Table of Contents

Benefits of Using Flexible and Durable 40 Micron Screens for Filtration

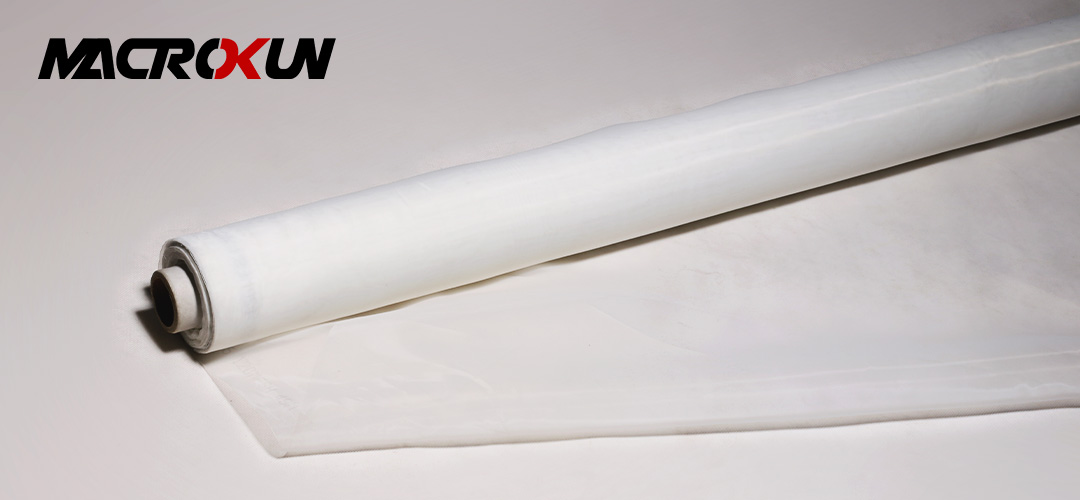

When it comes to filtration, having the right equipment is crucial to ensuring optimal performance and efficiency. One key component of any filtration system is the screen used to separate particles from liquids or gases. In recent years, flexible and durable 40 micron screens have emerged as a popular choice for a wide range of filtration applications. These screens offer a number of benefits that make them ideal for use in various industries.

One of the primary advantages of flexible and durable 40 micron screens is their versatility. These screens can be used in a wide range of applications, from industrial filtration to water treatment. Their flexibility allows them to conform to different shapes and sizes, making them suitable for use in a variety of filtration systems. Whether you need to filter out large particles or fine contaminants, a 40 micron screen can provide the level of filtration you need.

In addition to their versatility, flexible and durable 40 micron screens are also known for their durability. Made from high-quality materials, these screens are designed to withstand the rigors of continuous use in demanding environments. This durability ensures that the screens will last longer and require less frequent replacement, saving you time and money in the long run. With a 40 micron screen, you can trust that your filtration system will continue to perform at its best for years to come.

Another benefit of using flexible and durable 40 micron screens is their efficiency. These screens are designed to provide high levels of filtration while allowing for optimal flow rates. This means that you can achieve the level of filtration you need without sacrificing the speed at which liquids or gases pass through the system. With a 40 micron screen, you can ensure that your filtration system operates at peak efficiency, helping you to maximize productivity and minimize downtime.

Furthermore, flexible and durable 40 micron screens are easy to clean and maintain. Their design allows for quick and simple removal of trapped particles, making it easy to keep the screens in top condition. Regular cleaning and maintenance of the screens can help to prolong their lifespan and ensure that they continue to perform effectively over time. With a 40 micron screen, you can enjoy the peace of mind that comes with knowing your filtration system is well-maintained and operating at its best.

In conclusion, flexible and durable 40 micron screens offer a range of benefits that make them an excellent choice for filtration applications. Their versatility, durability, efficiency, and ease of maintenance make them ideal for use in a variety of industries. Whether you need to filter out large particles or fine contaminants, a 40 micron screen can provide the level of filtration you need while ensuring optimal performance and longevity. Consider incorporating flexible and durable 40 micron screens into your filtration system to experience the many benefits they have to offer.

Applications of Versatile Filtration with 40 Micron Screens

When it comes to filtration, having the right tools for the job is essential. One such tool that has gained popularity in various industries is the 40-micron screen. These screens are known for their flexibility and durability, making them ideal for a wide range of filtration applications.

