Table of Contents

Benefits of Using nylon filter mesh in Modern Filtration Systems

In today’s fast-paced world, innovation is key to staying ahead of the competition. This is especially true in the manufacturing industry, where advancements in technology can make a significant impact on the quality and efficiency of products. One area where innovation has been particularly beneficial is in the production of nylon filter mesh for modern filtration systems.

Nylon filter mesh is a versatile material that is used in a wide range of applications, from industrial filtration to medical devices. Its unique properties make it an ideal choice for many different types of filtration systems, including water treatment, air purification, and food processing. One of the key benefits of nylon filter mesh is its durability and strength. Unlike traditional filter materials, such as paper or cloth, nylon is resistant to tearing and can withstand high temperatures and pressures without losing its shape or effectiveness.

Another advantage of nylon filter mesh is its ability to provide precise filtration. The fine mesh structure of nylon allows for the removal of even the smallest particles from a fluid or gas stream, ensuring that the end product is clean and free of contaminants. This level of precision is essential in industries where product quality is paramount, such as pharmaceuticals, electronics, and food and beverage production.

In addition to its durability and precision, nylon filter mesh is also highly customizable. Manufacturers can tailor the size, shape, and density of the mesh to meet the specific requirements of their filtration systems, ensuring optimal performance and efficiency. This level of customization allows for greater flexibility in design and implementation, making nylon filter mesh a versatile and adaptable solution for a wide range of applications.

One of the most significant benefits of using nylon filter mesh in modern filtration systems is its cost-effectiveness. Nylon is a relatively inexpensive material to produce, making it an affordable option for manufacturers looking to reduce production costs without sacrificing quality. Additionally, the durability and longevity of nylon filter mesh mean that it can be used repeatedly without needing frequent replacement, further lowering maintenance and operating expenses.

Furthermore, nylon filter mesh is easy to clean and maintain, reducing downtime and increasing productivity. Unlike some other filter materials that require specialized cleaning procedures or frequent replacement, nylon filter mesh can be quickly and easily rinsed or washed, allowing for continuous operation with minimal interruption. This ease of maintenance is particularly beneficial in industries where downtime can be costly, such as manufacturing and processing plants.

Overall, the benefits of using nylon filter mesh in modern filtration systems are clear. Its durability, precision, customization options, cost-effectiveness, and ease of maintenance make it an ideal choice for a wide range of applications. As technology continues to advance, manufacturers can expect even more innovative solutions to improve the efficiency and effectiveness of their filtration systems. By embracing these advancements and incorporating nylon filter mesh into their processes, companies can stay ahead of the competition and deliver high-quality products to their customers.

Advanced Techniques for Manufacturing High-Quality Nylon Filter Mesh

In the world of filtration, nylon filter mesh has become a popular choice due to its durability, flexibility, and efficiency. With advancements in technology and manufacturing processes, the production of high-quality nylon filter mesh has become more innovative and sophisticated than ever before.

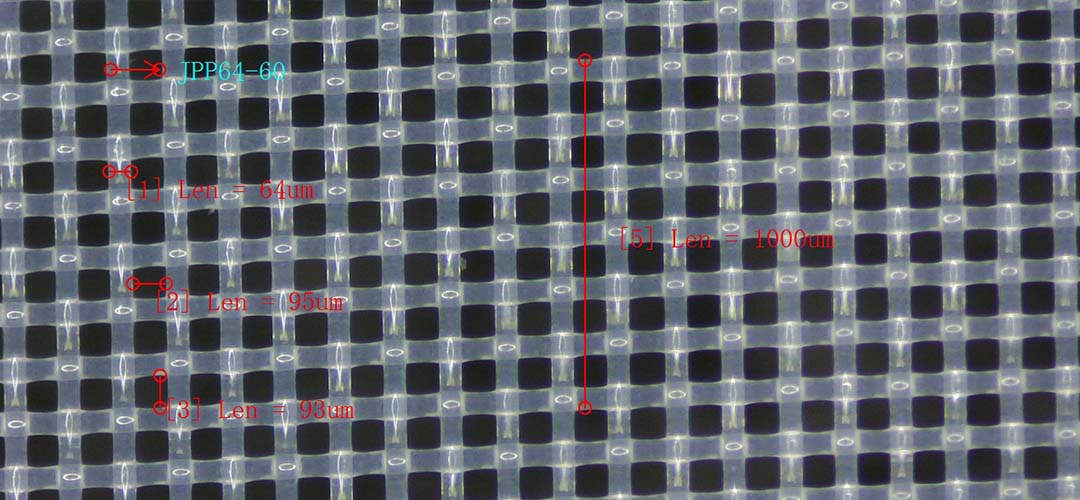

One of the key advancements in nylon filter mesh manufacturing is the use of advanced weaving techniques. Traditional weaving methods have been replaced with computer-controlled looms that can create intricate patterns and designs with precision and accuracy. This allows for the production of nylon filter mesh with uniform pore sizes and consistent mesh openings, resulting in improved filtration performance.

