Table of Contents

Benefits of Using High Flow Pleated Filters for Industrial Applications

In the world of industrial applications, efficiency is key. Companies are constantly looking for ways to streamline their processes and maximize productivity. One way to achieve this is by using high flow pleated filters. These filters offer a number of benefits that can help businesses operate more efficiently and effectively.

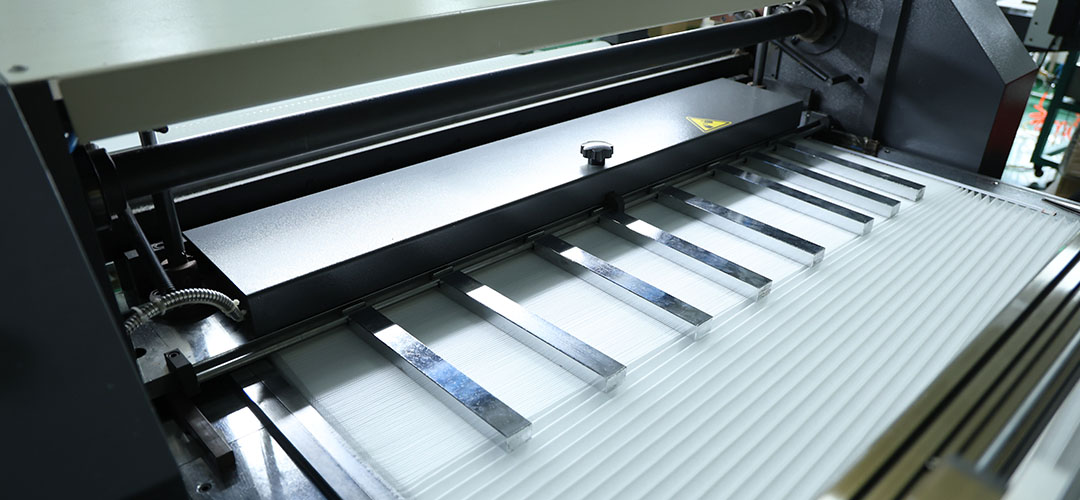

High flow pleated filters are designed to handle large volumes of liquid or gas flow while maintaining high levels of filtration efficiency. This means that they can process more material in a shorter amount of time, leading to increased productivity and reduced downtime. In addition, high flow pleated filters are typically more durable than traditional filters, which means they can last longer and require less frequent replacement. This can result in cost savings for businesses in the long run.

Another benefit of using high flow pleated filters is their versatility. These filters can be used in a wide range of industrial applications, from water treatment to chemical processing to food and beverage production. This versatility makes them a valuable tool for businesses that need to filter a variety of substances in different environments. High flow pleated filters can also be customized to meet specific filtration requirements, making them a flexible and adaptable solution for a wide range of industries.

In addition to their efficiency and versatility, high flow pleated filters are also easy to install and maintain. Unlike some other types of filters that require complex installation procedures or frequent maintenance, high flow pleated filters can be quickly and easily installed in existing systems. This means that businesses can start reaping the benefits of these filters right away, without having to invest a lot of time or resources in installation.

Furthermore, high flow pleated filters are designed to be easy to clean and maintain. This means that businesses can spend less time and money on filter maintenance, freeing up resources to focus on other aspects of their operations. In addition, the durability of high flow pleated filters means that they are less likely to clog or break down, reducing the risk of costly downtime and repairs.

Overall, high flow pleated filters offer a number of benefits for businesses looking to maximize efficiency in their industrial applications. From increased productivity and cost savings to versatility and ease of maintenance, these filters are a valuable tool for businesses in a wide range of industries. By investing in high flow pleated filters, companies can improve their operations and achieve greater success in today’s competitive marketplace.

How to Choose the Right High Flow Pleated Filter for Your System

High flow pleated filters are an essential component in many industrial and commercial systems, helping to remove contaminants and ensure the smooth operation of equipment. Choosing the right high flow pleated filter for your system is crucial to maximizing efficiency and prolonging the lifespan of your equipment. In this article, we will discuss some key factors to consider when selecting a high flow pleated filter for your system.

