Table of Contents

Benefits of Using 300 Micron Strainers in Industrial Settings

Efficient 300 Micron Strainers for Industrial and Domestic Use

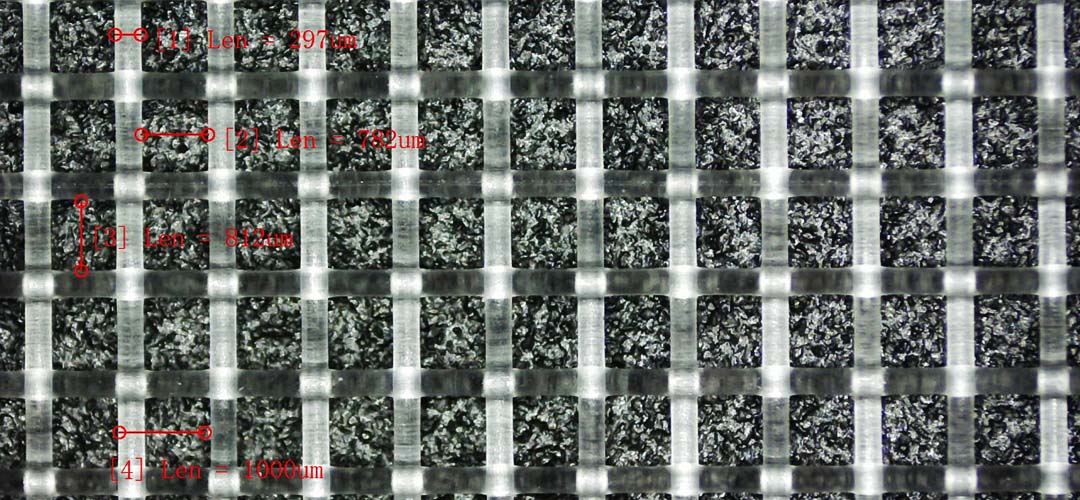

When it comes to industrial settings, having the right equipment is crucial for ensuring smooth operations and maintaining high levels of efficiency. One such piece of equipment that is essential for many industries is the 300 micron strainer. These strainers are designed to filter out particles that are 300 microns or larger in size, making them ideal for a wide range of applications.

One of the key benefits of using 300 micron strainers in industrial settings is their ability to effectively remove large particles from liquids. This is important in industries such as food and beverage production, where the presence of contaminants can compromise the quality and safety of the final product. By using a 300 micron strainer, these industries can ensure that their products meet the highest standards of quality and purity.

Another benefit of using 300 micron strainers in industrial settings is their efficiency. These strainers are designed to handle large volumes of liquid, making them ideal for use in industrial processes that require continuous filtration. This can help to streamline operations and reduce downtime, ultimately leading to cost savings for the business.

In addition to their efficiency, 300 micron strainers are also highly durable and long-lasting. This is important in industrial settings, where equipment is often subjected to harsh conditions and heavy use. By investing in a high-quality 300 micron strainer, businesses can ensure that they have a reliable filtration solution that will stand the test of time.

Furthermore, 300 micron strainers are versatile and can be used in a wide range of applications. Whether it’s filtering water, chemicals, or other liquids, these strainers are capable of handling a variety of substances with ease. This makes them a valuable asset for businesses in a range of industries, from manufacturing to pharmaceuticals.

Overall, the benefits of using 300 micron strainers in industrial settings are clear. From their ability to effectively remove large particles from liquids to their efficiency, durability, and versatility, these strainers offer a range of advantages for businesses looking to improve their filtration processes.

In conclusion, 300 micron strainers are an essential piece of equipment for industrial settings. Their ability to effectively remove large particles from liquids, coupled with their efficiency, durability, and versatility, make them a valuable asset for businesses in a range of industries. By investing in a high-quality 300 micron strainer, businesses can ensure that they have a reliable filtration solution that will help them maintain high levels of efficiency and quality in their operations.

How to Choose the Right 300 Micron Strainer for Domestic Applications

When it comes to choosing the right 300 micron strainer for domestic applications, there are a few key factors to consider. These strainers are essential for filtering out particles and debris from liquids, ensuring that your water, oil, or other fluids are clean and free of contaminants. With so many options on the market, it can be overwhelming to know which strainer is the best choice for your needs. In this article, we will discuss the importance of using a 300 micron strainer, as well as provide some tips on how to choose the right one for your specific application.

