficiency and effectiveness of various purification processes. As water scarcity and quality issues become increasingly pressing global concerns, the demand for reliable filtration solutions has surged. Nylon filter mesh, known for its durability, chemical resistance, and versatility, plays a crucial role in addressing these challenges.

One of the primary advantages of nylon filter mesh in water treatment is its ability to provide precise filtration. The mesh is available in a range of pore sizes, allowing for the removal of particulates, sediments, and contaminants from water sources. This capability is particularly beneficial in municipal water treatment facilities, where the need to ensure safe drinking water is paramount. By effectively filtering out larger particles and microorganisms, nylon mesh contributes to the production of clean, potable water, thereby safeguarding public health.

Moreover, the chemical resistance of nylon filter mesh makes it suitable for various water treatment applications, including those involving aggressive chemicals and varying pH levels. This resilience ensures that the mesh maintains its structural integrity and filtration efficiency over time, even in challenging environments. Consequently, water treatment plants can rely on nylon filter mesh for consistent performance, reducing the need for frequent replacements and minimizing operational downtime.

In addition to its physical properties, nylon filter mesh also supports advanced water treatment technologies, such as membrane filtration and reverse osmosis systems. These technologies are increasingly employed to achieve higher levels of purification, particularly in industrial applications where water quality standards are stringent. The integration of nylon filter mesh into these systems enhances their overall efficiency by acting as a pre-filter, capturing larger particles before they reach the more delicate membranes. This not only prolongs the lifespan of the membranes but also optimizes the overall filtration process, leading to cost savings and improved water quality.

Furthermore, the lightweight nature of nylon filter mesh facilitates easy handling and installation, making it an attractive option for water treatment facilities. Its flexibility allows for customization to fit various filtration systems, ensuring that operators can implement tailored solutions that meet specific needs. This adaptability is particularly valuable in regions where water sources may vary significantly in quality and composition, necessitating a dynamic approach to filtration.

The environmental benefits of using nylon filter mesh in water treatment processes cannot be overlooked. By improving the efficiency of filtration systems, nylon mesh contributes to reduced energy consumption and lower operational costs. Additionally, the effective removal of contaminants helps protect aquatic ecosystems, as treated water is less likely to introduce harmful substances into natural water bodies. This alignment with sustainability goals is increasingly important for industries and municipalities striving to minimize their environmental footprint.

In conclusion, the application of nylon filter mesh in water treatment processes represents a significant advancement in the quest for clean and safe water. Its ability to provide precise filtration, withstand harsh conditions, and enhance the performance of advanced treatment technologies underscores its value across various sectors. As the global demand for effective water treatment solutions continues to grow, nylon filter mesh will undoubtedly play a vital role in shaping the future of water purification, ensuring that communities have access to the essential resource of clean water.

Applications of Nylon Filter Mesh in Pharmaceutical Manufacturing

Nylon filter mesh is a versatile material that finds applications across various industries, including pharmaceutical manufacturing. The use of nylon filter mesh in this sector is crucial for ensuring the quality and purity of pharmaceutical products.

One of the primary applications of nylon filter mesh in pharmaceutical manufacturing is in the filtration of liquids. Nylon filter mesh is used to remove impurities, particles, and contaminants from liquids during the production process. This helps to ensure that the final pharmaceutical product is of high quality and meets regulatory standards.

Nylon filter mesh is also used in the filtration of gases in pharmaceutical manufacturing. Gases used in the production of pharmaceutical products need to be free of impurities and contaminants to prevent contamination of the final product. Nylon filter mesh helps to achieve this by effectively filtering out particles and impurities from gases.

Another important application of nylon filter mesh in pharmaceutical manufacturing is in the separation of solids from liquids. Nylon filter mesh is used in filtration systems to separate solid particles from liquid solutions, ensuring that only the desired components are retained in the final product. This is essential for maintaining the purity and quality of pharmaceutical products.

In addition to filtration, nylon filter mesh is also used in pharmaceutical manufacturing for the purification of solvents and reagents. Nylon filter mesh helps to remove impurities and contaminants from solvents and reagents, ensuring that they are of high purity and suitable for use in pharmaceutical production.

Nylon filter mesh is also used in the production of drug delivery systems in the pharmaceutical industry. Nylon filter mesh is used to create controlled-release systems that deliver drugs at a controlled rate over a specified period of time. This helps to improve the efficacy and safety of pharmaceutical products.

Overall, nylon filter mesh plays a crucial role in ensuring the quality, purity, and safety of pharmaceutical products. Its versatility and effectiveness make it an indispensable material in pharmaceutical manufacturing. By using nylon filter mesh in various applications, pharmaceutical companies can ensure that their products meet regulatory standards and are safe for consumption.

In conclusion, the real-world applications of nylon filter mesh in pharmaceutical manufacturing are diverse and essential for ensuring the quality and purity of pharmaceutical products. From filtration to purification and drug delivery systems, nylon filter mesh plays a vital role in the production of pharmaceuticals. Its versatility and effectiveness make it a valuable material for pharmaceutical companies looking to maintain high standards of quality and safety in their products.