Table of Contents

Benefits of Using High-Performance 75 Micron Screens for Precise Filtration

High-performance 75 micron screens are essential tools for achieving precise filtration in various industries. These screens are designed to effectively remove impurities and contaminants from liquids and gases, ensuring that the final product meets the highest quality standards. By using high-performance 75 micron screens, businesses can improve the efficiency of their filtration processes and reduce the risk of product contamination.

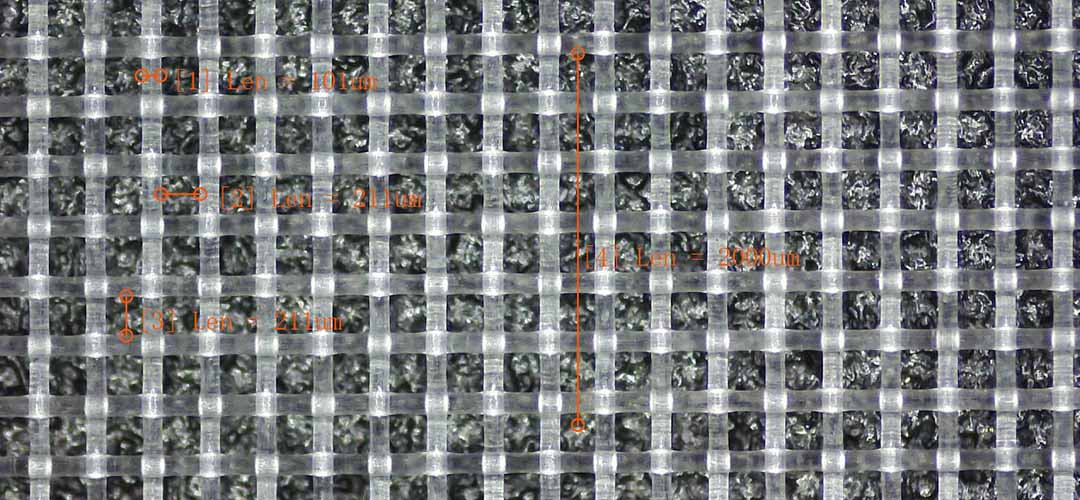

One of the key benefits of using high-performance 75 micron screens is their ability to provide accurate filtration results. These screens are designed to capture particles as small as 75 microns, ensuring that even the tiniest impurities are removed from the liquid or gas being filtered. This level of precision is crucial for industries that require strict quality control measures, such as pharmaceuticals, food and beverage, and electronics manufacturing.

In addition to their precise filtration capabilities, high-performance 75 micron screens are also highly durable and long-lasting. These screens are typically made from high-quality materials that can withstand harsh operating conditions, such as high temperatures, corrosive chemicals, and high pressure. This durability ensures that the screens can maintain their effectiveness over time, reducing the need for frequent replacements and saving businesses time and money in the long run.

Furthermore, high-performance 75 micron screens are designed to be easy to clean and maintain. This makes them ideal for industries that require frequent filter changes or regular maintenance, as it minimizes downtime and ensures that the filtration process remains efficient and effective. By using high-performance 75 micron screens, businesses can streamline their filtration processes and improve overall productivity.

Another key benefit of using high-performance 75 micron screens is their versatility. These screens can be customized to meet the specific needs of different industries and applications, ensuring that businesses can achieve the precise filtration results they require. Whether filtering liquids, gases, or solids, high-performance 75 micron screens can be tailored to provide the optimal solution for each unique situation.

Additionally, high-performance 75 micron screens are cost-effective solutions for businesses looking to improve their filtration processes. By investing in high-quality screens that offer precise filtration results and long-lasting durability, businesses can reduce the risk of product contamination and ensure that their final products meet the highest quality standards. This can lead to increased customer satisfaction, improved brand reputation, and ultimately, higher profits for the business.

In conclusion, high-performance 75 micron screens are essential tools for achieving precise filtration in various industries. These screens offer a range of benefits, including accurate filtration results, durability, ease of maintenance, versatility, and cost-effectiveness. By investing in high-quality screens that meet their specific needs, businesses can improve the efficiency of their filtration processes, reduce the risk of product contamination, and ultimately, achieve higher levels of success in their respective industries.

How to Choose the Right High-Performance 75 micron screen for Your Filtration Needs

When it comes to filtration, precision is key. Whether you are in the pharmaceutical, food and beverage, or chemical industry, having the right filtration system in place is crucial for ensuring the quality and purity of your products. One component that plays a significant role in the filtration process is the screen. High-performance 75-micron screens are designed to provide precise filtration, capturing even the smallest particles to ensure a clean and efficient process.

