Table of Contents

Applications of nylon mesh Sieves in Water Filtration

Nylon mesh has long been a popular choice for sieves in filtration due to its versatility and durability. In the realm of water filtration, nylon mesh sieves have proven to be highly effective in removing impurities and ensuring clean, safe drinking water. The applications of nylon mesh sieves in water filtration are vast, ranging from industrial settings to household use.

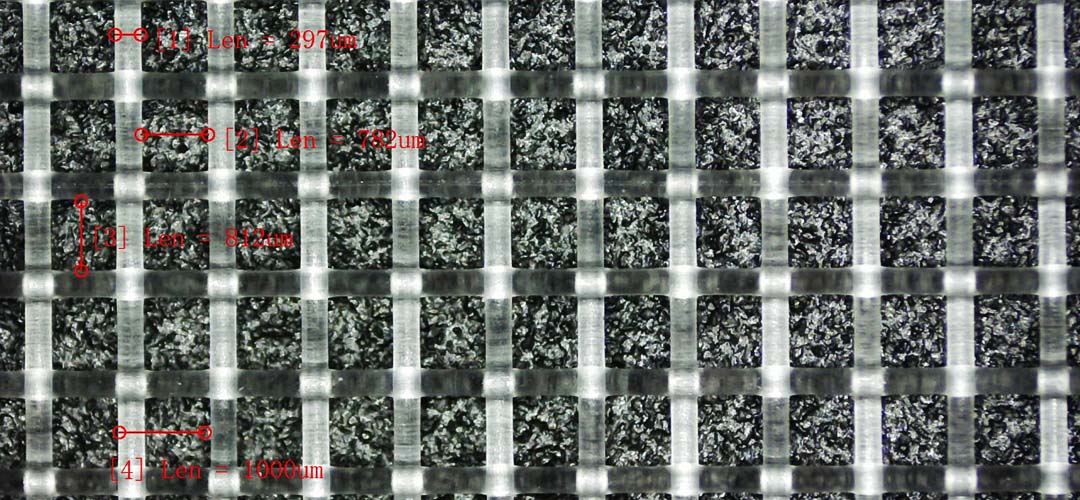

One of the key advantages of using nylon mesh sieves in water filtration is their ability to effectively trap particles of various sizes. The fine mesh of nylon sieves can capture even the smallest impurities, ensuring that the water passing through is free from contaminants. This makes nylon mesh sieves ideal for use in industries where water quality is of utmost importance, such as pharmaceutical manufacturing or food processing.

Additionally, nylon mesh sieves are highly durable and resistant to corrosion, making them a cost-effective choice for long-term use. Unlike other materials that may degrade over time, nylon mesh sieves can withstand harsh conditions and continue to perform at optimal levels. This durability makes nylon mesh sieves a reliable option for continuous filtration processes, where consistent performance is essential.

In addition to their effectiveness and durability, nylon mesh sieves are also easy to clean and maintain. The smooth surface of nylon mesh makes it easy to remove trapped particles and debris, ensuring that the sieve remains in top condition. This ease of maintenance is particularly beneficial in industries where frequent cleaning is necessary to prevent clogging and maintain efficiency.

Furthermore, nylon mesh sieves can be customized to meet specific filtration requirements. With a wide range of mesh sizes available, nylon sieves can be tailored to capture particles of different sizes, making them suitable for a variety of filtration applications. Whether filtering out large debris or capturing microscopic contaminants, nylon mesh sieves can be designed to meet the unique needs of each filtration process.

The versatility of nylon mesh sieves extends beyond industrial settings to everyday use in households. Nylon mesh sieves are commonly used in water filtration systems at home, providing families with clean, safe drinking water. Whether attached to a faucet or incorporated into a pitcher filter, nylon mesh sieves play a crucial role in ensuring that tap water is free from impurities.

In conclusion, the applications of nylon mesh sieves in water filtration are vast and varied. From industrial settings to household use, nylon mesh sieves offer a reliable and effective solution for removing impurities and ensuring clean water. With their durability, ease of maintenance, and customizable options, nylon mesh sieves are a versatile choice for any filtration process. Whether filtering out large particles or capturing microscopic contaminants, nylon mesh sieves are a valuable tool in maintaining water quality and safety.