Another innovative technique in nylon filter mesh manufacturing is the use of electrostatically charged fibers. By applying an electrostatic charge to the nylon fibers during the manufacturing process, the filter mesh can attract and capture particles more effectively. This results in a higher filtration efficiency and improved overall performance of the filter mesh.

In addition to advanced weaving techniques and electrostatic charging, manufacturers are also incorporating antimicrobial additives into the nylon filter mesh. These additives help to inhibit the growth of bacteria and mold on the filter mesh, ensuring a cleaner and more hygienic filtration process. This is especially important in applications where cleanliness and sanitation are paramount, such as in the food and beverage industry.

Furthermore, manufacturers are constantly researching and developing new materials and coatings to enhance the properties of nylon filter mesh. By incorporating materials such as carbon nanotubes or graphene into the filter mesh, manufacturers can improve the strength, durability, and conductivity of the mesh, making it more versatile and adaptable to a wide range of filtration applications.

With these advanced techniques and innovations in nylon filter mesh manufacturing, the possibilities for filtration are endless. From industrial applications such as water treatment and air filtration to medical applications such as blood filtration and pharmaceutical processing, nylon filter mesh is a versatile and reliable solution for a wide range of filtration needs.

In conclusion, the manufacturing of high-quality nylon filter mesh has come a long way in recent years, thanks to advancements in technology and innovative techniques. By incorporating advanced weaving methods, electrostatic charging, antimicrobial additives, and new materials and coatings, manufacturers are able to produce nylon filter mesh that is more efficient, durable, and versatile than ever before. As the demand for high-quality filtration solutions continues to grow, the future of nylon filter mesh manufacturing looks bright, with endless possibilities for innovation and improvement.

Applications of Innovative Nylon Filter Mesh in Various Industries

Innovative Nylon Filter Mesh Manufacturing for Modern Filtration

Nylon filter mesh has become an essential component in various industries due to its durability, flexibility, and efficiency in filtering out impurities. With advancements in technology, manufacturers have been able to develop innovative nylon filter mesh that meets the demands of modern filtration systems. These new developments have opened up a world of possibilities for applications in industries such as food and beverage, pharmaceuticals, automotive, and more.

One of the key advantages of using nylon filter mesh is its ability to withstand high temperatures and pressures without compromising its filtering capabilities. This makes it an ideal choice for industries that require precise filtration of liquids and gases. The innovative manufacturing processes used to create nylon filter mesh have resulted in products that are not only durable but also highly efficient in capturing even the smallest particles.

In the food and beverage industry, nylon filter mesh is commonly used in the production of beverages, dairy products, and other liquid foods. The fine mesh size of the filters ensures that any impurities or contaminants are removed, resulting in a clean and safe product for consumers. Additionally, the flexibility of nylon filter mesh allows for easy installation and maintenance, making it a cost-effective solution for food and beverage manufacturers.

In the pharmaceutical industry, the use of nylon filter mesh is crucial in ensuring the purity of drugs and medical devices. The high-quality materials used in manufacturing nylon filter mesh prevent any leaching or contamination, making it a reliable choice for pharmaceutical companies. The innovative design of the mesh also allows for precise filtration, ensuring that only the desired particles are retained while impurities are removed.

Automotive manufacturers also benefit from the use of nylon filter mesh in their production processes. The durability and flexibility of nylon filter mesh make it an ideal choice for filtering out contaminants in engine oil, fuel, and other fluids. This helps to prolong the life of automotive components and improve overall performance. Additionally, the innovative manufacturing processes used to create nylon filter mesh result in products that are resistant to chemicals and abrasion, making them suitable for use in harsh automotive environments.

In the water treatment industry, nylon filter mesh is used to remove impurities and contaminants from water sources. The fine mesh size of the filters ensures that even the smallest particles are captured, resulting in clean and safe drinking water. The innovative manufacturing processes used to create nylon filter mesh have also led to the development of filters that are resistant to clogging and fouling, making them ideal for long-term use in water treatment facilities.

Overall, the applications of innovative nylon filter mesh in various industries are vast and continue to grow as technology advances. The durability, flexibility, and efficiency of nylon filter mesh make it a valuable component in modern filtration systems. With ongoing research and development, manufacturers are constantly improving the design and performance of nylon filter mesh, ensuring that it remains a top choice for industries that require precise and reliable filtration.