Table of Contents

Understanding the Importance of Micron Filter Mesh Sizes in Filtration Systems

Micron filter mesh sizes play a crucial role in the performance of filtration systems. These sizes are carefully tailored to ensure optimal filtration efficiency and effectiveness. Understanding the importance of micron filter mesh sizes is essential for businesses and industries that rely on filtration systems to maintain the quality of their products and processes.

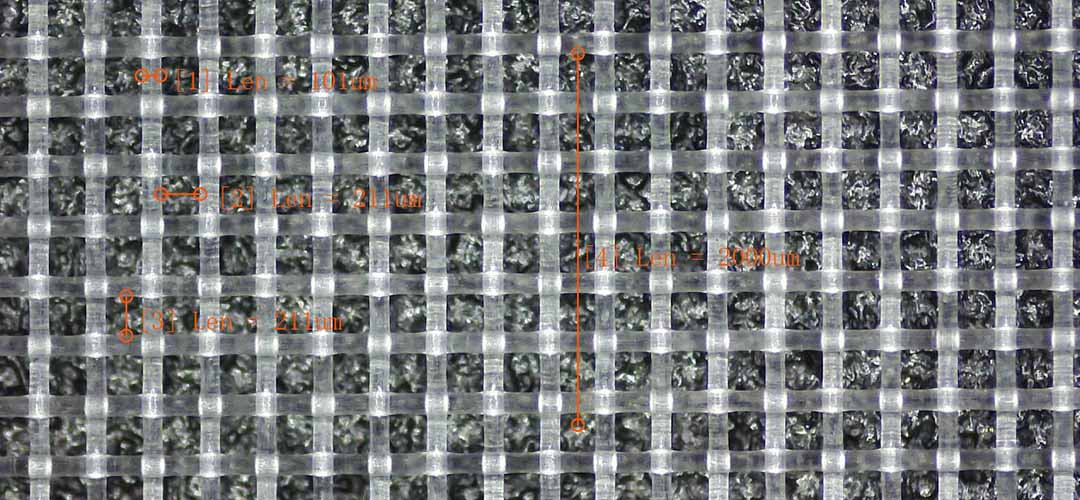

The term “micron” refers to a unit of measurement that is equal to one-millionth of a meter. In the context of filtration, micron filter mesh sizes refer to the size of the openings in the filter mesh. The smaller the micron size, the finer the filtration, as smaller particles are captured by the mesh. This is important in industries such as pharmaceuticals, food and beverage, and water treatment, where even the smallest contaminants can have a significant impact on product quality and safety.

Choosing the right micron filter mesh size is crucial for achieving the desired level of filtration. If the mesh size is too large, particles may pass through the filter, compromising the quality of the end product. On the other hand, if the mesh size is too small, the flow rate of the filtration system may be reduced, leading to inefficiencies and increased operating costs. It is therefore important to carefully consider the specific requirements of the application when selecting a micron filter mesh size.

In many industries, the use of multiple layers of filter mesh with different micron sizes is common practice. This allows for the removal of a wide range of particle sizes, ensuring thorough filtration and optimal performance. By using a combination of filter mesh sizes, businesses can customize their filtration systems to meet their specific needs and achieve the desired level of filtration efficiency.

The performance of a filtration system is also influenced by factors such as the material of the filter mesh and the design of the filter housing. High-quality materials such as stainless steel or nylon are commonly used for filter mesh, as they offer durability and resistance to corrosion. The design of the filter housing is also important, as it must be able to withstand the pressure and flow rate of the filtration system without compromising the integrity of the filter mesh.

In addition to selecting the right micron filter mesh size, businesses should also consider factors such as maintenance and cleaning procedures. Regular maintenance is essential for ensuring the longevity and effectiveness of the filtration system. This may involve replacing worn-out filter mesh or cleaning the filter housing to remove any buildup of contaminants. By following a regular maintenance schedule, businesses can prolong the life of their filtration system and maintain optimal performance.

In conclusion, micron filter mesh sizes are a critical component of filtration systems in various industries. By understanding the importance of micron filter mesh sizes and selecting the right size for their specific needs, businesses can achieve optimal filtration performance and ensure the quality and safety of their products and processes. With careful consideration of factors such as material, design, and maintenance, businesses can customize their filtration systems to meet their unique requirements and achieve maximum efficiency.

