Table of Contents

Benefits of Using nylon mesh 200 micron for High Efficiency Filtration

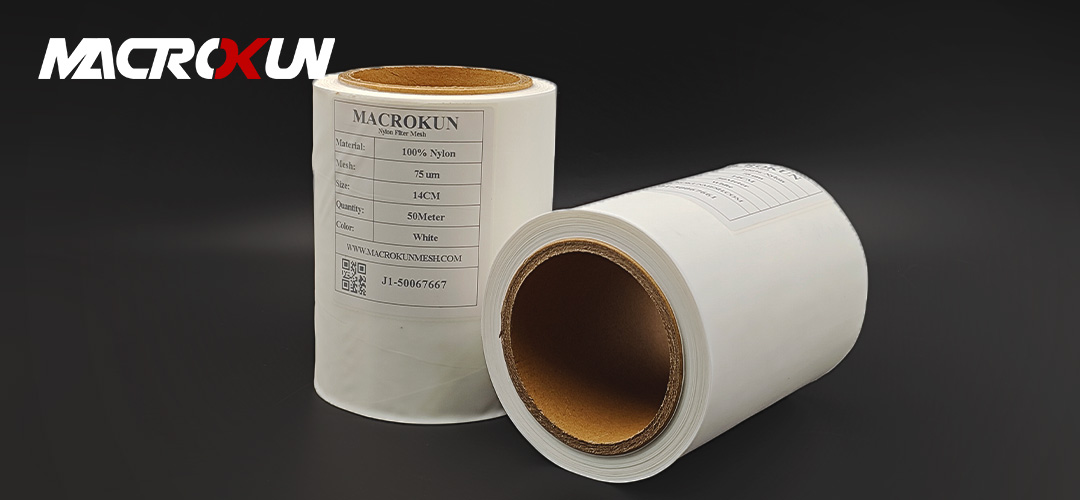

Nylon mesh 200 micron is a versatile and efficient material that is widely used in various industries for high-efficiency filtration. Its fine mesh size of 200 microns makes it ideal for capturing small particles and contaminants, ensuring superior results in filtration processes. There are several benefits to using nylon mesh 200 micron, including its durability, flexibility, and cost-effectiveness.

One of the key advantages of nylon mesh 200 micron is its durability. Nylon is a strong and resilient material that can withstand high temperatures and harsh chemicals, making it suitable for use in demanding filtration applications. The 200-micron mesh size provides an optimal balance between filtration efficiency and flow rate, ensuring that the mesh can effectively capture particles while allowing liquids or gases to pass through smoothly. This durability ensures that nylon mesh 200 micron can be used repeatedly without losing its effectiveness, making it a cost-effective choice for filtration systems.

In addition to its durability, nylon mesh 200 micron is also highly flexible, allowing it to conform to different shapes and sizes. This flexibility makes it easy to customize the mesh to fit specific filtration requirements, ensuring that it can be used in a wide range of applications. Whether filtering liquids, gases, or solids, nylon mesh 200 micron can be tailored to meet the unique needs of each filtration process, providing consistent and reliable results.

Furthermore, nylon mesh 200 micron is a cost-effective option for high-efficiency filtration. Its long-lasting durability means that it can be used multiple times before needing to be replaced, reducing maintenance costs and downtime. Additionally, the fine mesh size of 200 microns ensures that the mesh can effectively capture small particles and contaminants, reducing the risk of contamination and improving overall filtration efficiency. This cost-effectiveness makes nylon mesh 200 micron a practical choice for businesses looking to optimize their filtration processes while minimizing expenses.

Overall, nylon mesh 200 micron offers a range of benefits for high-efficiency filtration. Its durability, flexibility, and cost-effectiveness make it a versatile and reliable material for a wide range of applications. Whether filtering liquids, gases, or solids, nylon mesh 200 micron can provide superior results and consistent performance, helping businesses achieve their filtration goals efficiently and effectively.

In conclusion, nylon mesh 200 micron is a high-quality material that offers numerous benefits for high-efficiency filtration. Its durability, flexibility, and cost-effectiveness make it a practical choice for businesses looking to improve their filtration processes and achieve superior results. By utilizing nylon mesh 200 micron, businesses can enhance their filtration efficiency, reduce maintenance costs, and ensure consistent performance in their operations.

How Nylon Mesh 200 Micron Provides Superior Results in Various Applications

Nylon Mesh 200 Micron: High Efficiency, Superior Results

In today’s fast-paced business environment, efficiency and superior results are paramount. When it comes to filtration and separation applications, choosing the right mesh size is crucial. One option that stands out is the Nylon Mesh 200 Micron. This versatile and high-quality mesh offers numerous benefits that make it the preferred choice for a wide range of industries.

One of the key advantages of Nylon Mesh 200 Micron is its exceptional efficiency. With a mesh size of 200 microns, it provides a fine filtration capability that effectively removes unwanted particles from liquids and gases. This level of precision ensures that the desired end product meets the highest quality standards. Whether it’s in the pharmaceutical, food and beverage, or chemical industry, Nylon Mesh 200 Micron delivers consistent and reliable results.

