Table of Contents

Benefits of Using High-Tech Materials in nylon filter mesh

The utilization of high-tech materials in the production of nylon filter mesh has revolutionized various industries, enhancing performance and efficiency in filtration processes. One of the primary benefits of employing advanced materials is the significant improvement in durability and strength. Traditional nylon may not withstand harsh environmental conditions, but high-tech variants are engineered to resist abrasion, chemical exposure, and extreme temperatures. This resilience ensures that the filter mesh maintains its integrity over time, reducing the need for frequent replacements and thereby lowering operational costs.

Moreover, high-tech materials contribute to superior filtration capabilities. The precision engineering involved in creating these advanced meshes allows for tighter pore sizes and more uniform distribution, which enhances the mesh’s ability to capture particles of varying sizes. This is particularly beneficial in applications such as water treatment, food processing, and pharmaceuticals, where maintaining high levels of purity is essential. As a result, industries can achieve compliance with stringent regulatory standards while ensuring the safety and quality of their products.

In addition to improved durability and filtration efficiency, high-tech materials also offer enhanced versatility. Manufacturers can tailor the properties of nylon filter mesh to meet specific application requirements, such as varying mesh sizes, thicknesses, and chemical resistances. This customization enables businesses to optimize their filtration systems for unique operational needs, thereby increasing overall productivity. For instance, in the automotive industry, specialized nylon filter meshes can be designed to withstand high temperatures and aggressive chemicals, ensuring reliable performance in demanding environments.

Furthermore, the lightweight nature of high-tech nylon materials contributes to ease of handling and installation. This characteristic is particularly advantageous in large-scale operations where heavy equipment can complicate maintenance and replacement tasks. By utilizing lighter filter meshes, companies can streamline their processes, reduce labor costs, and enhance overall efficiency. The ease of installation also minimizes downtime, allowing businesses to maintain continuous operations without significant interruptions.

Another noteworthy advantage of high-tech materials in nylon filter mesh is their environmental impact. Many advanced materials are designed with sustainability in mind, incorporating recycled components or being fully recyclable themselves. This aligns with the growing emphasis on eco-friendly practices across industries, enabling companies to reduce their carbon footprint while still achieving high-performance filtration. By choosing high-tech nylon filter meshes, businesses not only enhance their operational efficiency but also contribute to broader environmental goals.

Additionally, the integration of high-tech materials often leads to innovations in filtration technology. For example, some advanced nylon meshes are now being developed with antimicrobial properties, which can inhibit the growth of bacteria and other pathogens. This is particularly relevant in healthcare and food processing sectors, where hygiene is paramount. Such innovations not only improve the safety of the end products but also enhance the reputation of companies that prioritize cutting-edge technology in their operations.

In conclusion, the benefits of using high-tech materials in nylon filter mesh are manifold, encompassing enhanced durability, superior filtration capabilities, versatility, ease of handling, and environmental sustainability. As industries continue to evolve and face new challenges, the adoption of these advanced materials will play a crucial role in driving efficiency and innovation. By investing in high-tech nylon filter mesh, businesses position themselves at the forefront of their respective fields, ensuring they meet both current demands and future challenges with confidence.

Innovations in High-Tech Materials for Improved Filter Performance

High-Tech Materials Behind Nylon Filter Mesh Performance

In the world of filtration, the performance of filter materials is crucial to achieving optimal results. One material that has gained popularity in recent years for its exceptional performance is nylon. Nylon filter mesh is known for its durability, flexibility, and efficiency in capturing particles of various sizes. But what exactly makes nylon filter mesh stand out from other materials? The answer lies in the high-tech materials used in its production.

Nylon filter mesh is made from a synthetic polymer known as polyamide, which is a type of plastic that is known for its strength and durability. Polyamide is a versatile material that can be engineered to have specific properties, such as high tensile strength, chemical resistance, and heat resistance. These properties make nylon an ideal material for filter mesh applications, where the material needs to withstand harsh conditions and maintain its integrity over time.

