Table of Contents

Benefits of Using High-Performance 10 Micron Mesh Screens for Ultra-Fine Filtration

High-performance 10 micron mesh screens are essential for achieving ultra-fine filtration in various industries. These screens are designed to effectively remove particles as small as 10 microns, ensuring that the final product is free from contaminants and impurities. There are several benefits to using high-performance 10 micron mesh screens for ultra-fine filtration.

One of the primary benefits of using high-performance 10 micron mesh screens is their ability to provide superior filtration efficiency. These screens are specifically designed to capture particles that are 10 microns in size or larger, ensuring that even the smallest contaminants are removed from the liquid or gas being filtered. This level of filtration efficiency is crucial in industries where product purity is of utmost importance, such as pharmaceuticals, food and beverage, and electronics manufacturing.

In addition to their superior filtration efficiency, high-performance 10 micron mesh screens also offer excellent durability and longevity. These screens are typically made from high-quality materials that are resistant to corrosion, abrasion, and other forms of wear and tear. This means that they can withstand the rigors of continuous use without losing their effectiveness, making them a cost-effective filtration solution in the long run.

Furthermore, high-performance 10 micron mesh screens are easy to clean and maintain, which helps to minimize downtime and ensure consistent filtration performance. These screens can be easily removed, cleaned, and reinstalled, allowing for quick and efficient maintenance procedures. This is especially important in industries where downtime can result in significant financial losses, as it helps to keep production running smoothly and efficiently.

Another key benefit of using high-performance 10 micron mesh screens is their versatility. These screens can be customized to meet the specific filtration requirements of different industries and applications. Whether you need a screen with a specific mesh size, material composition, or configuration, high-performance 10 micron mesh screens can be tailored to suit your needs. This level of customization ensures that you get the most effective filtration solution for your particular application.

Additionally, high-performance 10 micron mesh screens are environmentally friendly, as they help to reduce waste and minimize the need for disposable filtration products. By using durable, long-lasting screens that can be easily cleaned and reused, you can significantly reduce your environmental footprint and contribute to a more sustainable future.

In conclusion, high-performance 10 micron mesh screens offer a wide range of benefits for industries that require ultra-fine filtration. From superior filtration efficiency and durability to easy maintenance and customization options, these screens provide a cost-effective and environmentally friendly solution for achieving high-quality filtration results. If you are looking for a reliable and efficient filtration solution for your business, consider investing in high-performance 10 micron mesh screens.

How to Choose the Right High-Performance 10 micron mesh screen for Your Filtration Needs

When it comes to ultra-fine filtration, high-performance 10 micron mesh screens are essential for achieving optimal results. These screens are designed to capture even the smallest particles, ensuring that your filtration system operates efficiently and effectively. However, with so many options available on the market, choosing the right high-performance 10 micron mesh screen for your specific needs can be a daunting task. In this article, we will discuss some key factors to consider when selecting a high-performance 10 micron mesh screen for your filtration system.

One of the most important factors to consider when choosing a high-performance 10 micron mesh screen is the material from which it is made. Stainless steel is a popular choice for mesh screens due to its durability and resistance to corrosion. Additionally, stainless steel mesh screens are easy to clean and maintain, making them ideal for use in industrial applications where frequent cleaning is necessary. Other materials, such as nylon and polyester, are also commonly used for mesh screens and offer their own unique benefits. nylon mesh screens are lightweight and flexible, while polyester mesh screens are resistant to chemicals and abrasion.