One of the key advantages of using 40-micron screens is their versatility. These screens can be used in a variety of industries, including food and beverage, pharmaceuticals, chemicals, and more. Their ability to filter out particles as small as 40 microns makes them suitable for a wide range of applications, from removing impurities in liquids to separating solids from liquids.

In the food and beverage industry, 40-micron screens are commonly used to filter out impurities in liquids such as juices, wines, and dairy products. These screens can effectively remove particles such as pulp, seeds, and sediment, ensuring that the final product is clean and free of contaminants. Additionally, the flexibility of these screens allows for easy installation and maintenance, making them a cost-effective solution for food and beverage manufacturers.

In the pharmaceutical industry, 40-micron screens play a crucial role in ensuring the purity of drugs and medications. These screens can filter out bacteria, viruses, and other contaminants, ensuring that the final product meets strict quality standards. The durability of these screens also makes them ideal for use in sterile environments, where cleanliness and hygiene are paramount.

In the chemical industry, 40-micron screens are used to separate solids from liquids in various processes, such as wastewater treatment and chemical production. These screens can effectively remove particles such as rust, scale, and other impurities, ensuring that the final product is of high quality. The flexibility of these screens allows for easy customization to meet the specific needs of each application, making them a versatile solution for chemical manufacturers.

Overall, the applications of 40-micron screens are vast and varied, making them a valuable tool for filtration in a wide range of industries. Their flexibility and durability make them ideal for use in demanding environments, where reliability and performance are essential. Whether filtering out impurities in food and beverage production, ensuring the purity of pharmaceuticals, or separating solids from liquids in chemical processes, 40-micron screens are a versatile and reliable solution for all filtration needs.

In conclusion, 40-micron screens are a valuable tool for versatile filtration applications. Their flexibility and durability make them ideal for use in a wide range of industries, from food and beverage to pharmaceuticals and chemicals. Whether removing impurities in liquids, ensuring the purity of medications, or separating solids from liquids, these screens are a reliable and cost-effective solution for all filtration needs. With their ability to filter out particles as small as 40 microns, 40-micron screens are a versatile and essential tool for any filtration system.

Maintenance Tips for Extending the Lifespan of Flexible 40 Micron Screens

When it comes to filtration systems, having the right screen in place is crucial for ensuring optimal performance. Flexible 40 micron screens are a popular choice for many industries due to their versatility and durability. These screens are capable of filtering out particles as small as 40 microns, making them ideal for a wide range of applications. However, in order to maximize the lifespan of these screens and maintain their effectiveness, proper maintenance is essential.

One of the key maintenance tips for extending the lifespan of flexible 40 micron screens is regular cleaning. Over time, debris and particles can build up on the surface of the screen, reducing its efficiency and potentially causing damage. By regularly cleaning the screen, you can prevent this buildup and ensure that it continues to function effectively. This can be done using a soft brush or cloth to gently remove any debris, being careful not to damage the screen in the process.

In addition to regular cleaning, it is also important to inspect the screen for any signs of wear or damage. Flexible 40 micron screens are designed to be durable, but they are not indestructible. By regularly inspecting the screen for tears, holes, or other damage, you can catch any issues early on and prevent them from worsening. If any damage is found, it is important to address it promptly to prevent further damage and ensure the continued effectiveness of the screen.

Another important maintenance tip for flexible 40 micron screens is to ensure that they are properly installed and secured. Improper installation can lead to the screen becoming loose or misaligned, which can reduce its effectiveness and potentially cause damage. By ensuring that the screen is securely in place and properly aligned, you can prevent these issues and ensure that it continues to function as intended.

In addition to these maintenance tips, it is also important to consider the environment in which the screen is being used. Flexible 40 micron screens are designed to be versatile and durable, but they may be more susceptible to certain environmental factors. For example, exposure to harsh chemicals or extreme temperatures can cause damage to the screen over time. By taking steps to protect the screen from these factors, such as using protective coatings or installing it in a controlled environment, you can extend its lifespan and ensure that it continues to perform effectively.

Overall, flexible 40 micron screens are a versatile and durable filtration option that can be used in a wide range of applications. By following these maintenance tips, you can extend the lifespan of these screens and ensure that they continue to function effectively. Regular cleaning, inspection, proper installation, and environmental considerations are all key factors in maintaining the effectiveness of flexible 40 micron screens. By taking these steps, you can maximize the lifespan of your screens and ensure that they continue to meet your filtration needs for years to come.