Table of Contents

Understanding nylon filter mesh: Composition and Properties

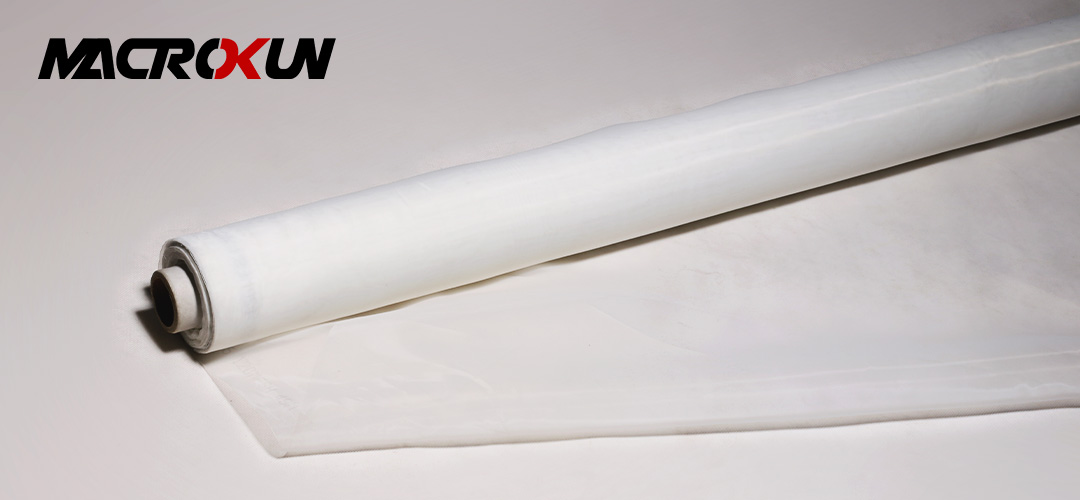

Nylon filter mesh is a critical component in many filtration processes, providing a reliable and efficient way to separate particles from liquids or gases. Understanding the composition and properties of nylon filter mesh is essential for ensuring its effectiveness in various applications.

Nylon filter mesh is made from synthetic polymer fibers known as polyamides, which are woven together to create a mesh structure. This composition gives nylon filter mesh its strength and durability, making it ideal for use in demanding filtration environments. The flexibility of nylon fibers allows for the creation of mesh with different pore sizes, making it suitable for filtering a wide range of particle sizes.

One of the key properties of nylon filter mesh is its resistance to chemicals and abrasion. This makes it a versatile choice for filtration applications where exposure to harsh chemicals or abrasive materials is common. Nylon filter mesh is also resistant to high temperatures, making it suitable for use in processes that involve heat.

Another important property of nylon filter mesh is its ability to maintain its shape and integrity under pressure. This ensures that the mesh retains its filtration efficiency even when subjected to high flow rates or differential pressures. The uniformity of the mesh structure also helps to prevent particle bypass, ensuring that all particles are captured effectively.

Nylon filter mesh is available in a range of pore sizes, from fine to coarse, allowing for precise control over the filtration process. Fine mesh is typically used for capturing small particles, while coarse mesh is used for larger particles. The choice of pore size depends on the specific requirements of the filtration application, such as the size of particles to be filtered and the desired flow rate.

In addition to its physical properties, nylon filter mesh is also easy to clean and maintain, making it a cost-effective choice for filtration systems. The smooth surface of nylon fibers prevents particles from becoming trapped in the mesh, allowing for easy cleaning with water or a mild detergent. This helps to prolong the life of the filter mesh and ensure consistent filtration performance over time.

Overall, nylon filter mesh plays a crucial role in many industrial and commercial filtration processes, providing a reliable and efficient way to separate particles from liquids or gases. Its composition and properties make it a versatile choice for a wide range of applications, from water treatment to chemical processing. Understanding the unique characteristics of nylon filter mesh is essential for selecting the right mesh for a specific filtration task and ensuring optimal performance.

Applications of Nylon Filter Mesh in Various Industries

Nylon filter mesh is a versatile material that plays a crucial role in filtration processes across various industries. Its unique properties make it an ideal choice for applications where fine filtration is required. From food and beverage production to pharmaceuticals and water treatment, nylon filter mesh is used in a wide range of industries to ensure the purity and quality of products.