One of the first things to consider when choosing a high flow pleated filter is the filtration efficiency. The filtration efficiency of a filter is a measure of how well it can remove contaminants from the fluid passing through it. High flow pleated filters are available in a range of efficiencies, from standard to high efficiency, so it is important to select a filter that meets the specific requirements of your system.

Another important factor to consider is the flow rate of the filter. The flow rate of a filter is the maximum rate at which fluid can pass through it while maintaining the desired level of filtration. High flow pleated filters are designed to handle higher flow rates than standard filters, making them ideal for systems with high flow requirements. It is important to select a filter with a flow rate that matches the requirements of your system to ensure optimal performance.

In addition to filtration efficiency and flow rate, it is also important to consider the size and compatibility of the filter. High flow pleated filters come in a range of sizes to fit different systems, so it is important to select a filter that is compatible with your equipment. It is also important to consider the installation requirements of the filter, as some filters may require additional equipment or modifications to be installed properly.

When selecting a high flow pleated filter, it is also important to consider the operating conditions of your system. High flow pleated filters are designed to withstand high pressures and temperatures, so it is important to select a filter that can handle the specific operating conditions of your system. It is also important to consider the maintenance requirements of the filter, as some filters may require more frequent maintenance than others.

In conclusion, choosing the right high flow pleated filter for your system is essential to maximizing efficiency and prolonging the lifespan of your equipment. By considering factors such as filtration efficiency, flow rate, size, compatibility, operating conditions, and maintenance requirements, you can select a filter that meets the specific requirements of your system. High flow pleated filters are an important investment in the performance of your system, so it is important to choose wisely.

Tips for Maintaining and Extending the Lifespan of High Flow Pleated Filters

High flow pleated filters are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases. To ensure optimal performance and longevity of these filters, proper maintenance and care are crucial. In this article, we will discuss some tips for maintaining and extending the lifespan of high flow pleated filters.

First and foremost, regular inspection of the filters is key to identifying any potential issues early on. Inspect the filters for any signs of damage, such as tears or holes in the pleats, which can compromise their effectiveness. Additionally, check for any buildup of dirt or debris on the surface of the filters, as this can impede the flow of liquid or gas through the filter media.

Cleaning the filters on a regular basis is also important for maintaining their efficiency. Depending on the type of contaminants being filtered, the filters may need to be cleaned more frequently. Use a gentle cleaning solution and a soft brush to remove any dirt or debris from the surface of the filters. Avoid using harsh chemicals or abrasive materials, as these can damage the filter media and reduce its effectiveness.

In addition to regular cleaning, it is important to replace the filters according to the manufacturer’s recommendations. Over time, the filter media can become clogged with contaminants, reducing the flow rate and efficiency of the filters. By replacing the filters at the recommended intervals, you can ensure that your filtration system continues to operate at peak performance.

Proper installation of the filters is also crucial for maximizing their efficiency. Ensure that the filters are installed correctly, with the flow direction indicated by the manufacturer. Improper installation can lead to bypassing of contaminants, reducing the effectiveness of the filtration system. If you are unsure about how to install the filters properly, consult the manufacturer’s instructions or seek assistance from a professional.

Regular monitoring of the pressure drop across the filters can also help to identify any issues with the filtration system. A sudden increase in pressure drop may indicate that the filters are becoming clogged and need to be replaced. By monitoring the pressure drop regularly, you can take proactive measures to maintain the efficiency of the filtration system.

In conclusion, high flow pleated filters are essential components in many industrial and commercial applications, providing efficient filtration of liquids and gases. By following these tips for maintaining and extending the lifespan of the filters, you can ensure that your filtration system continues to operate at peak performance. Regular inspection, cleaning, and replacement of the filters, along with proper installation and monitoring of pressure drop, are key to maximizing the efficiency of high flow pleated filter solutions.