Table of Contents

Benefits of Using Nylon Cloth for Filtration in Industrial Applications

Nylon cloth is a versatile material that has been widely used in various industrial applications, including filtration. Its unique properties make it an ideal choice for filtering out impurities and contaminants from liquids and gases. In this article, we will explore the benefits of using nylon cloth for filtration in industrial settings.

One of the key advantages of nylon cloth is its durability. Nylon is a strong and resilient material that can withstand high temperatures and harsh chemicals, making it suitable for use in demanding industrial environments. This durability ensures that the nylon cloth will not break or tear easily, providing long-lasting filtration performance.

In addition to its durability, nylon cloth is also known for its excellent filtration efficiency. The fine mesh structure of nylon allows it to effectively capture even the smallest particles, ensuring that the filtered liquid or gas is free from impurities. This high filtration efficiency is crucial in industries where the purity of the final product is essential, such as pharmaceuticals, food and beverage, and electronics manufacturing.

Furthermore, nylon cloth is easy to clean and maintain, making it a cost-effective filtration solution for industrial applications. Unlike disposable filters that need to be replaced frequently, nylon cloth can be cleaned and reused multiple times, reducing the overall cost of filtration. This not only saves money but also reduces waste, making nylon cloth a more sustainable option for industrial filtration.

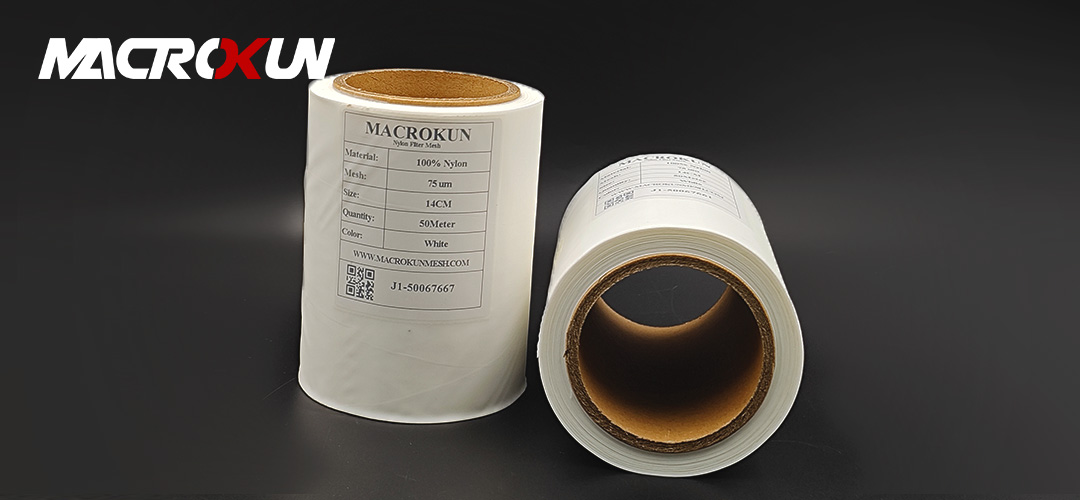

Another benefit of using nylon cloth for filtration is its versatility. Nylon cloth can be customized to meet specific filtration requirements, such as different mesh sizes and thicknesses. This flexibility allows for the filtration of a wide range of liquids and gases, making nylon cloth suitable for various industrial processes.

Moreover, nylon cloth is resistant to mold and mildew, making it ideal for applications where cleanliness is crucial. The non-porous surface of nylon prevents the growth of bacteria and fungi, ensuring that the filtered product remains uncontaminated. This is particularly important in industries such as pharmaceuticals and food processing, where hygiene standards are strict.

In conclusion, nylon cloth is a reliable and efficient filtration material that offers numerous benefits for industrial applications. Its durability, filtration efficiency, cost-effectiveness, versatility, and resistance to mold and mildew make it an ideal choice for industries that require high-quality filtration. Whether filtering liquids or gases, nylon cloth can provide the performance and reliability needed to meet the demands of modern industrial processes. Consider using nylon cloth for filtration in your industrial applications to experience the many benefits it has to offer.

How Nylon Cloth Filters Improve Efficiency and Performance in Various Industries

Nylon cloth filters have become an essential component in various industries due to their reliability and efficiency in improving performance. These filters are made from high-quality nylon material that is known for its durability and strength, making it ideal for use in demanding industrial applications. From food and beverage processing to pharmaceutical manufacturing, nylon cloth filters have proven to be a reliable solution for improving efficiency and ensuring the quality of the final product.

