Table of Contents

Benefits of Using Micron Filter Mesh in Industrial Filtration Processes

Micron filter mesh is a crucial component in industrial filtration processes, providing a reliable and efficient way to separate particles of different sizes from liquids and gases. With a wide range of micron filter mesh options available on the market, it is essential for businesses to explore the different types to find the best fit for their specific applications.

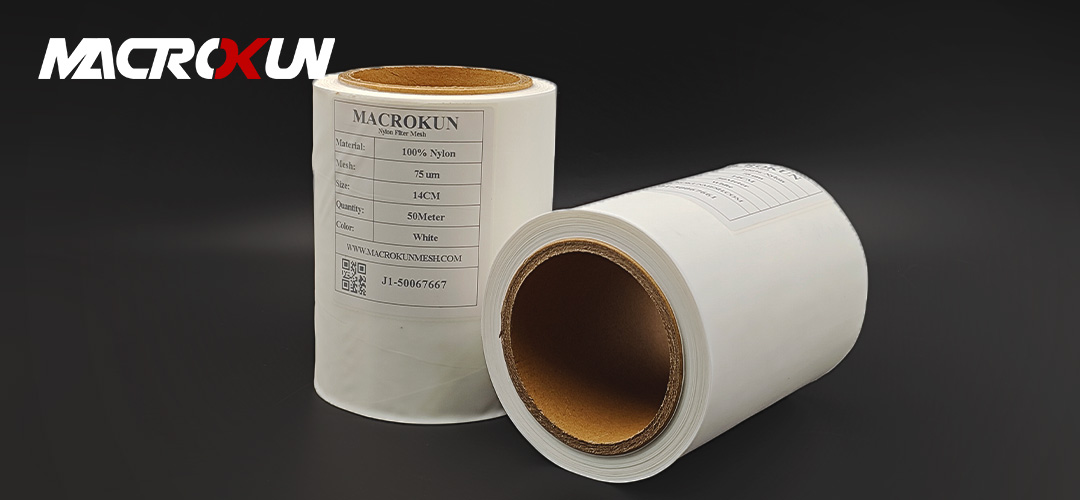

One of the key benefits of using micron filter mesh is its versatility. Micron filter mesh comes in various materials, such as stainless steel, nylon, and polyester, each offering unique properties that make them suitable for different applications. Stainless steel mesh, for example, is known for its durability and resistance to corrosion, making it ideal for applications where the filter mesh is exposed to harsh chemicals or high temperatures. On the other hand, nylon mesh is lightweight and flexible, making it a popular choice for applications that require a more delicate touch.

In addition to material options, micron filter mesh also comes in a range of mesh sizes, with each size offering a different level of filtration. The mesh size refers to the number of openings per linear inch, with smaller mesh sizes providing finer filtration and larger mesh sizes offering coarser filtration. By selecting the right mesh size, businesses can achieve the desired level of filtration for their specific application, ensuring that only particles of a certain size are allowed to pass through the filter mesh.

Another benefit of using micron filter mesh is its efficiency in removing contaminants from liquids and gases. The fine openings in the mesh trap particles of various sizes, ranging from large debris to microscopic contaminants, ensuring that the filtered liquid or gas is free from impurities. This level of filtration is essential in industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest particles can have a significant impact on product quality.

Furthermore, micron filter mesh is easy to clean and maintain, making it a cost-effective solution for businesses. Depending on the application, the filter mesh can be cleaned using methods such as backwashing, ultrasonic cleaning, or chemical cleaning, ensuring that it remains in optimal condition for extended periods. This longevity and ease of maintenance make micron filter mesh a reliable and sustainable choice for industrial filtration processes.

In conclusion, exploring the different micron filter mesh options available on the market can help businesses find the best fit for their specific applications. With a wide range of material options and mesh sizes to choose from, businesses can customize their filtration process to achieve the desired level of filtration efficiency. By investing in high-quality micron filter mesh, businesses can improve product quality, reduce downtime, and increase overall efficiency in their industrial filtration processes.

How to Choose the Right Micron Filter Mesh for Specific Applications

When it comes to choosing the right micron filter mesh for specific applications, it is important to consider the various options available in the market. Micron filter mesh is a versatile tool that can be used in a wide range of industries, from food and beverage to pharmaceuticals and chemicals. Understanding the different types of micron filter mesh and their applications can help you make an informed decision when selecting the right one for your needs.

