Table of Contents

Benefits of Using 25 Micron Screens for Improved Filtration Efficiency

In the world of filtration processes, efficiency is key. Whether you are working in the food and beverage industry, pharmaceuticals, or any other field that requires precise filtration, having the right equipment is essential. One crucial component of any filtration system is the screen used to separate particles from liquids or gases. 25 micron screens are a popular choice for many industries due to their ability to provide high-quality filtration results.

One of the primary benefits of using 25 micron screens is their efficiency in capturing small particles. With a mesh size of 25 microns, these screens are able to trap particles as small as 25 microns in size, ensuring that only the cleanest liquids or gases pass through. This level of precision is crucial in industries where even the smallest impurities can have a significant impact on the final product.

Another advantage of 25 micron screens is their durability. Made from high-quality materials such as stainless steel or nylon, these screens are designed to withstand the rigors of continuous use. This means that you can rely on your 25 micron screen to provide consistent filtration results over an extended period of time, saving you time and money on frequent replacements.

In addition to their efficiency and durability, 25 micron screens are also easy to clean and maintain. With regular cleaning and proper care, these screens can last for years without losing their effectiveness. This not only reduces downtime for maintenance but also ensures that your filtration system operates at peak performance at all times.

Furthermore, using 25 micron screens can help improve the overall quality of your products. By removing even the smallest particles from your liquids or gases, these screens can help you achieve a higher level of purity in your final product. This is especially important in industries such as pharmaceuticals or electronics, where product quality is paramount.

Overall, the benefits of using 25 micron screens for filtration processes are clear. From their efficiency in capturing small particles to their durability and ease of maintenance, these screens offer a range of advantages that can help improve the quality and efficiency of your filtration system. Whether you are looking to upgrade your current system or are in the process of designing a new one, investing in 25 micron screens is a smart choice that can yield significant benefits in the long run.

In conclusion, 25 micron screens are an essential component of any high-quality filtration system. Their efficiency, durability, and ease of maintenance make them a popular choice for industries that require precise filtration results. By investing in 25 micron screens, you can ensure that your filtration processes operate at peak performance, resulting in cleaner, purer products and improved overall efficiency.

How to Choose the Right 25 Micron Screen for Your Filtration Needs

When it comes to filtration processes, having the right equipment is crucial to achieving high-quality results. One key component of many filtration systems is the 25 micron screen. These screens are designed to capture particles that are 25 microns or larger in size, making them ideal for a wide range of applications. However, not all 25 micron screens are created equal, and choosing the right one for your specific needs is essential for achieving efficient and effective filtration.

One of the first things to consider when selecting a 25 micron screen is the material it is made from. Screens can be constructed from a variety of materials, including stainless steel, nylon, and polyester. Each material has its own unique properties that can impact the performance and longevity of the screen. Stainless steel screens, for example, are known for their durability and resistance to corrosion, making them a popular choice for industrial applications. Nylon screens, on the other hand, are lightweight and flexible, making them ideal for applications where ease of handling is important.