How to Select the Right Micron Filter Mesh Size for Your Specific Filtration Needs

Micron filter mesh sizes play a crucial role in determining the effectiveness of a filtration system. The size of the mesh directly impacts the level of filtration achieved, as it determines the size of particles that can pass through the filter. Selecting the right micron filter mesh size is essential for achieving optimal filtration performance in various industries, including pharmaceuticals, food and beverage, and water treatment.

When choosing a micron filter mesh size, it is important to consider the specific requirements of the application. Different industries have different filtration needs, and selecting the right mesh size is crucial for achieving the desired level of filtration. For example, in the pharmaceutical industry, where the filtration of fine particles is critical, a smaller micron filter mesh size may be required. On the other hand, in the food and beverage industry, where larger particles need to be filtered out, a larger micron filter mesh size may be more suitable.

One of the key factors to consider when selecting a micron filter mesh size is the size of the particles that need to be filtered. The mesh size of a filter is measured in microns, with smaller micron sizes indicating a finer mesh that can capture smaller particles. For example, a filter with a micron size of 5 will be able to capture particles as small as 5 microns, while a filter with a micron size of 100 will only be able to capture particles as small as 100 microns.

In addition to the size of the particles, the flow rate of the filtration system should also be taken into consideration when selecting a micron filter mesh size. A smaller micron filter mesh size will result in a higher level of filtration, but it may also restrict the flow rate of the system. On the other hand, a larger micron filter mesh size will allow for a higher flow rate, but it may not provide the same level of filtration as a smaller mesh size.

It is important to strike a balance between filtration efficiency and flow rate when selecting a micron filter mesh size. This can be achieved by conducting thorough testing and analysis to determine the optimal mesh size for the specific filtration needs of the application. By selecting the right micron filter mesh size, businesses can ensure that their filtration systems operate at peak performance, providing clean and safe products to consumers.

In conclusion, selecting the right micron filter mesh size is essential for achieving optimal filtration performance in various industries. By considering factors such as the size of the particles to be filtered and the flow rate of the system, businesses can determine the most suitable mesh size for their specific filtration needs. Conducting thorough testing and analysis will help ensure that the chosen mesh size provides the desired level of filtration efficiency while maintaining an acceptable flow rate. By investing in the right micron filter mesh size, businesses can enhance the quality of their products and maintain high standards of cleanliness and safety.

The Impact of Micron Filter Mesh Sizes on Filtration Performance and Efficiency

Micron filter mesh sizes play a crucial role in determining the filtration performance and efficiency of a filtration system. The size of the mesh openings directly impacts the ability of the filter to capture particles of a certain size, making it a critical factor in achieving optimal filtration results.

When it comes to micron filter mesh sizes, one size does not fit all. Different applications require different mesh sizes to effectively filter out contaminants and impurities. The size of the particles that need to be filtered will determine the appropriate micron filter mesh size to use. For example, a filtration system designed to remove large particles will require a larger mesh size, while a system targeting smaller particles will need a finer mesh size.

Choosing the right micron filter mesh size is essential for achieving the desired level of filtration performance. Using a mesh size that is too large will allow particles to pass through the filter, reducing its effectiveness. On the other hand, using a mesh size that is too small can lead to clogging and decreased flow rates, compromising the efficiency of the filtration system.

In addition to particle size, the material of the filter mesh also plays a role in determining filtration performance. Different materials have different properties that can affect the filtration process. For example, stainless steel mesh is known for its durability and resistance to corrosion, making it ideal for applications where the filter will be exposed to harsh conditions. On the other hand, nylon mesh is lightweight and easy to clean, making it suitable for applications where frequent maintenance is required.

The design of the filter mesh also influences filtration performance. The shape and arrangement of the mesh openings can impact the flow of fluid through the filter, as well as the ability of the filter to capture particles. A well-designed filter mesh will have a uniform structure that allows for efficient filtration without impeding flow rates.

In order to achieve optimal filtration performance, it is important to select a micron filter mesh size that is tailored to the specific requirements of the application. This may involve conducting tests to determine the size of particles that need to be filtered, as well as considering factors such as flow rates and pressure requirements. By choosing the right mesh size, material, and design, it is possible to maximize the efficiency of the filtration system and ensure that it delivers the desired level of performance.

In conclusion, micron filter mesh sizes are a critical factor in determining the filtration performance and efficiency of a filtration system. By selecting the right mesh size, material, and design, it is possible to achieve optimal filtration results and ensure that the system operates effectively. Taking the time to carefully consider these factors will help to maximize the performance of the filtration system and ensure that it meets the specific requirements of the application.