One of the key factors to consider when choosing a micron filter mesh is the size of the particles you need to filter. Micron filter mesh is available in a range of sizes, from as small as 5 microns to as large as 1000 microns. The smaller the micron size, the finer the particles that can be filtered out. For applications that require a high level of filtration, such as in the pharmaceutical or semiconductor industries, a smaller micron size is typically preferred.

Another important consideration when choosing a micron filter mesh is the material it is made from. Micron filter mesh can be made from a variety of materials, including stainless steel, nylon, and polyester. Each material has its own unique properties that make it suitable for different applications. Stainless steel mesh, for example, is durable and resistant to corrosion, making it ideal for use in harsh environments. Nylon mesh, on the other hand, is lightweight and flexible, making it a good choice for applications that require a high level of flexibility.

In addition to size and material, the weave pattern of the micron filter mesh is also an important factor to consider. The weave pattern determines the strength and durability of the mesh, as well as its ability to filter out particles of a certain size. Common weave patterns include plain weave, twill weave, and Dutch weave. Plain weave is the most basic weave pattern, with each warp wire passing over and under each weft wire in a simple crisscross pattern. Twill weave, on the other hand, is a more complex weave pattern that creates a diagonal pattern on the surface of the mesh. Dutch weave is a tight weave pattern that is ideal for applications that require a high level of filtration.

When choosing a micron filter mesh, it is important to consider the specific requirements of your application. For example, if you need to filter out very fine particles, a mesh with a smaller micron size and a tight weave pattern may be required. On the other hand, if you need to filter out larger particles, a mesh with a larger micron size and a looser weave pattern may be more suitable. By understanding the different options available and their respective properties, you can choose the right micron filter mesh for your specific needs.

In conclusion, exploring the different micron filter mesh options available in the market can help you make an informed decision when choosing the right one for your specific application. By considering factors such as size, material, and weave pattern, you can select a micron filter mesh that meets your filtration requirements and provides optimal performance. Whether you are in the food and beverage industry, pharmaceuticals, or chemicals, there is a micron filter mesh option that is suitable for your needs.

Case Studies Highlighting Successful Implementation of Micron Filter Mesh in Various Industries

Micron filter mesh is a critical component in many industries, providing a means to separate particles of different sizes and shapes. The versatility of micron filter mesh makes it an essential tool for a wide range of applications, from food and beverage processing to pharmaceutical manufacturing. In this article, we will explore different micron filter mesh options and highlight successful case studies of their implementation in various industries.

One of the most common uses of micron filter mesh is in the food and beverage industry. In this industry, the quality of the final product is of utmost importance, and micron filter mesh plays a crucial role in ensuring that only the finest particles make it through the filtration process. By using micron filter mesh with the appropriate pore size, food and beverage manufacturers can remove impurities and contaminants, resulting in a cleaner and safer product for consumers.

In a recent case study, a leading beverage company implemented micron filter mesh in their production process to improve the quality of their products. By using a fine mesh with a pore size of 5 microns, the company was able to remove unwanted particles and ensure that their beverages met the highest standards of purity. As a result, the company saw an increase in customer satisfaction and a boost in sales.

Another industry that benefits from the use of micron filter mesh is the pharmaceutical industry. In pharmaceutical manufacturing, the need for precision and accuracy is paramount, and micron filter mesh helps to achieve this by separating particles based on their size. By using micron filter mesh with a pore size of 1 micron or less, pharmaceutical companies can remove even the smallest impurities from their products, ensuring that they meet the strictest quality standards.

In a recent case study, a pharmaceutical company implemented micron filter mesh in their production process to improve the purity of their medications. By using a ultra-fine mesh with a pore size of 0.2 microns, the company was able to remove microscopic contaminants and ensure that their medications were safe and effective for patients. This led to an increase in customer trust and loyalty, as well as a decrease in product recalls due to contamination.

In addition to the food and beverage and pharmaceutical industries, micron filter mesh is also used in a variety of other applications, such as water treatment, oil and gas refining, and chemical processing. In each of these industries, the use of micron filter mesh helps to improve the quality and efficiency of production processes, leading to cost savings and increased productivity.

Overall, micron filter mesh is a versatile tool that can be used in a wide range of industries to improve product quality and safety. By choosing the right mesh size for the specific application, companies can achieve optimal results and gain a competitive edge in the market. The case studies highlighted in this article demonstrate the successful implementation of micron filter mesh in various industries, showcasing the benefits of this essential filtration technology.