Table of Contents

Benefits of Using Premium 5 micron stainless steel mesh Filters

Premium 5 micron stainless steel mesh filters offer a range of benefits that make them an essential choice for various filtration applications across industries. One of the primary advantages of these filters is their exceptional durability. Unlike traditional filters made from paper or plastic, stainless steel mesh filters are resistant to corrosion, high temperatures, and physical wear. This durability ensures a longer lifespan, reducing the need for frequent replacements and ultimately leading to cost savings for businesses. Furthermore, the robust nature of stainless steel allows these filters to maintain their structural integrity even under challenging conditions, making them ideal for demanding environments.

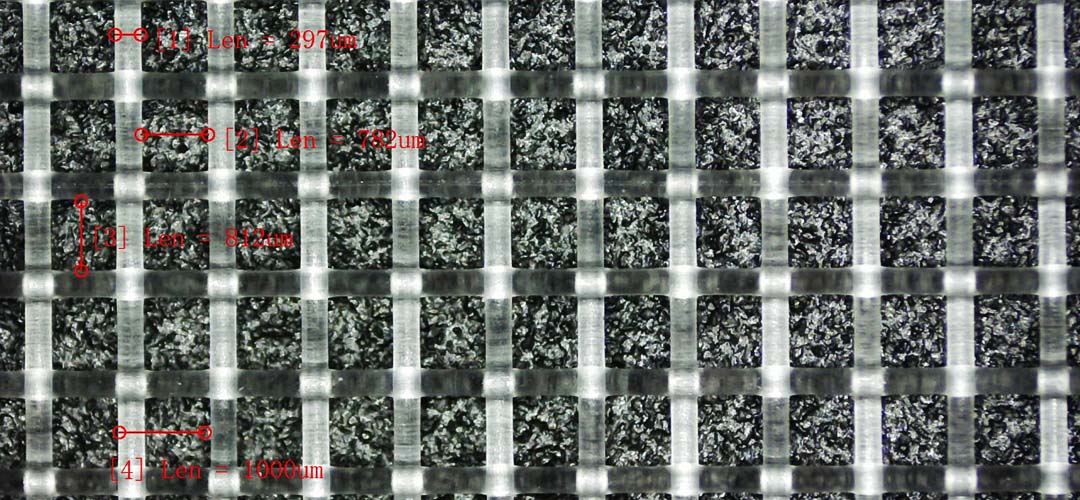

Another significant benefit of using premium 5 micron stainless steel mesh filters is their superior filtration capability. With a pore size of just 5 microns, these filters effectively capture a wide range of particles, including dirt, rust, and other contaminants. This level of filtration is crucial in industries such as food and beverage, pharmaceuticals, and water treatment, where maintaining high purity standards is essential. By removing unwanted particles, these filters help ensure the quality and safety of the final product, thereby enhancing customer satisfaction and compliance with regulatory standards.

In addition to their filtration efficiency, premium stainless steel mesh filters are also environmentally friendly. Unlike disposable filters that contribute to landfill waste, stainless steel filters are reusable and can be easily cleaned and sanitized. This reusability not only reduces waste but also minimizes the environmental impact associated with the production and disposal of traditional filters. Companies that prioritize sustainability can benefit from incorporating these filters into their operations, showcasing their commitment to eco-friendly practices.

Moreover, the versatility of 5 micron stainless steel mesh filters cannot be overlooked. They can be utilized in a variety of applications, from industrial processes to residential water filtration systems. This adaptability makes them a valuable asset for businesses looking to streamline their filtration solutions. Whether used in oil and gas, chemical processing, or even in home brewing, these filters provide reliable performance across different settings, making them a go-to choice for many industries.

The ease of maintenance associated with stainless steel mesh filters is another compelling reason to consider their use. Cleaning these filters is a straightforward process, often requiring only a simple rinse or soak in a cleaning solution. This ease of maintenance not only saves time but also ensures that the filters continue to perform at optimal levels. In contrast, traditional filters may require more complex replacement procedures, leading to downtime and increased operational costs.

Furthermore, the cost-effectiveness of premium 5 micron stainless steel mesh filters is noteworthy. While the initial investment may be higher than that of disposable filters, the long-term savings achieved through their durability, reusability, and reduced maintenance needs make them a wise financial choice. Businesses can allocate their resources more efficiently, knowing that they are investing in a product that will deliver consistent performance over time.

In conclusion, the benefits of using premium 5 micron stainless steel mesh filters are manifold. Their durability, superior filtration capabilities, environmental friendliness, versatility, ease of maintenance, and cost-effectiveness make them an ideal choice for a wide range of applications. As industries continue to prioritize quality and sustainability, these filters stand out as a reliable solution that meets both operational needs and environmental responsibilities. By choosing premium stainless steel mesh filters, businesses can enhance their filtration processes while contributing to a more sustainable future.

How to Properly Maintain and Clean Stainless Steel Mesh Filters

Maintaining and cleaning stainless steel mesh filters is essential for ensuring their longevity and optimal performance. These filters, known for their durability and efficiency, require a systematic approach to upkeep. Regular maintenance not only enhances their filtration capabilities but also prevents potential issues that could arise from neglect. To begin with, it is crucial to establish a routine cleaning schedule based on the specific application and the environment in which the filters operate. For instance, filters used in high-dust or high-contaminant areas may require more frequent cleaning compared to those in cleaner environments.

