Table of Contents

Benefits of Using Premium 100 micron nylon mesh for filtration

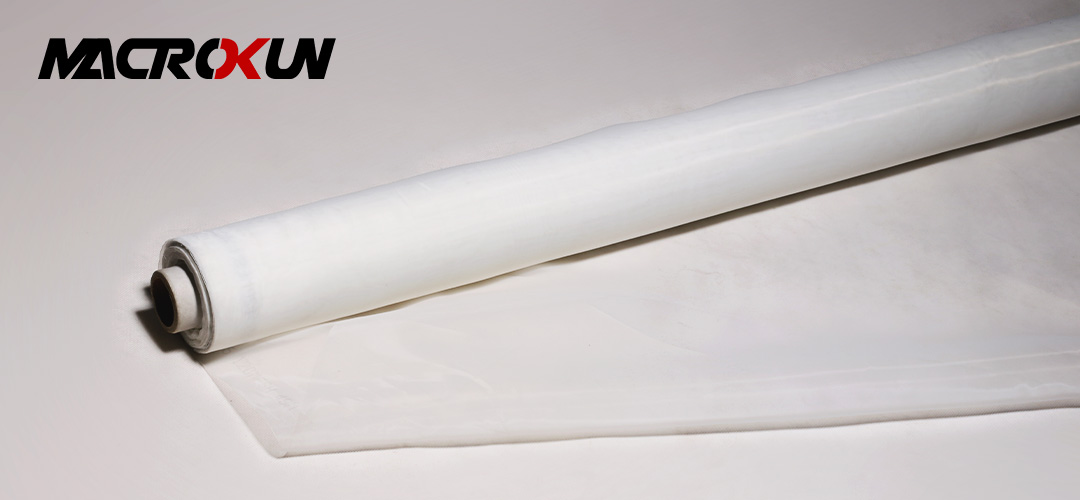

When it comes to filtration, using the right materials is crucial to achieving reliable results. One material that has gained popularity in the filtration industry is premium 100 micron nylon mesh. This type of mesh offers a range of benefits that make it a top choice for many filtration applications.

One of the key benefits of using premium 100 micron nylon mesh is its durability. Nylon is known for its strength and resilience, making it ideal for use in filtration systems that are subject to high pressures and temperatures. This durability ensures that the mesh will not break or tear easily, allowing it to maintain its integrity over time.

In addition to its durability, premium 100 micron nylon mesh also offers excellent filtration efficiency. The 100 micron pore size is ideal for capturing small particles and contaminants, ensuring that the filtrate is clean and free of impurities. This level of filtration efficiency is essential in industries where product purity is critical, such as pharmaceuticals, food and beverage, and electronics manufacturing.

Another benefit of using premium 100 micron nylon mesh is its versatility. Nylon mesh can be easily customized to meet specific filtration requirements, making it suitable for a wide range of applications. Whether you need a mesh that is chemically resistant, heat resistant, or anti-static, nylon can be modified to meet your needs.

Furthermore, premium 100 micron nylon mesh is easy to clean and maintain, reducing downtime and increasing productivity. Unlike some other filtration materials, nylon mesh can be cleaned with a simple rinse or wash, making it a cost-effective option for businesses looking to minimize maintenance costs.

In addition to its durability, efficiency, versatility, and ease of maintenance, premium 100 micron nylon mesh is also environmentally friendly. Nylon is a recyclable material, making it a sustainable choice for businesses looking to reduce their environmental impact. By choosing nylon mesh for filtration, businesses can not only improve their filtration results but also contribute to a more sustainable future.

Overall, the benefits of using premium 100 micron nylon mesh for filtration are clear. Its durability, efficiency, versatility, ease of maintenance, and environmental friendliness make it a top choice for businesses looking to achieve reliable filtration results. Whether you are in the pharmaceutical, food and beverage, electronics, or any other industry that requires high-quality filtration, premium 100 micron nylon mesh is a material worth considering.

How to Choose the Right Size and Type of Nylon Mesh for Filtration Needs

When it comes to filtration, choosing the right size and type of nylon mesh is crucial for achieving reliable results. Nylon mesh is a popular choice for filtration due to its durability, flexibility, and chemical resistance. With a wide range of mesh sizes available, it can be overwhelming to determine which one is best suited for your specific filtration needs. In this article, we will discuss the importance of selecting the correct mesh size and type for optimal filtration performance.

One of the key factors to consider when choosing a nylon mesh is the mesh size, which is typically measured in microns. The mesh size refers to the number of openings per linear inch in the mesh material. A higher mesh size indicates a finer mesh with smaller openings, while a lower mesh size indicates a coarser mesh with larger openings. The choice of mesh size will depend on the size of the particles you are trying to filter out.