Advantages of Using Nylon Mesh for Food Processing Sieves

Nylon mesh has become a popular choice for sieves in food processing due to its versatility and effectiveness in filtration. This durable material offers a number of advantages that make it ideal for use in a variety of food processing applications.

One of the key advantages of using nylon mesh for food processing sieves is its strength and durability. Nylon is a synthetic material that is known for its high tensile strength, making it resistant to tearing and damage. This means that nylon mesh sieves can withstand the rigors of food processing without breaking or becoming damaged, ensuring that they can be used repeatedly without needing to be replaced.

In addition to its strength, nylon mesh is also resistant to corrosion and chemical damage. This makes it an ideal material for use in food processing, where exposure to acidic or caustic substances is common. Nylon mesh sieves can be safely used with a wide range of food products without the risk of contamination or degradation, making them a reliable choice for food processing applications.

Another advantage of using nylon mesh for food processing sieves is its flexibility. Nylon mesh can be easily molded and shaped to fit a variety of sieve sizes and shapes, making it a versatile option for use in different types of food processing equipment. This flexibility allows for customization and adaptation to specific processing needs, ensuring that nylon mesh sieves can be tailored to meet the requirements of any food processing operation.

Nylon mesh sieves are also easy to clean and maintain, making them a practical choice for food processing facilities. Nylon is a non-porous material that resists the buildup of bacteria and other contaminants, making it easy to clean and sanitize. This helps to ensure the safety and quality of food products processed using nylon mesh sieves, while also reducing the risk of cross-contamination.

Furthermore, nylon mesh is a cost-effective option for food processing sieves. Nylon is a relatively inexpensive material compared to other types of mesh, making it a budget-friendly choice for food processing facilities looking to save on costs. Despite its affordability, nylon mesh offers high performance and durability, making it a cost-effective investment for food processing operations.

Overall, the versatility of nylon mesh for sieves in food processing makes it an excellent choice for a wide range of applications. Its strength, durability, resistance to corrosion, flexibility, ease of cleaning, and cost-effectiveness make it a practical and reliable option for food processing facilities looking to improve their filtration processes. By choosing nylon mesh sieves, food processors can ensure the safety, quality, and efficiency of their operations, while also saving on costs in the long run.

Comparing Nylon Mesh with Other Materials in Filtration Systems

Nylon mesh has become a popular choice for sieves in filtration systems due to its versatility and effectiveness. When compared to other materials such as stainless steel, brass, and polyester, nylon mesh offers unique advantages that make it a preferred option for many industries.

One of the key benefits of nylon mesh is its flexibility. Nylon is a synthetic material that can be easily molded into different shapes and sizes, making it ideal for custom filtration applications. This flexibility allows for the creation of sieves that can fit specific filtration needs, whether it be for large-scale industrial processes or small laboratory experiments.

In addition to its flexibility, nylon mesh is also known for its durability. Nylon is a strong material that can withstand high temperatures and harsh chemicals, making it suitable for a wide range of filtration tasks. Unlike other materials that may corrode or degrade over time, nylon mesh maintains its integrity and effectiveness, ensuring consistent filtration results.

Another advantage of nylon mesh is its resistance to abrasion. Nylon is a tough material that can withstand wear and tear, making it ideal for continuous use in filtration systems. This resistance to abrasion ensures that the mesh remains intact and effective, even after prolonged exposure to harsh conditions.

Furthermore, nylon mesh is easy to clean and maintain. Unlike other materials that may require special cleaning procedures or maintenance, nylon mesh can be easily washed with water and mild detergent. This ease of maintenance makes nylon mesh a cost-effective option for filtration systems, as it reduces the need for frequent replacements or repairs.

When compared to stainless steel, brass, and polyester, nylon mesh offers unique advantages that make it a versatile choice for sieves in filtration systems. Stainless steel is known for its strength and durability, but it can be heavy and expensive. Brass is a durable material, but it may corrode over time. Polyester is a lightweight material, but it may not be as durable as nylon.

In conclusion, nylon mesh is a versatile and effective material for sieves in filtration systems. Its flexibility, durability, resistance to abrasion, and ease of maintenance make it a preferred option for many industries. When compared to other materials such as stainless steel, brass, and polyester, nylon mesh offers unique advantages that make it a reliable choice for a wide range of filtration applications. Whether used in large-scale industrial processes or small laboratory experiments, nylon mesh continues to prove its worth as a valuable tool in the field of filtration.