Table of Contents

Innovations in Filtration Technology with nylon mesh fabric

Nylon mesh fabric has emerged as a transformative force in the realm of filtration and screening technologies, offering a blend of durability, versatility, and efficiency that traditional materials simply cannot match. As industries increasingly seek solutions that enhance performance while reducing costs, the adoption of nylon mesh has become a pivotal innovation. This fabric, known for its fine yet robust structure, has redefined the standards of filtration, enabling more precise separation of particles and contaminants across various applications.

One of the most significant advantages of nylon mesh fabric lies in its exceptional strength-to-weight ratio. This characteristic allows for the creation of filters that are not only lightweight but also capable of withstanding high pressures and harsh environments. Consequently, industries such as water treatment, pharmaceuticals, and food processing have embraced nylon mesh as a reliable option for their filtration needs. The ability to maintain structural integrity under challenging conditions ensures that these filters can operate effectively over extended periods, thereby reducing maintenance costs and downtime.

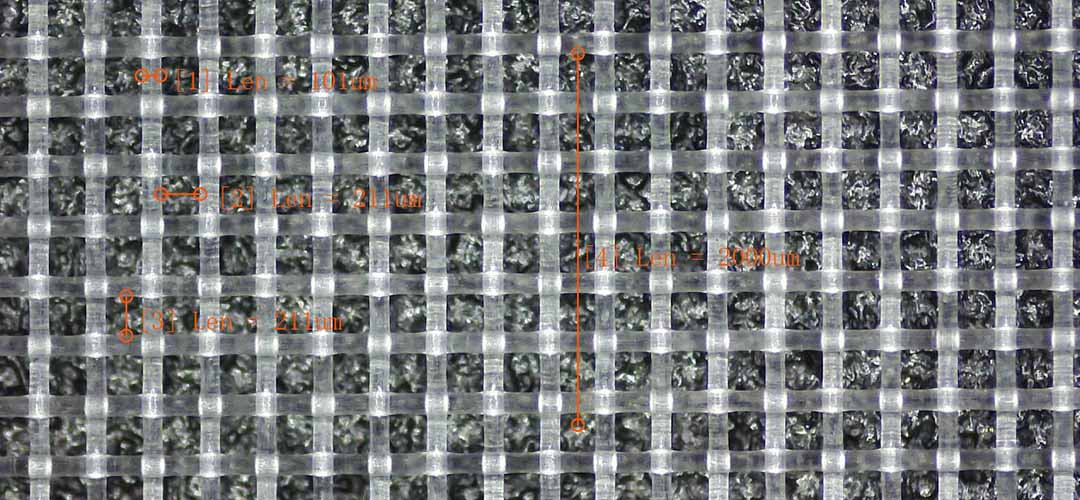

Moreover, the versatility of nylon mesh fabric is evident in its wide range of mesh sizes and configurations. This adaptability enables manufacturers to tailor filtration solutions to specific requirements, whether it be for coarse filtration or ultra-fine screening. For instance, in the water treatment sector, nylon mesh can be engineered to capture larger debris while allowing smaller particles to pass through, thus optimizing the purification process. In contrast, applications in the pharmaceutical industry may require finer mesh sizes to ensure that only the desired compounds are retained, highlighting the fabric’s ability to cater to diverse operational needs.

In addition to its mechanical properties, nylon mesh fabric also offers significant chemical resistance, making it suitable for use in environments where exposure to corrosive substances is a concern. This resilience not only extends the lifespan of filtration systems but also enhances their reliability. As industries continue to prioritize sustainability and efficiency, the longevity of nylon mesh filters contributes to reduced waste and lower overall operational costs. Furthermore, the fabric’s ease of cleaning and maintenance further solidifies its position as a preferred choice in various sectors.

The integration of nylon mesh fabric into filtration technology has also been bolstered by advancements in manufacturing processes. Innovations such as precision weaving and advanced coating techniques have allowed for the production of mesh fabrics that exhibit enhanced performance characteristics. These developments have led to the creation of filters that not only meet but exceed industry standards, providing end-users with confidence in their filtration solutions. As a result, businesses are increasingly turning to nylon mesh as a means to improve product quality and operational efficiency.

As we look to the future, the role of nylon mesh fabric in filtration and screening technologies is poised to expand even further. Ongoing research and development efforts are likely to yield new applications and enhancements, particularly in emerging fields such as nanotechnology and biotechnology. The potential for nylon mesh to facilitate breakthroughs in these areas underscores its importance as a foundational material in modern filtration systems.

In conclusion, the innovations brought about by nylon mesh fabric have revolutionized filtration and screening technologies across multiple industries. Its unique combination of strength, versatility, and chemical resistance positions it as a critical component in the quest for more efficient and effective filtration solutions. As industries continue to evolve and face new challenges, the role of nylon mesh fabric will undoubtedly remain central to the advancement of filtration technology, paving the way for enhanced performance and sustainability.

The Advantages of Nylon Mesh in Industrial Screening Applications

Nylon mesh fabric has emerged as a transformative material in the realm of industrial screening applications, offering a multitude of advantages that enhance efficiency and effectiveness. One of the primary benefits of nylon mesh is its exceptional strength-to-weight ratio. This characteristic allows for the creation of lightweight screens that do not compromise on durability. As industries increasingly seek to optimize their operations, the ability to use a material that is both strong and light is invaluable. This combination not only reduces the overall weight of screening equipment but also minimizes wear and tear, leading to longer service life and reduced maintenance costs.

