Table of Contents

Applications of nylon mesh in Industrial Filtration

Nylon mesh has become a popular choice for filter sieves in industrial filtration applications due to its durability and precision. This versatile material offers a wide range of benefits that make it ideal for use in a variety of industries, from food and beverage to pharmaceuticals and chemicals.

One of the key advantages of nylon mesh is its durability. Unlike other materials, such as stainless steel or polyester, nylon mesh is resistant to corrosion and abrasion, making it ideal for use in harsh industrial environments. This durability ensures that the filter sieve will last longer and require less maintenance, saving time and money in the long run.

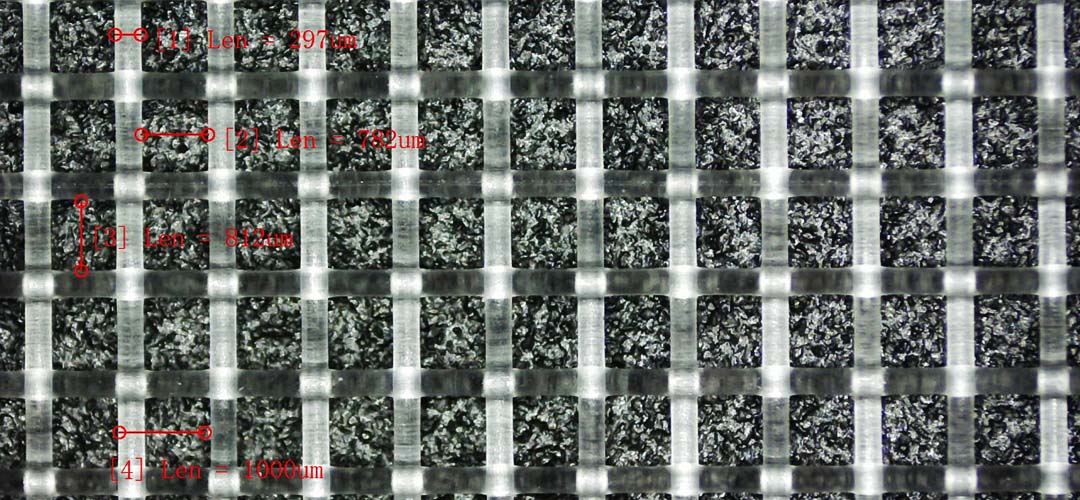

In addition to its durability, nylon mesh also offers precision in filtration. The fine mesh size of nylon allows for the removal of even the smallest particles from a liquid or gas stream, ensuring that the final product is of the highest quality. This precision is essential in industries where product purity is paramount, such as pharmaceuticals and electronics manufacturing.

Another benefit of nylon mesh is its versatility. Nylon mesh can be easily customized to meet the specific needs of a filtration application, whether that means adjusting the mesh size, thickness, or weave pattern. This flexibility makes nylon mesh an ideal choice for a wide range of industries and applications.

Nylon mesh is also easy to clean and maintain, further adding to its appeal in industrial filtration applications. Unlike other materials that may require special cleaning procedures or chemicals, nylon mesh can be easily cleaned with water and mild detergent, making it a cost-effective and low-maintenance option for filter sieves.

Overall, nylon mesh offers a winning combination of durability, precision, versatility, and ease of maintenance that make it an ideal choice for industrial filtration applications. Whether filtering liquids, gases, or solids, nylon mesh can provide the reliable performance and consistent results that industries demand.

In conclusion, nylon mesh is a valuable tool in industrial filtration, offering a range of benefits that make it an ideal choice for filter sieves. Its durability, precision, versatility, and ease of maintenance set nylon mesh apart from other materials, making it a popular choice in industries where product purity and quality are essential. With its proven track record in a variety of applications, nylon mesh continues to be a top choice for businesses looking to improve their filtration processes and achieve superior results.

Advantages of Using nylon mesh for filter sieves

Nylon mesh has become a popular choice for filter sieves in various industries due to its durability and precision in filtration. The advantages of using nylon mesh for filter sieves are numerous, making it a preferred option for many businesses looking to improve their filtration processes.

One of the key advantages of nylon mesh is its durability. Nylon is a strong and resilient material that can withstand high temperatures and harsh chemicals, making it ideal for use in demanding filtration applications. This durability ensures that the nylon mesh will not break or tear easily, providing a long-lasting solution for filtration needs.