One of the key advantages of nylon filter mesh is its durability. Made from synthetic fibers, nylon filter mesh is strong and resistant to wear and tear, making it suitable for high-pressure filtration applications. Its flexibility also allows it to conform to different shapes and sizes, making it a versatile option for a variety of filtration needs.

In the food and beverage industry, nylon filter mesh is commonly used to remove impurities and contaminants from liquids and solids. Whether it’s filtering out particles in wine production or removing sediment in brewing processes, nylon filter mesh helps ensure the quality and safety of the final product. Its fine mesh size allows for precise filtration, ensuring that only the desired particles pass through.

In the pharmaceutical industry, nylon filter mesh is used in the production of medications and medical devices. Its high chemical resistance makes it suitable for filtering out impurities and ensuring the purity of pharmaceutical products. From filtering out bacteria and viruses to removing particulates from solutions, nylon filter mesh plays a critical role in maintaining the quality and efficacy of pharmaceutical products.

In the water treatment industry, nylon filter mesh is used to remove contaminants and impurities from water sources. Whether it’s filtering out sediment in municipal water treatment plants or removing microorganisms in industrial water filtration systems, nylon filter mesh helps ensure the safety and cleanliness of water for various applications. Its high flow rate and efficiency make it an effective option for water filtration processes.

In the automotive industry, nylon filter mesh is used in oil and fuel filtration systems to remove particles and debris that can damage engines and reduce performance. Its high temperature resistance and chemical compatibility make it an ideal choice for filtering out contaminants in automotive fluids. From oil filters to fuel filters, nylon filter mesh helps protect engines and ensure optimal performance.

Overall, nylon filter mesh is a versatile material that plays a crucial role in filtration processes across various industries. Its durability, flexibility, and efficiency make it an ideal choice for applications where fine filtration is required. Whether it’s in food and beverage production, pharmaceuticals, water treatment, or automotive applications, nylon filter mesh helps ensure the purity and quality of products. Its unique properties make it a valuable tool for maintaining the safety and efficiency of filtration processes in a wide range of industries.

Benefits of Using Nylon Filter Mesh for Effective Filtration

Nylon filter mesh is a versatile and widely used material in the field of filtration. It is made from synthetic nylon fibers that are woven together to create a mesh-like structure. This material is known for its durability, flexibility, and resistance to chemicals and abrasion, making it an ideal choice for a variety of filtration applications.

One of the key benefits of using nylon filter mesh is its ability to effectively remove impurities from liquids and gases. The fine mesh structure of nylon allows for the filtration of particles as small as a few microns, ensuring that the filtered substance is free from contaminants. This makes nylon filter mesh an essential component in industries such as pharmaceuticals, food and beverage, and water treatment, where purity and cleanliness are of utmost importance.

Another advantage of nylon filter mesh is its high flow rate. The open weave design of the mesh allows for a smooth and efficient flow of the filtered substance, minimizing pressure drop and ensuring optimal filtration performance. This is particularly beneficial in applications where a high flow rate is required, such as in industrial processes or wastewater treatment.

In addition to its filtration capabilities, nylon filter mesh is also known for its longevity and resistance to wear and tear. The synthetic nylon fibers are highly durable and can withstand harsh operating conditions, making them a cost-effective choice for long-term filtration solutions. This durability also means that nylon filter mesh requires minimal maintenance, saving time and resources in the long run.

Furthermore, nylon filter mesh is easy to clean and sterilize, making it a hygienic choice for applications where cleanliness is essential. The smooth surface of nylon fibers prevents the buildup of bacteria and other microorganisms, ensuring that the filtered substance remains pure and uncontaminated. This makes nylon filter mesh an ideal choice for industries such as pharmaceuticals and food processing, where strict hygiene standards must be met.

Overall, the benefits of using nylon filter mesh for effective filtration are clear. Its durability, high flow rate, and resistance to chemicals make it a versatile and reliable choice for a wide range of applications. Whether you are filtering liquids or gases, removing impurities or contaminants, or ensuring the purity of your product, nylon filter mesh is a valuable tool that can help you achieve optimal filtration performance.

In conclusion, nylon filter mesh is a crucial component in the field of filtration, offering a range of benefits that make it an ideal choice for various industries. Its durability, high flow rate, and resistance to chemicals and abrasion make it a versatile and reliable material for effective filtration. Whether you are looking to remove impurities, ensure purity, or optimize filtration performance, nylon filter mesh is a valuable tool that can help you achieve your goals.