One of the key benefits of using nylon cloth filters is their ability to effectively remove impurities and contaminants from liquids and gases. The fine mesh of the nylon cloth allows for efficient filtration, ensuring that only clean and pure substances pass through. This is crucial in industries such as food and beverage processing, where the quality of the final product is of utmost importance. By using nylon cloth filters, manufacturers can ensure that their products meet the highest standards of purity and safety.

In addition to their filtration capabilities, nylon cloth filters are also known for their durability and longevity. Unlike other types of filters that may need frequent replacement, nylon cloth filters can withstand harsh conditions and continue to perform effectively over an extended period of time. This not only reduces maintenance costs but also ensures uninterrupted production processes, leading to increased efficiency and productivity.

Furthermore, nylon cloth filters are versatile and can be customized to meet the specific needs of different industries. Whether it is a fine mesh for removing small particles or a larger mesh for capturing larger contaminants, nylon cloth filters can be tailored to suit the requirements of any application. This flexibility makes them a popular choice among manufacturers looking for a reliable and cost-effective filtration solution.

Another advantage of using nylon cloth filters is their ease of installation and maintenance. These filters are lightweight and easy to handle, making them simple to install and replace when necessary. Additionally, nylon cloth filters can be easily cleaned and reused, further reducing operational costs and ensuring consistent performance.

In conclusion, nylon cloth filters are a reliable and efficient solution for improving efficiency and performance in various industries. Their ability to effectively remove impurities, durability, versatility, and ease of installation make them an ideal choice for manufacturers looking to enhance the quality of their products and streamline their production processes. Whether it is in food and beverage processing, pharmaceutical manufacturing, or any other industry, nylon cloth filters have proven to be a valuable asset in ensuring the success and competitiveness of businesses.

The Versatility of Nylon Cloth Filters for Different Filtration Requirements in Industrial Settings

Nylon cloth filters have become a staple in various industrial settings due to their versatility and reliability in meeting different filtration requirements. From separating solids from liquids to capturing fine particles, nylon cloth filters have proven to be an essential tool for maintaining the efficiency and quality of industrial processes.

One of the key advantages of nylon cloth filters is their ability to effectively trap particles of various sizes. Whether it’s removing large debris or capturing microscopic contaminants, nylon cloth filters can be tailored to meet specific filtration needs. This flexibility makes them ideal for a wide range of industries, from food and beverage production to pharmaceutical manufacturing.

In the food and beverage industry, nylon cloth filters are commonly used to remove impurities and ensure product quality. Whether it’s filtering out sediment in wine production or removing particles in fruit juice processing, nylon cloth filters play a crucial role in maintaining the purity and clarity of the final product. Their durability and resistance to chemicals make them a reliable choice for handling a variety of substances without compromising filtration efficiency.

In the pharmaceutical industry, where precision and purity are paramount, nylon cloth filters are essential for ensuring the quality of medications and medical devices. From filtering out contaminants in drug manufacturing to sterilizing equipment, nylon cloth filters provide a reliable barrier against impurities that could compromise product safety. Their high filtration efficiency and ability to withstand sterilization processes make them an indispensable tool for maintaining strict quality standards in pharmaceutical production.

Nylon cloth filters are also widely used in the automotive and aerospace industries for various applications, such as filtering hydraulic fluids, removing contaminants from fuel systems, and capturing particles in air filtration systems. Their durability and resistance to high temperatures and pressure make them well-suited for demanding industrial environments where reliability is crucial.

In addition to their filtration capabilities, nylon cloth filters are also easy to clean and maintain, making them a cost-effective solution for long-term use. Their reusable nature reduces waste and minimizes the need for frequent replacements, saving time and resources in the long run. This sustainability factor makes nylon cloth filters an environmentally friendly choice for industries looking to reduce their carbon footprint and operating costs.

Overall, nylon cloth filters have proven to be a reliable and versatile solution for meeting different filtration requirements in industrial settings. Their ability to trap particles of various sizes, withstand harsh conditions, and provide cost-effective filtration solutions make them an essential tool for maintaining the efficiency and quality of industrial processes. Whether it’s removing impurities in food and beverage production, ensuring product purity in pharmaceutical manufacturing, or meeting stringent quality standards in automotive and aerospace industries, nylon cloth filters are a trusted choice for all industrial filtration needs.