Table of Contents

Benefits of Using Micron Filter Mesh in Various Industries

Micron filter mesh is a versatile and cost-effective solution for a wide range of industries. From food and beverage production to pharmaceuticals and water treatment, micron filter mesh offers numerous benefits that can improve efficiency and quality control. In this article, we will explore the advantages of using micron filter mesh in various industries and provide a price guide to help you find affordable solutions for every budget.

One of the key benefits of using micron filter mesh is its ability to effectively remove impurities and contaminants from liquids and gases. With micron filter mesh, particles as small as 1 micron can be captured, ensuring that the final product meets the highest quality standards. This is particularly important in industries such as food and beverage production, where even the smallest impurities can affect the taste and safety of the product.

In addition to improving product quality, micron filter mesh can also help companies save money by reducing waste and increasing efficiency. By removing impurities at the source, companies can minimize the need for costly rework and ensure that their production processes run smoothly. This can result in significant cost savings over time, making micron filter mesh a smart investment for businesses of all sizes.

Another advantage of using micron filter mesh is its versatility. Micron filter mesh is available in a wide range of materials, including stainless steel, nylon, and polyester, making it suitable for a variety of applications. Whether you need to filter water, chemicals, or pharmaceuticals, there is a micron filter mesh solution that can meet your specific requirements.

When it comes to pricing, micron filter mesh is an affordable option for businesses of all sizes. Prices can vary depending on the material, size, and micron rating of the mesh, but there are options available to suit every budget. For example, a basic stainless steel micron filter mesh with a micron rating of 100 can cost as little as $10 per square foot, making it a cost-effective solution for small businesses and startups.

For companies with larger budgets, there are also high-end options available, such as custom-made micron filter mesh with specialized coatings and finishes. While these options may be more expensive, they offer additional benefits such as increased durability and longevity, making them a worthwhile investment for companies that require high-performance filtration solutions.

In conclusion, micron filter mesh offers numerous benefits for businesses in a wide range of industries. From improving product quality to reducing waste and increasing efficiency, micron filter mesh is a cost-effective solution that can help companies achieve their production goals. With a variety of options available at different price points, there is a micron filter mesh solution to suit every budget. Whether you are a small startup or a large corporation, investing in micron filter mesh can help you achieve your filtration goals and improve your bottom line.

Factors Affecting Micron Filter Mesh Prices

When it comes to purchasing micron filter mesh, there are several factors that can affect the price you pay. Understanding these factors can help you make an informed decision and find the best solution for your budget. In this article, we will explore the key factors that influence micron filter mesh prices and provide a price guide to help you find affordable solutions for every budget.

One of the most significant factors that can impact the price of micron filter mesh is the material used in its construction. Micron filter mesh can be made from a variety of materials, including stainless steel, nylon, and polyester. Each material has its own unique properties and benefits, which can affect the overall cost of the mesh. Stainless steel mesh, for example, is known for its durability and resistance to corrosion, making it a popular choice for industrial applications. However, stainless steel mesh tends to be more expensive than nylon or polyester mesh due to the higher cost of the raw materials.

