Table of Contents

Benefits of Using stainless steel micron filter Mesh Materials

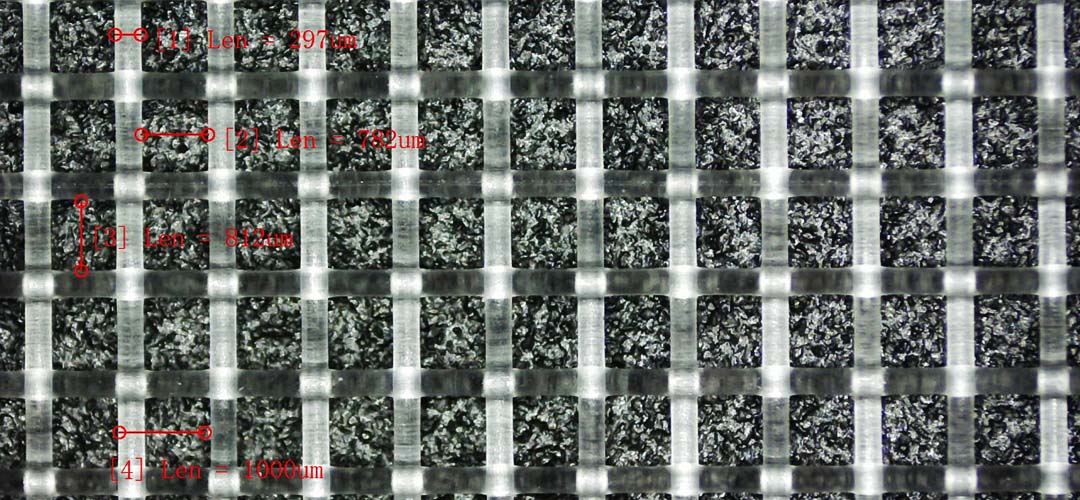

When it comes to choosing the right Micron Filter Mesh material for your industry, there are several options to consider. One of the most popular choices is stainless steel, known for its durability, corrosion resistance, and high strength. In this article, we will explore the benefits of using stainless steel micron filter mesh materials in various industries.

Stainless steel micron filter mesh materials offer a number of advantages that make them ideal for a wide range of applications. One of the key benefits of stainless steel is its resistance to corrosion. This makes it an excellent choice for industries that require filtration in harsh environments or with corrosive materials. Stainless steel micron filter mesh materials are able to withstand exposure to chemicals, high temperatures, and moisture without degrading or losing their effectiveness.

In addition to their corrosion resistance, stainless steel micron filter mesh materials are also incredibly durable. They are able to withstand heavy use and high pressure without becoming damaged or losing their shape. This durability ensures that stainless steel micron filter mesh materials have a long lifespan, making them a cost-effective choice for industries looking for a reliable filtration solution.

Another benefit of using stainless steel micron filter mesh materials is their high strength. Stainless steel is a strong material that is able to withstand heavy loads and high pressures without breaking or deforming. This makes it an ideal choice for industries that require filtration in demanding conditions or with large volumes of material to process.

Stainless steel micron filter mesh materials are also easy to clean and maintain. They can be easily washed or sterilized, making them a hygienic choice for industries that require strict cleanliness standards. This ease of maintenance ensures that stainless steel micron filter mesh materials are able to provide consistent and reliable filtration over time.

In addition to their practical benefits, stainless steel micron filter mesh materials also offer a professional and polished appearance. This makes them a popular choice for industries that require filtration solutions that are both functional and aesthetically pleasing. Stainless steel micron filter mesh materials can be customized to meet specific size and shape requirements, making them a versatile choice for a wide range of applications.

Overall, stainless steel micron filter mesh materials offer a number of benefits that make them an excellent choice for industries looking for a reliable and durable filtration solution. Their corrosion resistance, durability, high strength, ease of maintenance, and professional appearance make them a versatile choice for a wide range of applications. Whether you work in the food and beverage industry, pharmaceuticals, petrochemicals, or any other industry that requires filtration, stainless steel micron filter mesh materials are a reliable and cost-effective choice.

