Table of Contents

Benefits of Using nylon mesh Material in Filtration Systems

Nylon mesh material has long been a popular choice for filtration systems due to its durability and effectiveness. In this article, we will explore the benefits of using nylon mesh material in filtration systems and why it is a preferred choice for many industries.

One of the key advantages of nylon mesh material is its durability. Nylon is a synthetic polymer that is known for its strength and resilience, making it an ideal material for filtration applications. Nylon mesh can withstand high temperatures, harsh chemicals, and abrasive materials without losing its shape or effectiveness. This durability ensures that the filtration system will continue to perform efficiently over an extended period of time, reducing the need for frequent replacements and maintenance.

In addition to its durability, nylon mesh material is also highly effective at capturing and retaining particles of various sizes. The fine mesh structure of nylon allows for efficient filtration of even the smallest particles, ensuring that the filtered material is free of contaminants. This makes nylon mesh material an excellent choice for industries that require precise filtration, such as pharmaceuticals, food and beverage, and electronics manufacturing.

Furthermore, nylon mesh material is easy to clean and maintain, making it a cost-effective option for filtration systems. Unlike other materials that may require specialized cleaning procedures or replacement filters, nylon mesh can be easily cleaned with water or mild detergent, allowing for quick and efficient maintenance. This not only saves time and money but also ensures that the filtration system remains in optimal condition for longer periods.

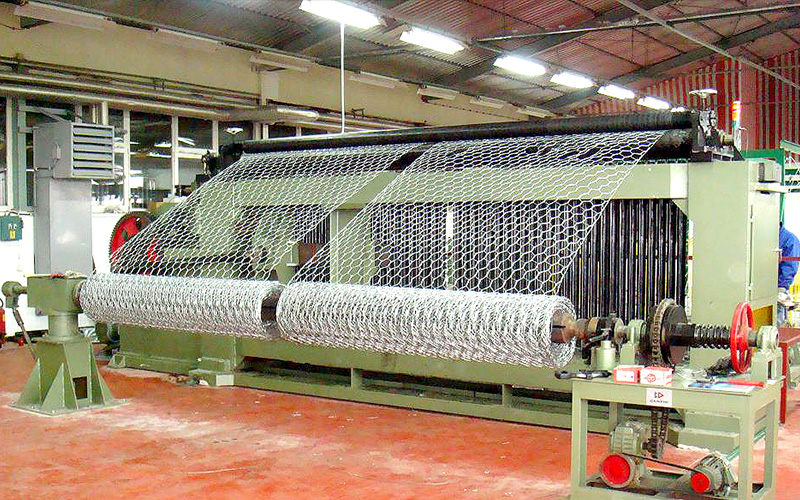

Another benefit of using nylon mesh material in filtration systems is its versatility. Nylon mesh can be customized to meet specific filtration requirements, such as different mesh sizes, thicknesses, and configurations. This flexibility allows for the creation of tailored filtration solutions that can effectively remove contaminants and impurities from a wide range of materials. Whether filtering liquids, gases, or solids, nylon mesh material can be adapted to suit the unique needs of each application.

Moreover, nylon mesh material is environmentally friendly, as it can be recycled and reused multiple times without losing its effectiveness. This sustainability factor is increasingly important for businesses looking to reduce their environmental impact and adhere to strict regulations regarding waste management. By choosing nylon mesh material for filtration systems, companies can not only improve their operational efficiency but also demonstrate their commitment to sustainability and responsible business practices.

In conclusion, the durability, effectiveness, ease of maintenance, versatility, and sustainability of nylon mesh material make it an excellent choice for filtration systems in a variety of industries. By utilizing nylon mesh material in their filtration systems, businesses can benefit from improved performance, reduced maintenance costs, and enhanced environmental responsibility. As technology continues to advance, nylon mesh material will likely remain a preferred option for filtration applications, providing reliable and efficient solutions for years to come.

Testing the Strength and Longevity of Nylon Mesh Filters

Nylon mesh filters are commonly used in various industries for filtration purposes due to their durability and effectiveness in capturing particles. However, it is essential to understand the longevity and strength of these filters to ensure optimal performance over time. In this article, we will explore the durability of nylon mesh material in filtration and discuss the importance of testing the strength and longevity of these filters.

Nylon mesh filters are known for their high tensile strength and resistance to abrasion, making them ideal for filtering applications where durability is crucial. The material is also resistant to chemicals and can withstand high temperatures, making it suitable for a wide range of industrial processes. However, despite these qualities, it is essential to test the strength and longevity of nylon mesh filters to ensure they can withstand the rigors of continuous use.

