Table of Contents

Benefits of Using Nylon Filter Cloth Mesh Solutions for Industrial Filtration Processes

In the world of industrial filtration processes, efficiency is key. Companies rely on filtration systems to remove impurities and contaminants from liquids and gases, ensuring that their products meet quality standards and regulatory requirements. One way to maximize efficiency in these processes is by using nylon filter cloth mesh solutions.

Nylon filter cloth mesh is a versatile and durable material that is well-suited for a wide range of industrial filtration applications. Its fine mesh structure allows for precise filtration, capturing even the smallest particles and impurities. This results in cleaner, purer end products and reduces the risk of contamination.

One of the key benefits of using nylon filter cloth mesh solutions is their high efficiency. The fine mesh structure of nylon filter cloth allows for excellent filtration performance, ensuring that impurities are effectively removed from the liquid or gas being filtered. This results in a higher quality end product and reduces the need for additional processing or treatment.

Another advantage of nylon filter cloth mesh solutions is their durability. Nylon is a strong and resilient material that can withstand high temperatures, pressures, and chemical exposure. This makes nylon filter cloth mesh ideal for use in demanding industrial filtration processes where other materials may fail.

In addition to their efficiency and durability, nylon filter cloth mesh solutions are also highly versatile. They can be customized to meet specific filtration requirements, such as particle size, flow rate, and chemical compatibility. This flexibility allows companies to tailor their filtration systems to their unique needs, ensuring optimal performance and cost-effectiveness.

Furthermore, nylon filter cloth mesh solutions are easy to install and maintain. They can be quickly and easily replaced when needed, minimizing downtime and ensuring continuous operation of the filtration system. This ease of maintenance helps to reduce overall operating costs and improve productivity.

Overall, the benefits of using nylon filter cloth mesh solutions for industrial filtration processes are clear. They offer high efficiency, durability, versatility, and ease of maintenance, making them an ideal choice for companies looking to maximize the performance of their filtration systems.

In conclusion, nylon filter cloth mesh solutions are a valuable tool for companies seeking to improve the efficiency of their industrial filtration processes. By choosing nylon filter cloth mesh, companies can benefit from high filtration performance, durability, versatility, and ease of maintenance. These advantages can help companies achieve cleaner, purer end products, reduce operating costs, and improve overall productivity.

How to Choose the Right Nylon Filter Cloth Mesh Solution for Your Specific Application

Nylon filter cloth mesh solutions are a versatile and efficient option for a wide range of filtration applications. Whether you are looking to remove impurities from liquids or solids, nylon filter cloth mesh can provide the filtration capabilities you need. However, with so many options available on the market, it can be challenging to choose the right nylon filter cloth mesh solution for your specific application. In this article, we will discuss some key factors to consider when selecting a nylon filter cloth mesh solution to maximize efficiency in your filtration process.

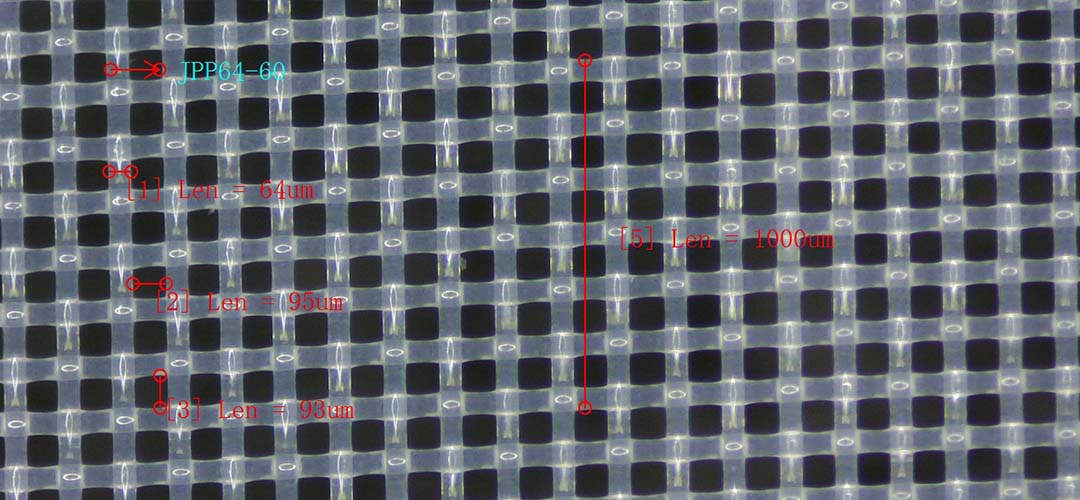

One of the first things to consider when choosing a nylon filter cloth mesh solution is the micron rating. The micron rating refers to the size of the openings in the mesh, which determines the size of particles that can pass through the filter. It is essential to select a nylon filter cloth mesh with a micron rating that is appropriate for the size of particles you need to remove from your liquid or solid material. For example, if you are filtering a liquid with very fine particles, you will need a nylon filter cloth mesh with a lower micron rating to ensure effective filtration.