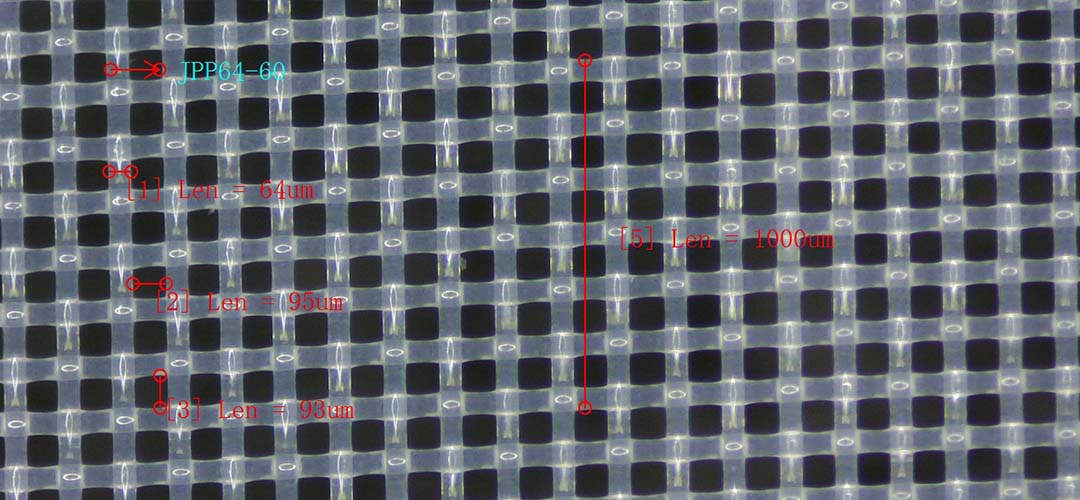

Another important factor to consider when selecting a high-performance 10 micron mesh screen is the weave pattern. The weave pattern of a mesh screen refers to the way in which the wires are interlaced to form the mesh. Common weave patterns include plain weave, twill weave, and Dutch weave. Each weave pattern offers its own unique benefits in terms of filtration efficiency and strength. For example, plain weave mesh screens are simple and cost-effective, while Dutch weave mesh screens offer superior filtration capabilities due to their tight weave structure.

In addition to material and weave pattern, it is also important to consider the size and shape of the mesh screen when choosing a high-performance 10 micron mesh screen for your filtration system. The size of the mesh screen refers to the number of openings per inch, with a higher number indicating a finer mesh. A 10 micron mesh screen is ideal for capturing small particles, making it suitable for applications where ultra-fine filtration is required. The shape of the mesh screen can also impact its performance, with options such as square, rectangular, and circular mesh screens available to suit different filtration needs.

When selecting a high-performance 10 micron mesh screen, it is important to consider the specific requirements of your filtration system. Factors such as flow rate, pressure, and temperature can all impact the performance of a mesh screen, so it is essential to choose a screen that is designed to withstand these conditions. Additionally, considering the type of particles that need to be filtered can help determine the best mesh screen for your needs. For example, if you are filtering abrasive particles, a mesh screen with a higher tensile strength may be required to prevent damage.

In conclusion, high-performance 10 micron mesh screens are essential for achieving ultra-fine filtration in a variety of applications. By considering factors such as material, weave pattern, size, and shape, you can choose the right mesh screen for your specific filtration needs. Whether you are filtering water, chemicals, or other substances, a high-performance 10 micron mesh screen can help ensure that your filtration system operates efficiently and effectively.

Maintenance Tips for Ensuring Optimal Performance of High-Performance 10 Micron Mesh Screens

High-performance 10 micron mesh screens are essential components in many industrial filtration systems. These screens are designed to capture particles as small as 10 microns, making them ideal for applications that require ultra-fine filtration. However, in order to ensure optimal performance, it is important to properly maintain these screens.

One of the key maintenance tips for high-performance 10 micron mesh screens is regular cleaning. Over time, particles can build up on the surface of the screen, reducing its effectiveness. To prevent this buildup, it is important to clean the screen on a regular basis. This can be done by using a soft brush or cloth to gently remove any debris from the surface of the screen. In some cases, it may be necessary to use a mild detergent to help loosen stubborn particles.

In addition to regular cleaning, it is also important to inspect the screen for any signs of damage. Even small tears or holes in the mesh can significantly reduce the screen’s effectiveness. If any damage is found, it is important to repair or replace the screen as soon as possible to prevent further issues.

Another important maintenance tip for high-performance 10 micron mesh screens is to ensure proper installation. The screen should be securely fastened in place to prevent it from shifting or becoming dislodged during operation. Additionally, it is important to ensure that the screen is properly aligned with the flow of the filtration system to maximize its effectiveness.

Proper maintenance of high-performance 10 micron mesh screens also includes monitoring the pressure differential across the screen. A significant increase in pressure drop may indicate that the screen is becoming clogged and needs to be cleaned or replaced. Monitoring the pressure drop on a regular basis can help prevent issues before they become more serious.

In addition to these maintenance tips, it is also important to consider the environment in which the screen is operating. High temperatures, corrosive chemicals, and abrasive materials can all impact the performance of the screen. It is important to choose a screen material that is compatible with the specific conditions of the application to ensure optimal performance.

Overall, proper maintenance of high-performance 10 micron mesh screens is essential for ensuring optimal filtration performance. By following these maintenance tips, you can help extend the life of your screens and maximize their effectiveness. Regular cleaning, inspection for damage, proper installation, monitoring pressure differentials, and considering the operating environment are all key factors in maintaining high-performance 10 micron mesh screens. By taking the time to properly maintain your screens, you can ensure that they continue to provide reliable filtration for your industrial applications.