Table of Contents

Benefits of Using Precise 40 Micron Filter Mesh for Medium-Sized Particle Removal

When it comes to filtration systems, precision is key. Ensuring that the right size mesh is used for the particles being filtered is essential for optimal performance. One common size used for medium-sized particle removal is 40 microns. This precise 40 micron filter mesh offers a range of benefits for businesses and industries looking to improve their filtration processes.

One of the main benefits of using a 40 micron filter mesh is its ability to effectively remove medium-sized particles from a variety of liquids and gases. This level of precision ensures that only particles of a certain size are able to pass through the mesh, resulting in cleaner and purer end products. Whether filtering water, chemicals, or other substances, a 40 micron filter mesh can help improve the quality of the final product.

In addition to its filtration capabilities, a 40 micron filter mesh also offers a high level of durability and longevity. Made from high-quality materials, such as stainless steel or nylon, these meshes are designed to withstand harsh conditions and heavy use. This means that businesses can rely on their 40 micron filter mesh to perform consistently and effectively over time, reducing the need for frequent replacements and maintenance.

Another benefit of using a 40 micron filter mesh is its versatility. These meshes can be used in a wide range of industries and applications, from food and beverage production to pharmaceuticals and petrochemicals. Whether filtering out contaminants in a manufacturing process or ensuring the purity of a final product, a 40 micron filter mesh can be customized to meet the specific needs of each industry.

Furthermore, a 40 micron filter mesh is easy to install and maintain, making it a cost-effective solution for businesses looking to improve their filtration processes. With proper care and cleaning, these meshes can last for years, providing a reliable and efficient filtration solution for medium-sized particle removal.

In conclusion, the benefits of using a precise 40 micron filter mesh for medium-sized particle removal are clear. From its ability to effectively remove particles of a certain size to its durability and versatility, a 40 micron filter mesh offers a range of advantages for businesses and industries looking to improve their filtration processes. By investing in a high-quality 40 micron filter mesh, businesses can ensure cleaner and purer end products, reduce maintenance costs, and improve overall efficiency.

How to Choose the Right Precise 40 Micron Filter Mesh for Your Application

When it comes to choosing the right filter mesh for your application, precision is key. A 40 micron filter mesh is ideal for medium-sized particle removal, providing a balance between filtration efficiency and flow rate. However, not all 40 micron filter meshes are created equal. To ensure optimal performance, it is important to select a precise filter mesh that meets the specific requirements of your application.

One of the most important factors to consider when choosing a 40 micron filter mesh is the material. Stainless steel is a popular choice for filter mesh due to its durability and resistance to corrosion. Additionally, stainless steel filter mesh is easy to clean and maintain, making it ideal for applications that require frequent filter changes.

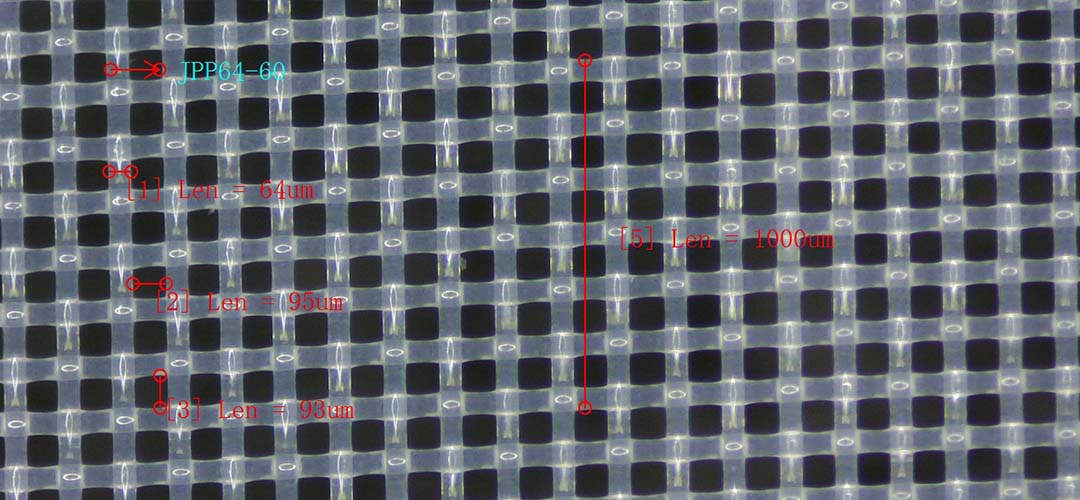

Another important consideration is the weave pattern of the filter mesh. The weave pattern determines the size and shape of the openings in the mesh, which in turn affects the filtration efficiency. For medium-sized particle removal, a plain weave pattern is often recommended. This weave pattern provides a uniform filtration surface, ensuring consistent performance across the entire filter mesh.