Choosing the right high-performance 75-micron screen for your filtration needs requires careful consideration of several factors. The first step is to assess the specific requirements of your application. Consider the type of material being filtered, the size of particles that need to be captured, and the flow rate of the process. These factors will help determine the type of screen material, mesh size, and design that will best suit your needs.

When selecting a high-performance 75-micron screen, it is essential to consider the material of construction. Stainless steel screens are a popular choice for their durability and resistance to corrosion. They are suitable for a wide range of applications and can withstand high temperatures and pressures. Other materials, such as nylon and polyester, are also available and may be more suitable for certain applications. Consider the compatibility of the screen material with the substances being filtered to ensure optimal performance and longevity.

Mesh size is another critical factor to consider when choosing a high-performance 75-micron screen. The mesh size refers to the number of openings per inch in the screen and determines the size of particles that can pass through. A finer mesh size will capture smaller particles but may also restrict flow, while a larger mesh size will allow for higher flow rates but may not provide as precise filtration. Consider the size of particles that need to be captured and the desired flow rate to determine the appropriate mesh size for your application.

In addition to material and mesh size, the design of the screen is also important. High-performance 75-micron screens are available in various configurations, including woven wire, perforated plate, and wedge wire. Each design offers unique benefits in terms of strength, durability, and filtration efficiency. Consider the specific requirements of your application, such as pressure and temperature conditions, to determine the most suitable screen design for your needs.

When choosing a high-performance 75-micron screen, it is essential to work with a reputable supplier who can provide expert guidance and support. Look for a supplier with a proven track record of delivering high-quality filtration products and excellent customer service. A knowledgeable supplier will be able to help you select the right screen for your application, provide technical support, and ensure timely delivery of your order.

In conclusion, choosing the right high-performance 75-micron screen for your filtration needs is essential for ensuring precise and efficient filtration. Consider the material, mesh size, and design of the screen to meet the specific requirements of your application. Work with a reputable supplier to ensure you receive high-quality products and expert support. With the right high-performance 75-micron screen in place, you can achieve optimal filtration results and maintain the quality and purity of your products.

Maintenance Tips for Ensuring Optimal Performance of High-Performance 75 Micron Screens

High-performance 75 micron screens are essential components in many industrial processes that require precise filtration. These screens are designed to remove impurities and contaminants from liquids, ensuring that the final product meets the required quality standards. To maintain the optimal performance of these screens, it is important to follow a few key maintenance tips.

One of the most important maintenance tips for high-performance 75 micron screens is regular cleaning. Over time, contaminants can build up on the surface of the screen, reducing its effectiveness. To prevent this buildup, it is recommended to clean the screen regularly using a mild detergent and water. This will help to remove any accumulated debris and ensure that the screen continues to operate at peak efficiency.

In addition to regular cleaning, it is also important to inspect the screen for any signs of damage or wear. Even small tears or holes in the screen can significantly impact its performance, allowing contaminants to pass through and potentially compromise the quality of the final product. By inspecting the screen regularly, any issues can be identified and addressed before they escalate into more serious problems.

Another important maintenance tip for high-performance 75 micron screens is to ensure that they are properly installed and secured. Screens that are not securely fastened in place can shift or become dislodged during operation, leading to leaks or other issues. To prevent this, it is important to follow the manufacturer’s installation instructions carefully and regularly check that the screen is securely in place.

In addition to regular cleaning and inspection, it is also important to monitor the performance of the screen over time. By keeping track of key performance metrics, such as flow rate and pressure drop, it is possible to identify any changes or issues that may indicate a problem with the screen. By monitoring these metrics regularly, any issues can be addressed promptly, ensuring that the screen continues to operate at peak efficiency.

Finally, it is important to follow the manufacturer’s recommended maintenance schedule for the screen. This may include periodic replacement of certain components, such as seals or gaskets, to ensure that the screen continues to operate effectively. By following the manufacturer’s recommendations, it is possible to extend the lifespan of the screen and prevent costly repairs or replacements down the line.

In conclusion, high-performance 75 micron screens are essential components in many industrial processes that require precise filtration. To ensure optimal performance, it is important to follow a few key maintenance tips, including regular cleaning, inspection, and monitoring of performance metrics. By following these tips, it is possible to extend the lifespan of the screen and ensure that it continues to operate at peak efficiency.