Comparing Nylon and Polyester Micron Filter Mesh Materials

When it comes to choosing the right micron filter mesh material for your industry, there are a few key factors to consider. Two of the most popular options on the market are nylon and polyester. Both materials have their own unique properties and benefits, so it’s important to understand the differences between them in order to make an informed decision.

Nylon micron filter mesh is known for its strength and durability. It is a synthetic material that is resistant to abrasion and chemicals, making it ideal for industries that require a high level of filtration. nylon mesh is also known for its flexibility, which allows it to conform to different shapes and sizes without losing its integrity. This makes it a versatile option for a wide range of applications.

On the other hand, polyester micron filter mesh is valued for its resistance to heat and moisture. Polyester is a synthetic material that is known for its ability to withstand high temperatures and harsh environments. This makes it a popular choice for industries that require filtration in extreme conditions. Polyester mesh is also easy to clean and maintain, making it a cost-effective option for businesses looking to reduce maintenance costs.

When comparing nylon and polyester micron filter mesh materials, it’s important to consider the specific needs of your industry. If you require a material that is strong and durable, nylon mesh may be the best option for you. Its resistance to abrasion and chemicals makes it a reliable choice for industries that require a high level of filtration.

On the other hand, if you work in an industry that requires filtration in extreme conditions, polyester mesh may be the better choice. Its resistance to heat and moisture makes it a durable option for industries that operate in harsh environments. Polyester mesh is also easy to clean and maintain, making it a cost-effective option for businesses looking to reduce maintenance costs.

In conclusion, both nylon and polyester micron filter mesh materials have their own unique properties and benefits. The key is to understand the specific needs of your industry in order to choose the material that best suits your requirements. Whether you require strength and durability or resistance to heat and moisture, there is a micron filter mesh material that is right for you. By carefully considering the properties of nylon and polyester mesh, you can make an informed decision that will benefit your business in the long run.

Factors to Consider When Choosing Micron Filter Mesh Materials for Your Industry

When it comes to choosing the right micron filter mesh materials for your industry, there are several factors to consider. The type of material you choose can have a significant impact on the effectiveness and efficiency of your filtration system. In this article, we will discuss some of the key factors to consider when selecting micron filter mesh materials for your industry.

One of the most important factors to consider when choosing micron filter mesh materials is the type of contaminants you are trying to remove from your process. Different materials are better suited for filtering out specific types of contaminants, so it is important to understand the composition of the substances you are trying to filter. For example, if you are filtering out large particles, a coarser mesh material may be sufficient. However, if you are trying to remove smaller particles or contaminants, a finer mesh material may be necessary.

Another important factor to consider when choosing micron filter mesh materials is the temperature and pressure conditions of your filtration system. Some materials are better suited for high-temperature or high-pressure applications, while others may degrade or become less effective under these conditions. It is important to choose a material that can withstand the specific operating conditions of your filtration system to ensure optimal performance and longevity.

In addition to the type of contaminants and operating conditions, it is also important to consider the compatibility of the micron filter mesh materials with the chemicals and solvents used in your industry. Some materials may react with certain chemicals or solvents, leading to degradation or contamination of the filtration system. It is important to choose a material that is chemically resistant and compatible with the substances used in your industry to prevent any adverse effects on the filtration process.

Furthermore, the durability and longevity of the micron filter mesh materials should also be taken into consideration. Some materials may wear out or degrade over time, leading to decreased filtration efficiency and increased maintenance costs. It is important to choose a material that is durable and long-lasting to ensure consistent and reliable filtration performance.

Cost is another important factor to consider when choosing micron filter mesh materials for your industry. While it may be tempting to opt for the cheapest option, it is important to consider the long-term costs and benefits of different materials. A higher-quality material may have a higher upfront cost but can provide better filtration performance and longevity, ultimately saving you money in the long run.

In conclusion, choosing the right micron filter mesh materials for your industry is a critical decision that can have a significant impact on the effectiveness and efficiency of your filtration system. By considering factors such as the type of contaminants, operating conditions, chemical compatibility, durability, and cost, you can select a material that meets your specific needs and requirements. It is important to conduct thorough research and consult with industry experts to ensure that you choose the best micron filter mesh materials for your industry.