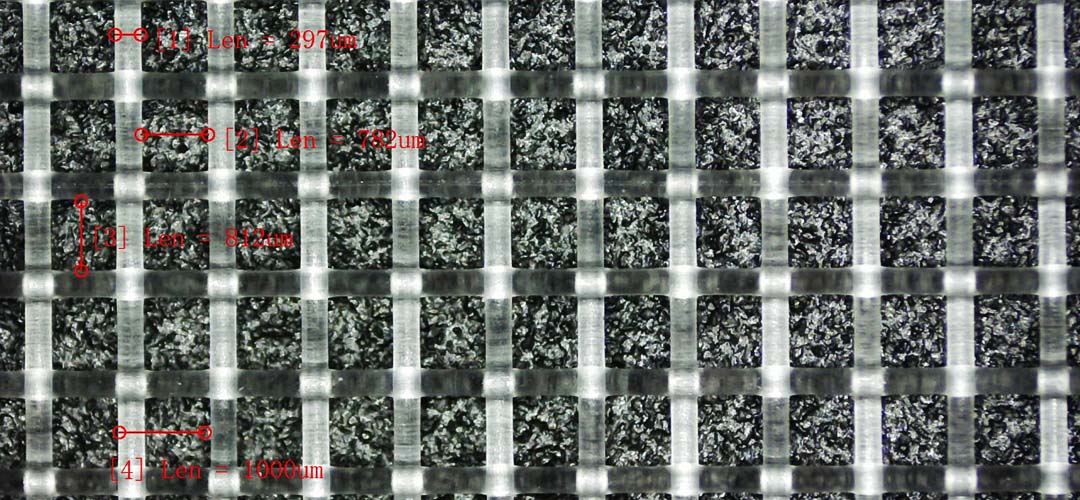

One of the key factors that contribute to the performance of nylon filter mesh is its uniform pore size distribution. The pores in the mesh are precisely engineered to be consistent in size, allowing for efficient filtration of particles of various sizes. This uniformity in pore size distribution ensures that the mesh can capture particles effectively without clogging or compromising the flow rate.

Another important aspect of nylon filter mesh is its surface properties. The surface of the mesh can be modified to enhance its filtration efficiency by adding coatings or treatments that improve its adhesion properties. These surface modifications can help to increase the mesh’s ability to capture particles and prevent them from passing through the filter.

Furthermore, the high-tech materials used in the production of nylon filter mesh also contribute to its flexibility and durability. Nylon is a flexible material that can be easily molded into different shapes and sizes, making it suitable for a wide range of filtration applications. Additionally, nylon is resistant to abrasion and tearing, ensuring that the filter mesh can withstand the rigors of continuous use without deteriorating.

In addition to its physical properties, nylon filter mesh is also known for its chemical resistance. Nylon is resistant to a wide range of chemicals, making it suitable for use in applications where exposure to corrosive substances is a concern. This chemical resistance ensures that the filter mesh can maintain its performance even in challenging environments.

Overall, the high-tech materials used in the production of nylon filter mesh play a crucial role in its performance and efficiency. From its uniform pore size distribution to its surface properties and chemical resistance, nylon filter mesh is a versatile material that can meet the demands of various filtration applications. As technology continues to advance, we can expect to see further innovations in high-tech materials that will further enhance the performance of filter materials like nylon filter mesh.

Sustainability and Environmental Impact of High-Tech Materials in Nylon Filter Mesh

High-Tech Materials Behind Nylon Filter Mesh Performance

In the world of filtration, nylon filter mesh has become a popular choice due to its high performance and durability. But what exactly makes this material so effective? The answer lies in the high-tech materials that are used to create it.

Nylon filter mesh is made from a synthetic polymer known as polyamide, which is a type of plastic that is known for its strength and flexibility. This material is then woven into a mesh pattern that allows for the filtration of particles while still allowing for the flow of liquids or gases.

One of the key benefits of using nylon filter mesh is its sustainability and environmental impact. Unlike traditional filter materials such as paper or cotton, nylon is a synthetic material that can be recycled and reused multiple times without losing its effectiveness. This means that less waste is produced and fewer resources are used in the production of new filters.

Additionally, nylon filter mesh is highly durable and long-lasting, which means that it does not need to be replaced as frequently as other types of filters. This not only saves money in the long run but also reduces the amount of waste that is generated from disposable filters.

Another important aspect of the high-tech materials used in nylon filter mesh is their ability to withstand harsh conditions. Nylon is resistant to chemicals, heat, and abrasion, making it ideal for use in a wide range of industries such as pharmaceuticals, food and beverage, and automotive.

Furthermore, the high-tech materials used in nylon filter mesh are designed to be lightweight and easy to handle, making them ideal for applications where portability is important. This makes nylon filter mesh a versatile option for a variety of filtration needs.

In terms of environmental impact, the production of nylon filter mesh does have some drawbacks. The process of creating polyamide, the main component of nylon, does require the use of fossil fuels and chemicals, which can contribute to air and water pollution. However, many manufacturers are working to reduce their environmental footprint by using more sustainable practices and materials in their production processes.

Overall, the high-tech materials behind nylon filter mesh play a crucial role in its performance and effectiveness. From its durability and resistance to its sustainability and environmental impact, nylon filter mesh is a top choice for industries looking for a reliable and efficient filtration solution.

In conclusion, the use of high-tech materials in nylon filter mesh is a key factor in its success as a filtration material. With its durability, sustainability, and versatility, nylon filter mesh is a top choice for industries looking to improve their filtration processes while minimizing their environmental impact. By continuing to innovate and improve upon the materials used in nylon filter mesh, manufacturers can ensure that this material remains a top choice for years to come.