Table of Contents

Benefits of Using micron nylon mesh in Industrial Screening Systems

Micron nylon mesh has become an essential component in industrial screening systems due to its numerous benefits and applications. This versatile material is known for its durability, flexibility, and efficiency, making it an ideal choice for a wide range of industries. In this article, we will explore the benefits of using micron nylon mesh in industrial screening systems and how it can improve the overall performance and productivity of various processes.

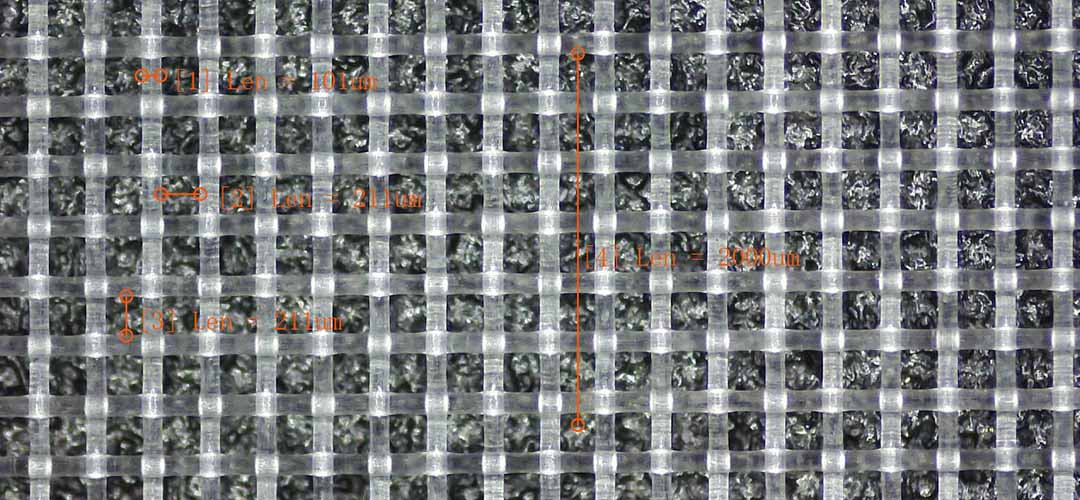

One of the key advantages of micron nylon mesh is its ability to provide precise and accurate screening results. The fine mesh size allows for the separation of particles based on their size, ensuring that only the desired materials pass through while unwanted particles are filtered out. This level of precision is crucial in industries such as pharmaceuticals, food processing, and chemical manufacturing, where product quality and consistency are paramount.

In addition to its precision, micron nylon mesh is also highly durable and long-lasting. Its strong and resilient nature allows it to withstand harsh operating conditions, including high temperatures, corrosive chemicals, and heavy loads. This durability ensures that the mesh maintains its integrity and performance over time, reducing the need for frequent replacements and maintenance. This not only saves time and money but also improves the overall efficiency of the screening system.

Furthermore, micron nylon mesh is incredibly flexible and versatile, making it suitable for a wide range of applications. It can be easily customized to meet specific requirements, such as different mesh sizes, shapes, and configurations. This flexibility allows for greater adaptability in various industrial processes, ensuring that the screening system can effectively handle different materials and operating conditions.

Another benefit of using micron nylon mesh in industrial screening systems is its cost-effectiveness. Compared to other screening materials, such as metal or synthetic fibers, nylon mesh is more affordable and readily available. This cost-effectiveness makes it an attractive option for businesses looking to optimize their screening processes without breaking the bank. Additionally, the longevity of nylon mesh means that companies can enjoy long-term savings on maintenance and replacement costs.

Moreover, micron nylon mesh is easy to clean and maintain, further enhancing its efficiency and usability in industrial applications. Its smooth surface allows for quick and thorough cleaning, reducing downtime and ensuring continuous operation. This ease of maintenance is particularly beneficial in industries where cleanliness and hygiene are critical, such as food processing and pharmaceuticals.

In conclusion, the benefits of using micron nylon mesh in industrial screening systems are clear. Its precision, durability, flexibility, cost-effectiveness, and ease of maintenance make it an indispensable component in various industries. By incorporating micron nylon mesh into their screening processes, businesses can improve efficiency, productivity, and product quality. As technology continues to advance, micron nylon mesh will undoubtedly play a crucial role in shaping the future of industrial screening systems.

How Micron Nylon Mesh Improves Efficiency in Industrial Applications

Micron nylon mesh has become an essential component in various industrial applications, particularly in screening systems. This versatile material offers a wide range of benefits that improve efficiency and productivity in manufacturing processes. From filtering out impurities to separating particles of different sizes, micron nylon mesh plays a crucial role in ensuring the quality and consistency of the final product.