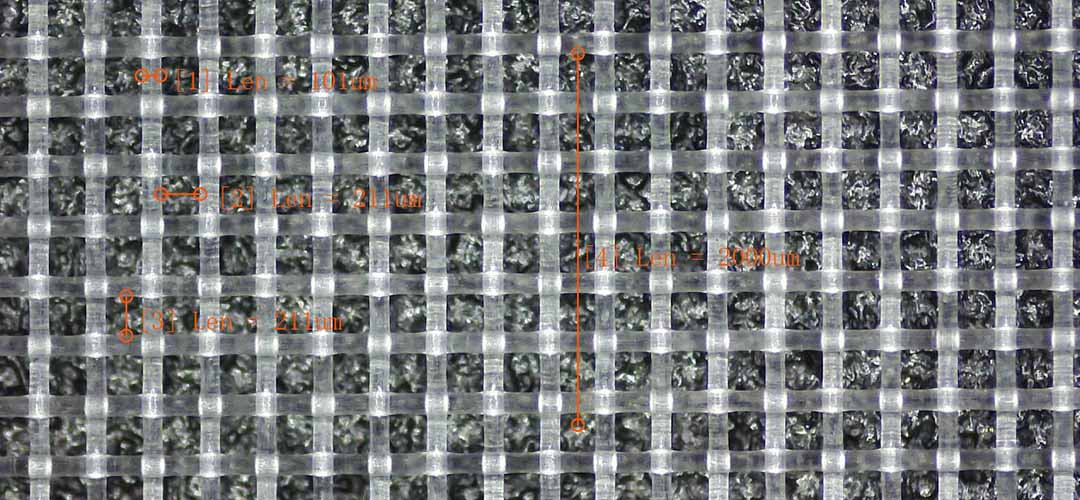

Another factor that can influence the price of micron filter mesh is the mesh size or micron rating. Micron filter mesh is available in a range of sizes, from coarse to fine, with smaller micron ratings indicating a finer mesh. Finer mesh sizes are typically more expensive than coarser mesh sizes due to the increased precision and tighter tolerances required in their production. If you require a high level of filtration efficiency, you may need to invest in a finer mesh size, which can impact the overall cost of the filter.

The type of weave used in the construction of the micron filter mesh can also affect its price. There are several different weave patterns available, including plain weave, twill weave, and Dutch weave, each offering unique benefits in terms of strength, filtration efficiency, and flow rate. Dutch weave mesh, for example, is known for its high filtration accuracy and excellent flow characteristics, but it tends to be more expensive than plain or twill weave mesh due to the complexity of its construction.

In addition to material, mesh size, and weave type, the quantity of micron filter mesh you purchase can also impact the price you pay. Bulk orders typically receive discounts or wholesale pricing, making it more cost-effective to purchase larger quantities of mesh at once. If you have a large filtration project or need to replace multiple filters, buying in bulk can help you save money in the long run.

When comparing prices for micron filter mesh, it’s essential to consider the overall quality and performance of the mesh. While price is an important factor, it should not be the only consideration when choosing a filter mesh. Investing in a high-quality mesh that meets your filtration requirements can help you avoid costly replacements and downtime in the future.

In conclusion, there are several factors that can affect the price of micron filter mesh, including material, mesh size, weave type, and quantity. By understanding these factors and comparing prices from different suppliers, you can find affordable solutions for every budget. Whether you need a durable stainless steel mesh for industrial applications or a fine Dutch weave mesh for precise filtration, there are options available to suit your needs. With the right information and guidance, you can make an informed decision and find the best micron filter mesh for your specific requirements.

Comparing different micron filter mesh Options for Cost-Effective Solutions

When it comes to choosing the right micron filter mesh for your filtration needs, cost is often a significant factor to consider. With a wide range of options available on the market, finding an affordable solution that meets your requirements can be a daunting task. In this article, we will compare different micron filter mesh options to help you find a cost-effective solution that fits within your budget.

One of the most popular and cost-effective options for micron filter mesh is nylon. nylon mesh is known for its durability and resistance to chemicals, making it an ideal choice for a wide range of filtration applications. Additionally, nylon mesh is available in a variety of micron sizes, allowing you to choose the right mesh for your specific needs.

Another affordable option for micron filter mesh is polyester. Polyester mesh is lightweight and easy to clean, making it a popular choice for applications where frequent cleaning is required. Additionally, polyester mesh is resistant to mildew and abrasion, ensuring long-lasting performance.

For those looking for a more budget-friendly option, polypropylene mesh is an excellent choice. Polypropylene mesh is lightweight, flexible, and resistant to chemicals, making it an ideal choice for applications where cost is a primary concern. While polypropylene mesh may not be as durable as nylon or polyester, it is still a cost-effective solution for many filtration needs.

In addition to the material of the mesh, the micron size also plays a significant role in determining the cost of the filter. Generally, the smaller the micron size, the higher the cost of the mesh. However, it is essential to choose the right micron size for your specific application to ensure optimal filtration performance.

When comparing different micron filter mesh options, it is essential to consider not only the upfront cost but also the long-term cost of maintenance and replacement. While some mesh materials may be more affordable initially, they may require more frequent replacement, leading to higher long-term costs. Therefore, it is crucial to weigh the upfront cost against the long-term cost to find the most cost-effective solution for your filtration needs.

In conclusion, there are several cost-effective options available for micron filter mesh, ranging from nylon and polyester to polypropylene. By considering factors such as material, micron size, and long-term maintenance costs, you can find an affordable solution that meets your filtration requirements without breaking the bank. Whether you are looking for a durable and chemical-resistant mesh or a budget-friendly option, there is a micron filter mesh available for every budget.