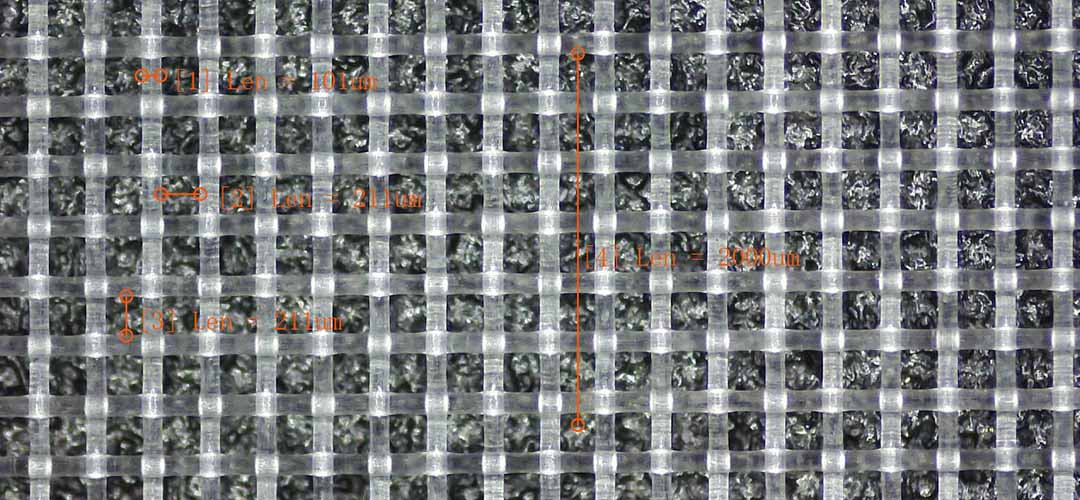

One of the key factors in determining the durability of nylon mesh filters is the pore size of the material. The size of the pores in the mesh determines the particles that can be captured, with smaller pores being more effective at filtering out fine particles. Testing the pore size of nylon mesh filters is essential to ensure they meet the required specifications for the application.

Another important factor to consider when testing the durability of nylon mesh filters is the flow rate of the material. The flow rate of a filter determines how quickly it can process fluids or gases, and testing the flow rate of nylon mesh filters is crucial to ensure they can handle the required volume of material without clogging or becoming damaged.

In addition to pore size and flow rate, the material composition of nylon mesh filters also plays a significant role in determining their durability. Nylon is known for its strength and flexibility, but testing the material composition of filters is essential to ensure they can withstand the conditions they will be exposed to in real-world applications.

To test the strength and longevity of nylon mesh filters, various methods can be used, including pressure testing, abrasion testing, and chemical resistance testing. Pressure testing involves subjecting the filter to high pressures to determine its ability to withstand the forces it will be exposed to during filtration. Abrasion testing involves rubbing the filter against a rough surface to simulate wear and tear over time, while chemical resistance testing involves exposing the filter to various chemicals to determine its resistance to corrosion.

By testing the strength and longevity of nylon mesh filters, manufacturers can ensure their products meet the required specifications for filtration applications. This not only ensures the quality and performance of the filters but also helps to prevent costly downtime and maintenance issues in industrial processes.

In conclusion, the durability of nylon mesh material in filtration is essential for ensuring optimal performance and longevity of filters in various industries. By testing the strength and longevity of these filters, manufacturers can guarantee their products meet the required specifications for filtration applications, ultimately leading to improved efficiency and reliability in industrial processes.

Comparing Nylon Mesh Filters to Other Filtration Materials

Nylon mesh material has long been a popular choice for filtration applications due to its durability and versatility. In this article, we will explore the durability of nylon mesh material in filtration and compare it to other filtration materials on the market.

Nylon mesh filters are known for their strength and resilience, making them ideal for a wide range of filtration tasks. The material is resistant to tears and punctures, ensuring that it can withstand the rigors of filtration processes without compromising its effectiveness. This durability is a key factor in the popularity of nylon mesh filters, as it allows them to be used in demanding industrial applications where other materials may fail.

One of the main advantages of nylon mesh filters is their ability to maintain their integrity over time. Unlike some other filtration materials that can degrade or break down with prolonged use, nylon mesh filters are designed to last. This longevity is a major selling point for businesses looking to minimize downtime and reduce maintenance costs associated with filtration systems.

In addition to their durability, nylon mesh filters are also highly versatile. The material can be easily customized to meet specific filtration requirements, making it suitable for a wide range of applications. Whether filtering liquids, gases, or solids, nylon mesh filters can be tailored to provide the optimal level of filtration for each unique situation.

When compared to other filtration materials, nylon mesh filters stand out for their durability and longevity. Materials such as paper or cloth filters may be cheaper initially, but they often need to be replaced more frequently due to their lower durability. This can result in higher long-term costs and increased downtime for businesses relying on filtration systems.

Another advantage of nylon mesh filters is their resistance to chemicals and high temperatures. The material can withstand exposure to a wide range of chemicals without degrading, making it suitable for use in harsh industrial environments. Additionally, nylon mesh filters can be used in high-temperature applications without losing their effectiveness, providing businesses with a reliable filtration solution for demanding processes.

In conclusion, the durability of nylon mesh material in filtration makes it a top choice for businesses looking for a reliable and long-lasting filtration solution. Compared to other filtration materials, nylon mesh filters offer superior strength and resilience, ensuring that they can withstand the rigors of industrial applications without compromising their effectiveness. With their versatility and resistance to chemicals and high temperatures, nylon mesh filters are a cost-effective and efficient choice for businesses seeking a durable filtration solution.