First and foremost, it is important to understand the significance of using a 300 micron strainer. A micron is a unit of measurement that is used to describe the size of particles that a strainer can filter out. In this case, a 300 micron strainer is capable of filtering out particles that are 300 microns in size or larger. This is important because particles of this size can be harmful if ingested or allowed to contaminate a fluid. By using a 300 micron strainer, you can ensure that your liquids are clean and safe for consumption or use.

When choosing a 300 micron strainer for domestic applications, there are a few key factors to consider. The first factor to consider is the material of the strainer. Strainers are typically made from stainless steel, brass, or plastic. Stainless steel is a durable and long-lasting option that is resistant to corrosion and rust. Brass is also a good choice for its durability and resistance to corrosion. Plastic strainers are lightweight and affordable, but may not be as durable as metal options.

Another important factor to consider when choosing a 300 micron strainer is the size of the strainer. The size of the strainer will depend on the volume of liquid that needs to be filtered, as well as the space available for installation. It is important to choose a strainer that is large enough to handle the flow rate of the liquid, but not so large that it takes up unnecessary space. Additionally, it is important to consider the shape of the strainer, as some shapes may be more suitable for certain applications than others.

In addition to material and size, it is also important to consider the type of connection that the strainer has. Some strainers have threaded connections that can be screwed onto a pipe or fitting, while others have slip connections that can be glued or soldered in place. The type of connection that is best for your application will depend on the specific requirements of your system.

Overall, choosing the right 300 micron strainer for domestic applications is essential for ensuring that your liquids are clean and free of contaminants. By considering factors such as material, size, and connection type, you can select a strainer that meets your specific needs. With the right strainer in place, you can rest assured that your fluids are filtered to the highest standard, keeping you and your family safe and healthy.

Maintenance Tips for Ensuring Efficient Performance of 300 Micron Strainers

When it comes to maintaining the efficiency of 300 micron strainers for industrial and domestic use, there are several key tips to keep in mind. These strainers play a crucial role in filtering out debris and particles from liquids, ensuring that equipment and systems operate smoothly and efficiently. By following these maintenance tips, you can help prolong the life of your strainers and ensure they continue to perform at their best.

One of the most important maintenance tips for 300 micron strainers is to regularly clean and inspect them. Over time, debris and particles can build up in the strainer, reducing its effectiveness and potentially causing damage to equipment downstream. By cleaning the strainer on a regular basis, you can prevent these issues and ensure that it continues to filter out particles effectively.

When cleaning the strainer, it is important to use the proper tools and techniques. Start by removing the strainer from the system and rinsing it with water to remove any loose debris. Then, use a brush or soft cloth to gently scrub away any remaining particles. Be sure to pay special attention to the mesh screen, as this is where most of the debris will accumulate. Once the strainer is clean, inspect it for any signs of damage or wear, such as tears in the mesh or corrosion on the frame. If any issues are found, it is important to address them promptly to prevent further damage.

In addition to regular cleaning, it is also important to replace the mesh screen in the strainer as needed. Over time, the mesh can become clogged or damaged, reducing the strainer’s effectiveness. By replacing the mesh screen on a regular basis, you can ensure that the strainer continues to filter out particles efficiently. Be sure to use a mesh screen that is compatible with your specific strainer model to ensure proper fit and performance.

Another important maintenance tip for 300 micron strainers is to monitor the pressure differential across the strainer. As debris builds up in the strainer, it can cause the pressure drop across the strainer to increase. By monitoring the pressure drop on a regular basis, you can identify when the strainer needs to be cleaned or replaced. This can help prevent damage to equipment downstream and ensure that the strainer continues to perform at its best.

Finally, it is important to follow the manufacturer’s recommendations for maintenance and care of your 300 micron strainer. Each strainer model may have specific requirements for cleaning, inspection, and replacement, so be sure to consult the manufacturer’s guidelines for best practices. By following these recommendations, you can help prolong the life of your strainer and ensure that it continues to operate efficiently.

In conclusion, maintaining the efficiency of 300 micron strainers is essential for ensuring the smooth operation of industrial and domestic systems. By following these maintenance tips, you can help prolong the life of your strainer and ensure that it continues to filter out particles effectively. Remember to clean and inspect the strainer regularly, replace the mesh screen as needed, monitor the pressure drop across the strainer, and follow the manufacturer’s recommendations for maintenance. By taking these steps, you can help ensure that your 300 micron strainer continues to perform at its best for years to come.