For applications that require fine filtration, such as removing small particles or debris from liquids, a higher mesh size is recommended. A 100-micron nylon mesh, for example, is ideal for capturing particles as small as 100 microns in size. This fine mesh is commonly used in industries such as pharmaceuticals, food and beverage, and electronics, where precision filtration is essential for product quality and safety.

On the other hand, if you are filtering larger particles or debris, a lower mesh size may be more suitable. A 200-micron nylon mesh, for instance, is better suited for applications that require a coarser filtration, such as removing sediment from water or separating larger particles from a mixture. By selecting the appropriate mesh size for your filtration needs, you can ensure efficient and effective removal of contaminants from your process fluids.

In addition to mesh size, the type of nylon mesh is also an important consideration when choosing a filtration material. Nylon mesh is available in different types, such as monofilament and multifilament, each with its own unique properties and advantages. Monofilament nylon mesh is made from a single continuous strand of nylon, resulting in a smooth surface and uniform opening size. This type of mesh is ideal for applications that require high flow rates and minimal particle entrapment.

On the other hand, multifilament nylon mesh is made from multiple strands of nylon twisted together, creating a more porous and flexible material. This type of mesh is suitable for applications that require higher strength and durability, such as industrial filtration or wastewater treatment. By selecting the right type of nylon mesh for your specific filtration needs, you can ensure optimal performance and longevity of your filtration system.

In conclusion, choosing the right size and type of nylon mesh is essential for achieving reliable filtration results. By considering factors such as mesh size and type, you can select a nylon mesh that is tailored to your specific filtration requirements. Whether you need fine filtration for small particles or coarse filtration for larger contaminants, there is a premium 100-micron nylon mesh available to meet your needs. Invest in quality nylon mesh for your filtration system and experience the benefits of efficient and effective particle removal.

Tips for Maintaining and Cleaning Premium 100 Micron Nylon Mesh for Longevity and Efficiency

Maintaining and cleaning premium 100 micron nylon mesh is essential for ensuring its longevity and efficiency in filtration applications. This type of mesh is widely recognized for its reliability and effectiveness in various industries, including food processing, pharmaceuticals, and water treatment. To maximize the performance of your nylon mesh, it is crucial to adopt a systematic approach to maintenance and cleaning.

First and foremost, regular inspection of the mesh is vital. By routinely checking for signs of wear, tear, or clogging, you can identify potential issues before they escalate. This proactive measure not only extends the lifespan of the mesh but also ensures that it continues to deliver optimal filtration results. During inspections, pay close attention to the mesh’s integrity, looking for any fraying or damage that could compromise its functionality. If any defects are found, it is advisable to replace the mesh promptly to avoid contamination or inefficiency in your filtration process.

When it comes to cleaning, the method you choose can significantly impact the mesh’s performance. For most applications, a gentle cleaning process is recommended. Begin by rinsing the mesh with clean water to remove any loose particles or debris. This initial step is crucial, as it prevents larger particles from becoming embedded in the mesh during the cleaning process. Following the rinse, a mild detergent can be used to further cleanse the mesh. It is important to select a detergent that is compatible with nylon to avoid damaging the material. After applying the detergent, gently scrub the mesh with a soft brush or cloth, ensuring that you do not apply excessive pressure, which could lead to deformation.

Once the cleaning is complete, thorough rinsing is essential. Residual detergent can affect the mesh’s filtration capabilities, so it is imperative to ensure that all cleaning agents are completely washed away. After rinsing, allow the mesh to air dry in a clean environment. Avoid using heat sources, as high temperatures can compromise the structural integrity of the nylon. Proper drying not only prevents the growth of mold or bacteria but also prepares the mesh for its next use.

In addition to regular cleaning, it is beneficial to establish a maintenance schedule based on the frequency of use and the specific application of the mesh. For instance, if the mesh is used in a high-volume filtration process, more frequent inspections and cleanings may be necessary. Conversely, if the mesh is used less often, a less rigorous schedule may suffice. By tailoring your maintenance routine to the specific demands of your application, you can ensure that the mesh remains in peak condition.

Furthermore, storing the nylon mesh correctly when not in use is another critical aspect of maintenance. It should be kept in a cool, dry place, away from direct sunlight and harsh chemicals that could degrade the material. Proper storage not only protects the mesh from environmental factors but also helps maintain its shape and functionality over time.

In conclusion, the longevity and efficiency of premium 100 micron nylon mesh depend significantly on regular maintenance and proper cleaning techniques. By implementing a routine that includes inspections, gentle cleaning, thorough rinsing, and appropriate storage, you can ensure that your nylon mesh continues to perform reliably in its filtration role. This commitment to care not only enhances the mesh’s lifespan but also contributes to the overall effectiveness of your filtration processes, ultimately leading to better results in your operations.