In addition to its durability, nylon mesh also offers excellent precision in filtration. The fine mesh size of nylon allows for the efficient removal of particles and impurities from liquids and gases, ensuring a clean and pure end product. This precision is crucial in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest contaminants can have a significant impact on product quality.

Furthermore, nylon mesh is easy to clean and maintain, making it a cost-effective option for businesses. The smooth surface of nylon mesh prevents particles from becoming trapped in the mesh, allowing for quick and efficient cleaning. This ease of maintenance helps to reduce downtime and increase productivity, making nylon mesh a practical choice for businesses looking to streamline their filtration processes.

Another advantage of using nylon mesh for filter sieves is its versatility. Nylon mesh is available in a wide range of mesh sizes and configurations, allowing businesses to choose the right option for their specific filtration needs. Whether filtering large particles or fine contaminants, there is a nylon mesh solution available to meet the requirements of any industry.

Additionally, nylon mesh is lightweight and flexible, making it easy to install and replace in filter sieves. This flexibility allows for quick and efficient changes to filtration systems, ensuring minimal disruption to production processes. Nylon mesh can also be easily cut to size, making it a customizable option for businesses with unique filtration requirements.

Overall, the advantages of using nylon mesh for filter sieves make it a superior choice for businesses looking to improve their filtration processes. From its durability and precision to its ease of maintenance and versatility, nylon mesh offers a range of benefits that can help businesses achieve optimal filtration results.

In conclusion, nylon mesh is a durable, precise, and cost-effective solution for filter sieves in various industries. Its versatility and ease of maintenance make it a practical choice for businesses looking to enhance their filtration processes. By choosing nylon mesh for filter sieves, businesses can ensure a clean and pure end product while maximizing efficiency and productivity.

Maintenance Tips for nylon mesh filter Sieves

Nylon mesh filter sieves are essential tools in various industries, providing a reliable solution for filtration needs. Their durability and precision make them a preferred choice for many applications, from food processing to pharmaceuticals. However, to ensure optimal performance and longevity, proper maintenance of these filter sieves is crucial. Regular maintenance not only extends the lifespan of the nylon mesh but also enhances its filtration efficiency, ensuring that the desired quality of the end product is consistently achieved.

One of the primary maintenance tips for nylon mesh filter sieves is to conduct routine inspections. Regularly examining the mesh for signs of wear, tear, or clogging can help identify potential issues before they escalate. During these inspections, it is essential to check for any physical damage, such as fraying or holes, which can compromise the filtration process. Additionally, observing the mesh for any buildup of particles or contaminants can provide insight into its current performance level. If any issues are detected, timely repairs or replacements should be made to maintain the integrity of the filtration system.

Cleaning is another critical aspect of maintaining nylon mesh filter sieves. Depending on the application and the materials being filtered, the frequency and method of cleaning may vary. It is advisable to follow the manufacturer’s recommendations regarding cleaning procedures. Generally, a gentle wash with warm water and a mild detergent is effective in removing debris without damaging the mesh. For more stubborn residues, soaking the sieve in a cleaning solution may be necessary. After cleaning, it is vital to thoroughly rinse the mesh to eliminate any soap residue, as this can affect the quality of the filtered product. Proper drying is equally important; air drying is often the best method, as it prevents any potential damage that may occur from high heat.

Storage practices also play a significant role in the maintenance of nylon mesh filter sieves. When not in use, these sieves should be stored in a clean, dry environment to prevent contamination and damage. It is advisable to avoid stacking heavy items on top of the sieves, as this can lead to deformation of the mesh. Instead, they should be stored flat or hung to maintain their shape and functionality. Additionally, covering the sieves with a protective cloth or plastic can shield them from dust and other environmental factors that may compromise their performance.

Furthermore, it is essential to be mindful of the operating conditions when using nylon mesh filter sieves. Extreme temperatures, harsh chemicals, or abrasive materials can significantly reduce the lifespan of the mesh. Therefore, understanding the limitations of the nylon material is crucial. When working with aggressive substances, consider using a mesh specifically designed to withstand such conditions. This proactive approach not only protects the filter sieves but also ensures that the filtration process remains efficient and effective.

In conclusion, maintaining nylon mesh filter sieves involves a combination of regular inspections, proper cleaning, careful storage, and awareness of operating conditions. By adhering to these maintenance tips, businesses can ensure that their filtration systems operate at peak performance, ultimately leading to higher quality products and increased operational efficiency. Investing time and resources into the upkeep of these essential tools is a strategic decision that pays dividends in the long run, reinforcing the importance of durability and precision in filtration processes.