Moreover, nylon mesh exhibits remarkable resistance to abrasion and chemicals, making it suitable for a wide range of industrial environments. In applications where exposure to harsh substances is inevitable, nylon mesh stands out as a reliable choice. Its ability to withstand corrosive chemicals and abrasive materials ensures that the integrity of the screening process is maintained, thereby enhancing productivity. This resilience is particularly beneficial in industries such as mining, food processing, and wastewater treatment, where the screening materials are subjected to extreme conditions.

In addition to its physical properties, nylon mesh fabric offers versatility in terms of mesh size and configuration. This adaptability allows manufacturers to customize their screening solutions to meet specific operational requirements. Whether the need is for fine filtration or coarse screening, nylon mesh can be engineered to provide the desired level of separation. This flexibility not only improves the efficiency of the screening process but also enables industries to achieve higher purity levels in their final products, which is crucial in sectors like pharmaceuticals and food production.

Another significant advantage of nylon mesh is its ease of installation and maintenance. Unlike traditional metal screens, which can be cumbersome and require specialized tools for installation, nylon mesh is lightweight and can be easily handled. This ease of use translates to reduced downtime during installation and maintenance, allowing operations to continue with minimal disruption. Furthermore, the ability to clean nylon mesh screens without damaging them ensures that they can be reused multiple times, further enhancing their cost-effectiveness.

The thermal stability of nylon mesh also plays a critical role in its application across various industries. It can withstand a wide range of temperatures, making it suitable for processes that involve heat. This thermal resilience ensures that the mesh maintains its structural integrity and performance, even in high-temperature environments. As industries continue to evolve and adopt more complex processes, the ability to rely on materials that can perform under varying conditions becomes increasingly important.

Lastly, the environmental impact of nylon mesh fabric cannot be overlooked. As sustainability becomes a focal point for many industries, the use of nylon mesh contributes to reducing waste. Its durability and reusability mean that fewer materials are needed over time, which aligns with the growing emphasis on sustainable practices. By choosing nylon mesh for screening applications, companies not only enhance their operational efficiency but also contribute to a more sustainable future.

In conclusion, the advantages of nylon mesh fabric in industrial screening applications are manifold. Its strength, chemical resistance, versatility, ease of maintenance, thermal stability, and environmental benefits position it as a superior choice for industries seeking to improve their screening processes. As businesses continue to prioritize efficiency and sustainability, the adoption of nylon mesh is likely to expand, further revolutionizing the filtration and screening landscape.

Environmental Impact of Nylon Mesh Fabric in Water Filtration Systems

Nylon mesh fabric has emerged as a pivotal material in the realm of water filtration systems, significantly influencing both efficiency and environmental sustainability. As the demand for clean water continues to escalate globally, the role of innovative materials like nylon mesh cannot be overstated. This fabric, known for its durability and versatility, has transformed traditional filtration methods, offering a more effective solution to water purification challenges. The environmental impact of nylon mesh fabric in water filtration systems is profound, as it not only enhances the filtration process but also contributes to reducing waste and promoting sustainability.

One of the primary advantages of nylon mesh fabric is its ability to provide superior filtration capabilities. The fine mesh structure allows for the effective removal of contaminants, including sediments, bacteria, and other harmful particles, ensuring that the water is not only clean but also safe for consumption. This efficiency is crucial in areas where water quality is compromised, as it directly impacts public health. By utilizing nylon mesh in filtration systems, communities can achieve higher standards of water purity, which is essential for both human health and environmental preservation.

Moreover, the longevity of nylon mesh fabric plays a significant role in its environmental impact. Unlike traditional filtration materials that may require frequent replacement, nylon mesh is designed to withstand harsh conditions and prolonged use. This durability translates to less frequent disposal and, consequently, a reduction in waste generated from discarded filtration materials. In an era where environmental concerns are paramount, the ability to minimize waste through the use of long-lasting materials is a critical advantage. By extending the lifespan of filtration systems, nylon mesh fabric not only reduces the environmental footprint but also lowers operational costs for water treatment facilities.

In addition to its durability, nylon mesh fabric is also lightweight and easy to handle, which simplifies the installation and maintenance processes of filtration systems. This ease of use encourages more widespread adoption of advanced filtration technologies, particularly in developing regions where resources may be limited. As communities gain access to efficient water filtration solutions, the overall quality of life improves, leading to healthier populations and more sustainable practices. The integration of nylon mesh fabric into water filtration systems thus serves as a catalyst for positive change, promoting both environmental stewardship and social responsibility.

Furthermore, the production of nylon mesh fabric has evolved to incorporate more sustainable practices. Manufacturers are increasingly focusing on reducing the environmental impact of their production processes, utilizing recycled materials and implementing energy-efficient methods. This shift not only enhances the sustainability of nylon mesh fabric itself but also aligns with the broader goals of reducing carbon footprints and promoting eco-friendly practices across industries. As consumers and businesses alike become more environmentally conscious, the demand for sustainable materials like nylon mesh fabric is likely to grow, further driving innovation in water filtration technologies.

In conclusion, the environmental impact of nylon mesh fabric in water filtration systems is significant and multifaceted. By enhancing filtration efficiency, reducing waste, and promoting sustainable production practices, nylon mesh fabric stands at the forefront of efforts to improve water quality and protect public health. As the world continues to grapple with water scarcity and pollution, the adoption of advanced materials like nylon mesh will be crucial in developing effective solutions that not only meet the needs of today but also safeguard the environment for future generations. The ongoing evolution of filtration technologies, driven by materials such as nylon mesh, represents a vital step toward achieving a more sustainable and healthier world.