Table of Contents

Benefits of Using nylon mesh 200 micron for Filtration

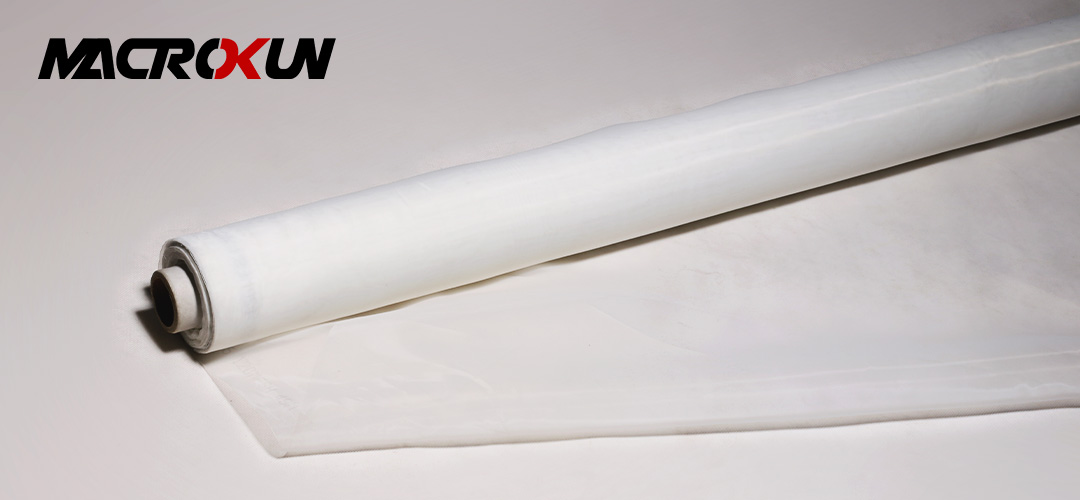

Nylon mesh 200 micron is a popular choice for filtration in various industries due to its reliable and consistent performance. This type of mesh is known for its durability, flexibility, and efficiency in capturing particles of a specific size. Whether used in water treatment, food processing, pharmaceuticals, or any other application requiring precise filtration, nylon mesh 200 micron has proven to be a trusted solution for achieving desired results.

One of the key benefits of using nylon mesh 200 micron is its ability to provide consistent filtration results. The uniformity of the mesh ensures that particles of the specified size are captured effectively, leading to a high level of filtration efficiency. This consistency is crucial in industries where product quality and safety are paramount, as any variation in filtration performance can have significant consequences.

In addition to its consistency, nylon mesh 200 micron is also known for its durability. The material is resistant to chemicals, abrasion, and high temperatures, making it suitable for a wide range of applications. This durability ensures that the mesh can withstand harsh operating conditions without compromising its filtration performance, resulting in long-lasting and reliable filtration solutions.

Furthermore, nylon mesh 200 micron offers flexibility in terms of customization. The mesh can be tailored to meet specific filtration requirements, such as particle size, flow rate, and operating conditions. This flexibility allows for the optimization of filtration processes, leading to improved efficiency and cost savings. Whether used for coarse or fine filtration, nylon mesh 200 micron can be customized to deliver the desired results consistently.

Another advantage of using nylon mesh 200 micron is its ease of maintenance. The material is easy to clean and maintain, reducing downtime and ensuring continuous operation. This ease of maintenance is particularly beneficial in industries where frequent filter replacement or cleaning is required, as it helps to minimize operational disruptions and maximize productivity.

Moreover, nylon mesh 200 micron is cost-effective compared to other filtration options. The material is affordable and readily available, making it a cost-efficient solution for businesses looking to optimize their filtration processes. By choosing nylon mesh 200 micron, companies can achieve reliable filtration results without breaking the bank, leading to long-term savings and improved profitability.

In conclusion, nylon mesh 200 micron is a trusted choice for consistent filtration results in various industries. Its durability, flexibility, efficiency, and cost-effectiveness make it an ideal solution for businesses looking to enhance their filtration processes. By choosing nylon mesh 200 micron, companies can achieve reliable and efficient filtration performance, leading to improved product quality, safety, and cost savings. Whether used in water treatment, food processing, pharmaceuticals, or any other application requiring precise filtration, nylon mesh 200 micron is a reliable and effective solution for achieving desired results consistently.

How Nylon Mesh 200 Micron Ensures Consistent Filtration Results

Nylon mesh 200 micron is a popular choice for filtration applications due to its consistent and reliable performance. This type of mesh is known for its durability, flexibility, and ability to capture particles of various sizes. Whether used in industrial, commercial, or residential settings, nylon mesh 200 micron is trusted to deliver consistent filtration results time and time again.