When it comes to the actual cleaning process, the first step is to remove the filter from its housing. This should be done carefully to avoid damaging any components. Once removed, a visual inspection is necessary to identify any signs of wear or damage. If the filter appears to be in good condition, the next step involves rinsing it with water to remove loose debris. It is advisable to use a gentle stream of water, as high pressure can deform the mesh or push contaminants deeper into the filter material.

After rinsing, a more thorough cleaning can be performed using a mild detergent. It is important to choose a detergent that is compatible with stainless steel to avoid any adverse reactions. Applying the detergent with a soft brush or cloth allows for effective removal of stubborn particles without scratching the surface. Care should be taken to ensure that all detergent residues are rinsed away, as any remaining chemicals can compromise the filter’s performance.

In addition to regular cleaning, periodic deep cleaning is recommended, especially for filters that handle oily or sticky substances. This process may involve soaking the filter in a solution of warm water and detergent for a specified period, followed by thorough rinsing. For particularly challenging residues, ultrasonic cleaning can be employed. This method uses high-frequency sound waves to agitate a cleaning solution, effectively dislodging contaminants from the filter mesh.

Once the cleaning process is complete, it is essential to dry the filter properly before reinstallation. Air drying is often the best method, as it prevents the introduction of lint or other particles that could occur with cloth drying. Ensuring that the filter is completely dry helps to prevent rust or corrosion, which can significantly reduce its lifespan.

Furthermore, regular inspections should be part of the maintenance routine. Checking for signs of wear, such as fraying or holes in the mesh, is vital. If any damage is detected, it is crucial to replace the filter promptly to maintain system efficiency. Additionally, keeping a log of cleaning and inspection activities can help track the filter’s condition over time, allowing for better planning of maintenance schedules.

In conclusion, the proper maintenance and cleaning of stainless steel mesh filters are fundamental to their performance and durability. By establishing a routine cleaning schedule, employing appropriate cleaning methods, and conducting regular inspections, users can ensure that their filters operate at peak efficiency. This proactive approach not only extends the life of the filters but also enhances the overall effectiveness of the filtration system, ultimately leading to improved operational outcomes. Investing time and resources into the maintenance of these filters is a strategic decision that pays dividends in reliability and performance.

Comparing Stainless Steel Mesh Filters to Other Types of Filtration Systems

When it comes to filtration systems, the choice of material and design plays a crucial role in determining the effectiveness and efficiency of the process. Among the various options available, stainless steel mesh filters, particularly those with a premium 5-micron rating, stand out for their superior performance compared to other types of filtration systems. This comparison highlights the advantages of stainless steel mesh filters, particularly in terms of durability, maintenance, and filtration efficiency.

One of the primary benefits of stainless steel mesh filters is their exceptional durability. Unlike traditional filters made from paper or plastic, stainless steel is resistant to corrosion, high temperatures, and physical wear. This resilience ensures that stainless steel filters maintain their structural integrity over time, even in demanding environments. As a result, businesses can rely on these filters for long-term use without the need for frequent replacements, which can be both costly and time-consuming. In contrast, other filtration systems often require regular maintenance and replacement, leading to increased operational costs and downtime.

Moreover, the 5-micron rating of premium stainless steel mesh filters allows for a high level of filtration efficiency. This fine mesh captures particles as small as 5 microns, effectively removing contaminants from liquids and gases. This level of precision is particularly beneficial in industries such as food and beverage, pharmaceuticals, and chemicals, where the purity of the final product is paramount. While other filtration systems may offer varying levels of filtration, they often struggle to achieve the same level of effectiveness without compromising flow rates. In many cases, businesses find themselves needing multiple filtration stages to achieve the desired purity, which can complicate the filtration process and increase costs.

In addition to their filtration capabilities, stainless steel mesh filters are also easier to clean and maintain. Many systems require the replacement of filter media, which can generate waste and contribute to environmental concerns. In contrast, stainless steel filters can be easily cleaned and reused, making them a more sustainable option. This not only reduces waste but also minimizes the need for additional resources, such as replacement filters and disposal services. As businesses increasingly prioritize sustainability, the ability to maintain a clean and efficient filtration system without generating excess waste becomes a significant advantage.

Furthermore, the versatility of stainless steel mesh filters cannot be overlooked. They can be customized to fit various applications and can be used in a wide range of industries. Whether it’s for water treatment, oil filtration, or air purification, these filters can be tailored to meet specific requirements. This adaptability is often lacking in other filtration systems, which may be designed for specific applications and may not perform well outside of those parameters.

In conclusion, when comparing stainless steel mesh filters to other types of filtration systems, it becomes evident that the premium 5-micron stainless steel mesh filters offer numerous advantages. Their durability ensures long-term use, while their high filtration efficiency meets the stringent requirements of various industries. Additionally, the ease of maintenance and sustainability of stainless steel filters further solidify their position as a superior choice. As businesses continue to seek reliable and efficient filtration solutions, the benefits of premium stainless steel mesh filters will undoubtedly make them a preferred option in the market.