Another important factor to consider when choosing a nylon filter cloth mesh solution is the weave type. Nylon filter cloth mesh is available in a variety of weave types, including plain weave, twill weave, and Dutch weave. Each weave type offers different filtration properties, so it is essential to select the weave type that best suits your specific application. For example, a plain weave nylon filter cloth mesh is ideal for general filtration applications, while a Dutch weave nylon filter cloth mesh is better suited for applications that require precise particle retention.

In addition to micron rating and weave type, it is also crucial to consider the material of the nylon filter cloth mesh. Nylon filter cloth mesh is typically made from polyamide, which is a durable and chemically resistant material. However, there are different grades of polyamide available, so it is essential to choose a nylon filter cloth mesh made from high-quality polyamide to ensure long-lasting performance and efficient filtration.

When selecting a nylon filter cloth mesh solution, it is also important to consider the operating conditions of your filtration process. Factors such as temperature, pressure, and chemical compatibility can impact the performance of the nylon filter cloth mesh. It is essential to choose a nylon filter cloth mesh that can withstand the specific operating conditions of your filtration process to ensure optimal efficiency and longevity.

In conclusion, choosing the right nylon filter cloth mesh solution is essential for maximizing efficiency in your filtration process. By considering factors such as micron rating, weave type, material, and operating conditions, you can select a nylon filter cloth mesh that meets your specific application requirements. With the right nylon filter cloth mesh solution, you can achieve effective filtration and ensure the quality of your final product.

Tips for Maintaining and Extending the Lifespan of Nylon Filter Cloth Mesh Solutions

Nylon filter cloth mesh solutions are essential components in various industries, including food and beverage, pharmaceutical, and chemical processing. These filter cloths play a crucial role in separating solids from liquids, ensuring product quality and process efficiency. To maximize the efficiency of nylon filter cloth mesh solutions, it is important to properly maintain and extend their lifespan.

One of the key tips for maintaining nylon filter cloth mesh solutions is regular cleaning. Over time, filter cloths can become clogged with debris and contaminants, reducing their effectiveness. To prevent this buildup, it is important to clean the filter cloths regularly. This can be done by rinsing the filter cloths with water or using a mild detergent to remove any trapped particles. Additionally, it is important to inspect the filter cloths regularly for signs of wear and tear, such as holes or tears, and replace them as needed.

Another important tip for maintaining nylon filter cloth mesh solutions is proper storage. When not in use, filter cloths should be stored in a clean, dry environment to prevent mold and mildew growth. It is also important to store filter cloths away from direct sunlight and extreme temperatures, as these can cause the material to degrade over time. By properly storing filter cloths, you can extend their lifespan and ensure they remain effective for longer.

In addition to regular cleaning and proper storage, it is important to handle nylon filter cloth mesh solutions with care. When installing or removing filter cloths, it is important to avoid pulling or stretching the material, as this can cause damage. Instead, gently guide the filter cloth into place and secure it according to the manufacturer’s instructions. By handling filter cloths with care, you can prevent unnecessary damage and extend their lifespan.

Furthermore, it is important to consider the operating conditions when using nylon filter cloth mesh solutions. Different applications may require different types of filter cloths, so it is important to choose the right material for the job. Additionally, it is important to monitor the operating conditions, such as flow rate and pressure, to ensure the filter cloths are performing optimally. By understanding the operating conditions and choosing the right filter cloths, you can maximize efficiency and extend the lifespan of your nylon filter cloth mesh solutions.

In conclusion, nylon filter cloth mesh solutions are essential components in various industries, and proper maintenance is key to maximizing their efficiency and extending their lifespan. By following these tips for maintaining nylon filter cloth mesh solutions, including regular cleaning, proper storage, careful handling, and consideration of operating conditions, you can ensure your filter cloths remain effective for longer. By taking care of your filter cloths, you can improve process efficiency, product quality, and overall performance in your industry.