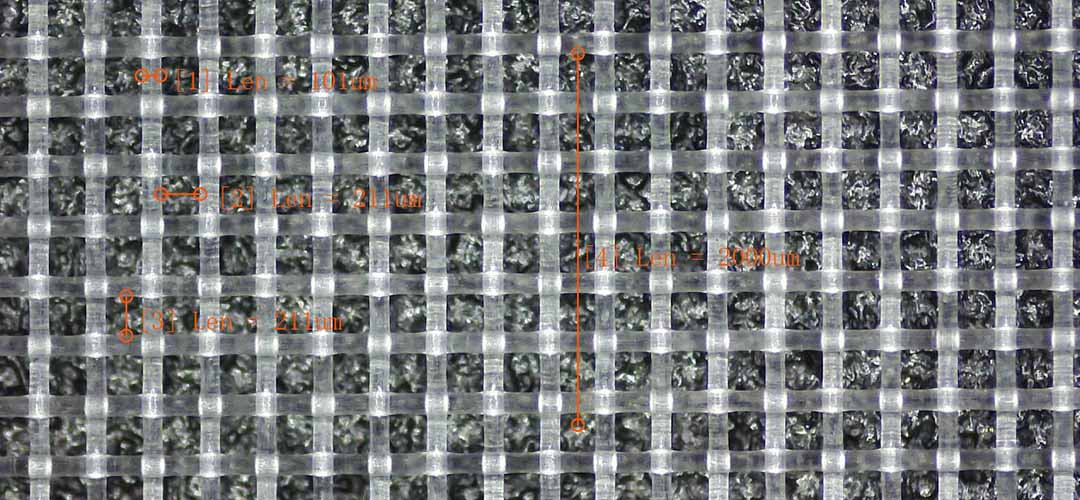

In addition to material, the design of the screen is also an important factor to consider. Some screens are woven, while others are perforated or etched. Woven screens are typically more durable and have a higher flow rate, making them ideal for applications where high pressure or high temperatures are present. Perforated screens, on the other hand, are better suited for applications where a finer filtration is required, as they can capture smaller particles than woven screens.

Another important consideration when choosing a 25 micron screen is the size and shape of the screen openings. Screens with larger openings will allow for a higher flow rate, but may not capture as many particles as screens with smaller openings. The shape of the openings can also impact the efficiency of the screen, with square or rectangular openings typically providing better filtration than round or oval openings.

When selecting a 25 micron screen, it is also important to consider the compatibility of the screen with your filtration system. Screens come in a variety of sizes and configurations, so it is important to choose one that will fit properly and work effectively with your existing equipment. Additionally, some screens are designed for specific applications, such as water filtration or oil filtration, so be sure to choose a screen that is appropriate for your specific needs.

In conclusion, choosing the right 25 micron screen for your filtration needs is essential for achieving efficient and effective results. Consider factors such as material, design, size and shape of openings, and compatibility with your filtration system when making your selection. By taking the time to choose the right screen, you can ensure that your filtration process runs smoothly and produces high-quality results.

Maintenance Tips for Ensuring Longevity and Effectiveness of 25 Micron Screens

When it comes to high-quality filtration processes, 25 micron screens are essential components that play a crucial role in ensuring the efficiency and effectiveness of the filtration system. These screens are designed to capture particles as small as 25 microns, making them ideal for applications that require fine filtration. However, in order to maintain the longevity and effectiveness of 25 micron screens, proper maintenance is key.

One of the most important maintenance tips for 25 micron screens is regular cleaning. Over time, particles and debris can accumulate on the surface of the screen, reducing its ability to effectively filter out contaminants. To prevent this buildup, it is important to clean the screen on a regular basis. This can be done by removing the screen from the filtration system and gently washing it with a mild detergent and water. It is important to avoid using harsh chemicals or abrasive materials, as these can damage the screen and reduce its effectiveness.

In addition to regular cleaning, it is also important to inspect the screen for any signs of damage or wear. If the screen is torn or damaged in any way, it should be replaced immediately to prevent contaminants from bypassing the filtration system. Regular inspections can help identify any issues early on and prevent costly repairs or replacements down the line.

Another important maintenance tip for 25 micron screens is to ensure proper installation and alignment. Improper installation can lead to leaks or bypassing of contaminants, reducing the effectiveness of the filtration system. It is important to follow the manufacturer’s guidelines for installation and alignment to ensure that the screen is properly positioned and sealed within the filtration system.

In addition to regular cleaning and inspections, it is also important to monitor the pressure differential across the screen. A sudden increase in pressure differential can indicate a clogged or damaged screen, which can lead to reduced filtration efficiency. By monitoring the pressure regularly, you can identify any issues early on and take corrective action to prevent further damage to the screen.

Overall, proper maintenance is essential for ensuring the longevity and effectiveness of 25 micron screens in high-quality filtration processes. By following these maintenance tips, you can help extend the life of your screens and ensure that your filtration system continues to operate at peak performance. Remember to clean the screen regularly, inspect it for damage, ensure proper installation and alignment, and monitor the pressure across the screen. By taking these steps, you can help maximize the efficiency and effectiveness of your filtration system for years to come.