One of the key advantages of using micron nylon mesh in screening systems is its ability to provide precise and accurate separation of particles. The fine mesh openings allow for the efficient removal of unwanted contaminants, ensuring that only the desired particles pass through. This level of precision is essential in industries such as pharmaceuticals, food processing, and chemical manufacturing, where product purity is of utmost importance.

In addition to its precision, micron nylon mesh also offers excellent durability and longevity. The material is resistant to abrasion, chemicals, and high temperatures, making it ideal for use in harsh industrial environments. This durability ensures that the mesh can withstand the rigors of continuous operation without compromising its performance, resulting in cost savings and increased efficiency for businesses.

Furthermore, micron nylon mesh is highly customizable, allowing for the creation of screens with specific mesh sizes and configurations to meet the unique requirements of each application. This flexibility enables manufacturers to tailor their screening systems to achieve optimal results, whether it be in particle size distribution, flow rate, or overall efficiency. By utilizing micron nylon mesh, businesses can improve the accuracy and effectiveness of their screening processes, leading to higher quality products and increased customer satisfaction.

Another significant benefit of using micron nylon mesh in industrial applications is its ease of maintenance. The material is easy to clean and maintain, reducing downtime and ensuring continuous operation of screening systems. This ease of maintenance translates to lower operating costs and improved overall efficiency for businesses, as it minimizes the need for frequent replacements or repairs.

Moreover, micron nylon mesh is lightweight and easy to handle, making it simple to install and replace in screening systems. This ease of handling allows for quick and efficient changes to the mesh configuration, enabling businesses to adapt to changing production requirements with minimal disruption. By utilizing micron nylon mesh, manufacturers can streamline their operations and improve overall productivity, ultimately leading to increased profitability and competitiveness in the market.

In conclusion, micron nylon mesh is a valuable tool for improving efficiency in industrial screening systems. Its precision, durability, customization options, ease of maintenance, and handling make it an ideal choice for businesses looking to enhance the quality and consistency of their products. By incorporating micron nylon mesh into their screening processes, manufacturers can achieve higher levels of accuracy, productivity, and cost-effectiveness, ultimately leading to greater success in today’s competitive industrial landscape.

Case Studies Highlighting Successful Implementation of Micron Nylon Mesh in Screening Systems

Micron nylon mesh has become a popular choice for screening systems in various industrial applications due to its durability, flexibility, and efficiency. This versatile material is used in a wide range of industries, including pharmaceuticals, food and beverage, mining, and wastewater treatment. In this article, we will explore some case studies that highlight the successful implementation of micron nylon mesh in screening systems.

One of the key advantages of micron nylon mesh is its ability to provide precise and accurate screening. This is particularly important in industries such as pharmaceuticals, where the quality and purity of the final product are paramount. By using micron nylon mesh in their screening systems, pharmaceutical companies can ensure that only particles of a certain size are allowed to pass through, resulting in a high-quality end product.

In a recent case study, a pharmaceutical company implemented micron nylon mesh in their screening system to separate fine particles from larger ones. By using a mesh with a specific micron size, the company was able to achieve the desired level of separation, resulting in a more efficient and cost-effective production process. The micron nylon mesh also proved to be durable and long-lasting, reducing the need for frequent replacements and maintenance.

Another industry that has benefited from the use of micron nylon mesh in screening systems is the food and beverage industry. In a case study involving a beverage manufacturing company, micron nylon mesh was used to filter out impurities and contaminants from the final product. The company saw a significant improvement in the quality of their beverages, leading to increased customer satisfaction and loyalty.

Mining companies have also found success in using micron nylon mesh in their screening systems. By using a mesh with a specific micron size, mining companies can separate valuable minerals from waste materials more efficiently. This results in higher yields and lower production costs, ultimately leading to increased profitability for the company.

In the wastewater treatment industry, micron nylon mesh has proven to be an effective solution for filtering out solids and contaminants from wastewater. By using micron nylon mesh in their screening systems, wastewater treatment plants can achieve higher levels of purification, resulting in cleaner water that meets regulatory standards. This not only benefits the environment but also helps to protect public health.

Overall, the successful implementation of micron nylon mesh in screening systems across various industries highlights the versatility and effectiveness of this material. Its ability to provide precise and accurate screening, as well as its durability and efficiency, make it a valuable asset for companies looking to improve their production processes and achieve higher levels of quality and purity in their products.

As technology continues to advance, we can expect to see even more innovative uses for micron nylon mesh in screening systems. Its versatility and effectiveness make it a valuable tool for companies looking to stay ahead of the competition and meet the demands of an ever-changing market. By investing in micron nylon mesh for their screening systems, companies can ensure that they are well-equipped to handle the challenges of today’s industrial landscape.