Furthermore, Nylon Mesh 200 Micron offers superior durability and longevity. Made from high-quality nylon material, this mesh is resistant to wear and tear, ensuring a longer lifespan compared to other materials. This durability is particularly important in industries where the filtration process is continuous and demanding. With Nylon Mesh 200 Micron, businesses can reduce downtime and maintenance costs, ultimately improving overall productivity.

Another advantage of Nylon Mesh 200 Micron is its versatility. This mesh can be used in a wide range of applications, including but not limited to filtration, separation, and sieving. Its fine mesh size makes it ideal for removing small particles, such as dust, pollen, and debris, from liquids and gases. Additionally, Nylon Mesh 200 Micron can be customized to meet specific requirements, such as different shapes and sizes, making it suitable for various industries and processes.

Moreover, Nylon Mesh 200 Micron offers excellent chemical resistance. This property is crucial in industries where the filtration process involves corrosive substances or harsh chemicals. The nylon material used in this mesh is resistant to a wide range of chemicals, ensuring that the filtration process remains efficient and unaffected by chemical reactions. This resistance to chemicals also contributes to the longevity of the mesh, making it a cost-effective choice for businesses.

In addition to its efficiency and durability, Nylon Mesh 200 Micron is easy to clean and maintain. Its smooth surface allows for effortless cleaning, ensuring that the mesh remains free from clogs and blockages. This ease of maintenance is particularly beneficial in industries where frequent cleaning is required to maintain optimal performance. By choosing Nylon Mesh 200 Micron, businesses can save time and resources on maintenance, allowing them to focus on their core operations.

In conclusion, Nylon Mesh 200 Micron is a high-quality and versatile option for filtration and separation applications. Its fine mesh size, durability, versatility, chemical resistance, and ease of maintenance make it the preferred choice for various industries. By investing in Nylon Mesh 200 Micron, businesses can achieve high efficiency and superior results, ultimately enhancing their overall productivity and success.

Tips for Maintaining and Cleaning Nylon Mesh 200 Micron for Longevity and Optimal Performance

Nylon Mesh 200 Micron: High Efficiency, Superior Results

Tips for Maintaining and Cleaning Nylon Mesh 200 Micron for Longevity and Optimal Performance

When it comes to filtration systems, the nylon mesh 200 micron is a popular choice for many industries. Its high efficiency and superior results make it an ideal option for a wide range of applications. However, like any other equipment, proper maintenance and cleaning are essential to ensure its longevity and optimal performance. In this article, we will provide you with some valuable tips on how to maintain and clean your nylon mesh 200 micron.

First and foremost, it is crucial to establish a regular maintenance routine for your nylon mesh 200 micron. This includes inspecting the mesh for any signs of wear and tear, such as holes or fraying. By catching these issues early on, you can prevent further damage and avoid costly repairs or replacements. Additionally, make sure to clean the mesh regularly to remove any accumulated debris or contaminants that may hinder its performance.

When it comes to cleaning the nylon mesh 200 micron, there are a few important considerations to keep in mind. Firstly, always use a gentle cleaning solution that is specifically designed for nylon materials. Harsh chemicals or abrasive cleaners can damage the mesh and compromise its effectiveness. It is also advisable to use a soft brush or cloth to gently scrub the mesh, avoiding any excessive force that could cause damage.

Another crucial aspect of maintaining your nylon mesh 200 micron is proper storage. When not in use, make sure to store the mesh in a clean and dry environment. Moisture can lead to mold or mildew growth, which can deteriorate the mesh over time. Additionally, keep the mesh away from direct sunlight or extreme temperatures, as these can also cause damage.

In some cases, you may encounter stubborn stains or contaminants that are difficult to remove with regular cleaning methods. In such instances, it is recommended to consult the manufacturer’s guidelines or seek professional assistance. They can provide you with specialized cleaning techniques or recommend suitable cleaning products that are safe for your nylon mesh 200 micron.

Furthermore, it is essential to handle the nylon mesh 200 micron with care during installation and removal. Avoid pulling or stretching the mesh excessively, as this can weaken the fibers and reduce its lifespan. Instead, gently guide the mesh into place, ensuring a secure and snug fit. Similarly, when removing the mesh, do so with caution to prevent any accidental damage.

Lastly, regular inspections and performance evaluations are crucial to ensure that your nylon mesh 200 micron is functioning optimally. Monitor the filtration system’s efficiency and check for any signs of reduced performance, such as decreased flow rates or increased pressure differentials. By addressing any issues promptly, you can prevent further damage and maintain the longevity of your nylon mesh 200 micron.

In conclusion, proper maintenance and cleaning are vital for the longevity and optimal performance of your nylon mesh 200 micron. Establish a regular maintenance routine, inspect the mesh for any signs of wear and tear, and clean it regularly using gentle cleaning solutions and techniques. Store the mesh in a clean and dry environment, handle it with care during installation and removal, and seek professional assistance for stubborn stains or contaminants. By following these tips, you can ensure that your nylon mesh 200 micron continues to deliver high efficiency and superior results for your filtration needs.