One of the key reasons why nylon mesh 200 micron is preferred for filtration is its uniform pore size. The 200 micron size is ideal for capturing particles that are larger than most other types of mesh, making it an effective choice for a wide range of applications. This consistency in pore size ensures that the mesh will perform consistently over time, providing reliable filtration results with each use.

In addition to its uniform pore size, nylon mesh 200 micron is also known for its high tensile strength. This means that the mesh is able to withstand high pressures and temperatures without breaking or tearing. This durability makes nylon mesh 200 micron a long-lasting and cost-effective option for filtration applications, as it can withstand the rigors of continuous use without needing frequent replacement.

Another benefit of nylon mesh 200 micron is its flexibility. The mesh can be easily cut to size and shaped to fit a variety of filtration systems, making it a versatile option for a wide range of applications. Whether used in liquid filtration, air filtration, or solid particle separation, nylon mesh 200 micron can be customized to meet the specific needs of any filtration system.

Furthermore, nylon mesh 200 micron is resistant to chemicals and corrosion, making it suitable for use in harsh environments where other types of mesh may degrade or break down over time. This resistance to chemicals and corrosion ensures that the mesh will maintain its integrity and filtration efficiency even in the most challenging conditions.

Overall, nylon mesh 200 micron is a trusted choice for consistent filtration results due to its uniform pore size, high tensile strength, flexibility, and resistance to chemicals and corrosion. Whether used in industrial, commercial, or residential settings, this type of mesh is known for its reliability and durability, making it a popular choice for a wide range of filtration applications.

In conclusion, nylon mesh 200 micron is a reliable and consistent option for filtration applications. Its uniform pore size, high tensile strength, flexibility, and resistance to chemicals and corrosion make it a versatile and durable choice for a wide range of filtration systems. Whether used in liquid filtration, air filtration, or solid particle separation, nylon mesh 200 micron is trusted to deliver consistent filtration results time and time again.

Applications of Nylon Mesh 200 Micron in Various Industries

Nylon mesh 200 micron is a versatile and reliable material that is widely used in various industries for filtration purposes. Its fine mesh size of 200 microns makes it ideal for capturing small particles and ensuring consistent filtration results. In this article, we will explore the applications of nylon mesh 200 micron in different industries and how it helps in achieving efficient filtration.

One of the key industries where nylon mesh 200 micron is commonly used is the food and beverage industry. In this industry, maintaining high levels of cleanliness and hygiene is crucial to ensure the safety of the products. Nylon mesh 200 micron is used in filtration systems to remove impurities, debris, and contaminants from liquids such as juices, oils, and syrups. Its fine mesh size allows for efficient filtration without compromising the quality of the final product.

Another industry where nylon mesh 200 micron is widely utilized is the pharmaceutical industry. In pharmaceutical manufacturing, the purity of the products is of utmost importance to ensure their effectiveness and safety for consumption. Nylon mesh 200 micron is used in filtration processes to remove particles, bacteria, and other impurities from liquids and gases. Its high filtration efficiency and durability make it an ideal choice for pharmaceutical companies looking to achieve consistent and reliable results.

The automotive industry is another sector where nylon mesh 200 micron finds extensive use. In automotive manufacturing, various fluids such as oils, coolants, and fuels need to be filtered to ensure the smooth operation of vehicles. Nylon mesh 200 micron is used in filtration systems to remove contaminants and debris from these fluids, thereby preventing damage to the engine and other components. Its high tensile strength and resistance to chemicals make it a preferred choice for automotive applications.

In the water treatment industry, nylon mesh 200 micron plays a crucial role in ensuring the quality of drinking water. Water treatment plants use nylon mesh 200 micron in filtration systems to remove suspended solids, bacteria, and other impurities from water sources. Its fine mesh size allows for effective filtration without clogging, ensuring that clean and safe drinking water is delivered to households and businesses.

The textile industry also benefits from the use of nylon mesh 200 micron in various processes. In textile manufacturing, dyes and chemicals are used to color and treat fabrics. Nylon mesh 200 micron is used in filtration systems to remove impurities and particles from these chemicals, ensuring that the final product meets quality standards. Its durability and resistance to high temperatures make it an ideal choice for textile applications.

Overall, nylon mesh 200 micron is a trusted material that delivers consistent filtration results across different industries. Its fine mesh size, high filtration efficiency, and durability make it a versatile solution for a wide range of applications. Whether it is in the food and beverage industry, pharmaceutical industry, automotive industry, water treatment industry, or textile industry, nylon mesh 200 micron plays a vital role in ensuring the quality and purity of products and processes. With its proven performance and reliability, nylon mesh 200 micron continues to be a preferred choice for filtration applications worldwide.