In addition to material and weave pattern, the size of the filter mesh openings is also crucial. A 40 micron filter mesh should have openings that are precisely 40 microns in size. This level of precision is essential for effectively capturing medium-sized particles while allowing smaller particles to pass through. To ensure accuracy, it is recommended to choose a filter mesh from a reputable manufacturer that adheres to strict quality control standards.

When selecting a 40 micron filter mesh, it is important to consider the flow rate of your application. A filter mesh with smaller openings will provide higher filtration efficiency but may also restrict flow. Conversely, a filter mesh with larger openings will allow for greater flow but may sacrifice filtration efficiency. By choosing a precise 40 micron filter mesh that strikes the right balance between filtration efficiency and flow rate, you can ensure optimal performance for your application.

In conclusion, choosing the right precise 40 micron filter mesh for medium-sized particle removal requires careful consideration of material, weave pattern, opening size, and flow rate. By selecting a high-quality filter mesh that meets the specific requirements of your application, you can achieve optimal filtration performance and prolong the life of your equipment. Remember to consult with a knowledgeable supplier to ensure that you are getting the right filter mesh for your needs. With the right filter mesh in place, you can confidently tackle medium-sized particle removal with precision and efficiency.

Case Studies: Successful Applications of Precise 40 Micron Filter Mesh in Various Industries

In various industries, the need for precise filtration of medium-sized particles is crucial to ensure the quality and efficiency of processes. One of the most effective solutions for this requirement is the use of a 40-micron filter mesh. This type of mesh is designed to capture particles that are larger than 40 microns in size, providing a high level of filtration efficiency.

One successful application of the precise 40-micron filter mesh can be seen in the automotive industry. In automotive manufacturing plants, there is a need to filter out medium-sized particles such as metal shavings, dirt, and debris from the coolant and lubricants used in the production process. By using a 40-micron filter mesh, these particles can be effectively removed, ensuring that the coolant and lubricants remain clean and free from contaminants. This, in turn, helps to prolong the life of machinery and equipment, reducing maintenance costs and downtime.

Another industry where the precise 40-micron filter mesh has proven to be highly effective is the food and beverage industry. In food processing plants, it is essential to maintain strict hygiene standards to ensure the safety and quality of products. By using a 40-micron filter mesh, food manufacturers can effectively remove medium-sized particles such as food debris, sediment, and other contaminants from liquids and ingredients. This helps to prevent contamination and spoilage, ensuring that the final products meet regulatory requirements and consumer expectations.

The pharmaceutical industry is another sector where the precise 40-micron filter mesh has been successfully implemented. In pharmaceutical manufacturing facilities, there is a need to filter out medium-sized particles such as powders, granules, and other impurities from liquids and gases used in the production process. By using a 40-micron filter mesh, pharmaceutical companies can ensure that their products are free from contaminants, meeting the stringent quality standards set by regulatory authorities.

In the mining and mineral processing industry, the precise 40-micron filter mesh has also found widespread use. In mining operations, there is a need to filter out medium-sized particles such as sand, gravel, and other solids from water and slurry streams. By using a 40-micron filter mesh, mining companies can effectively remove these particles, ensuring that the water and slurry are clean and free from impurities. This helps to protect equipment and machinery from damage, as well as to comply with environmental regulations regarding water discharge.

Overall, the precise 40-micron filter mesh has proven to be a valuable tool in various industries for the removal of medium-sized particles. Its high filtration efficiency and reliability make it an ideal choice for applications where precision and consistency are paramount. By implementing this type of filter mesh, businesses can improve the quality and efficiency of their processes, leading to cost savings, increased productivity, and enhanced product quality.