Table of Contents

Benefits of Using 20 micron filter cloth in Industrial Filtration Processes

Efficient 20 Micron Filter Cloth for Industrial Filtration Solutions

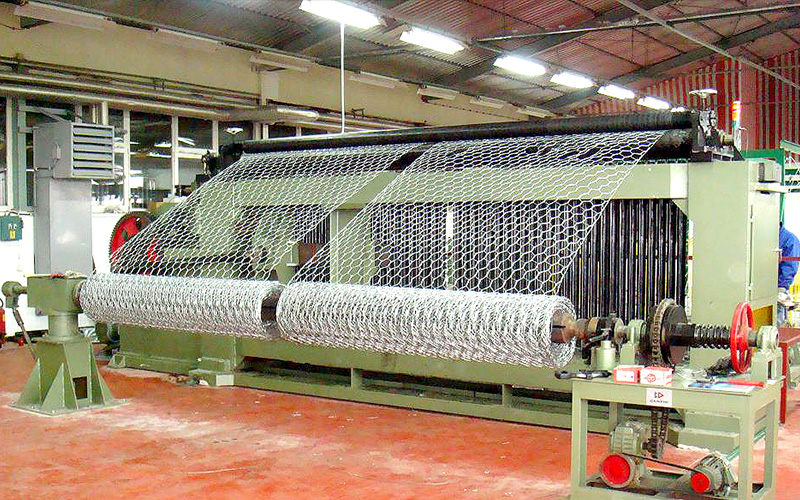

In the world of industrial filtration, finding the right filter cloth is crucial for achieving optimal results. One such cloth that has gained popularity in recent years is the 20 micron filter cloth. With its ability to efficiently capture particles as small as 20 microns, this cloth offers numerous benefits for industrial filtration processes.

First and foremost, the 20 micron filter cloth is highly efficient in capturing particles of various sizes. This is particularly important in industries where the filtration of fine particles is essential. Whether it is removing contaminants from water or separating solids from liquids, this cloth can effectively trap particles as small as 20 microns, ensuring a clean and purified end product.

Moreover, the 20 micron filter cloth is known for its durability and longevity. Made from high-quality materials, this cloth can withstand the harsh conditions often encountered in industrial filtration processes. It is resistant to chemicals, abrasion, and high temperatures, making it an ideal choice for demanding applications. By using this cloth, businesses can reduce downtime and maintenance costs associated with frequent cloth replacements.

Another advantage of using the 20 micron filter cloth is its high flow rate. Unlike some other filter cloths, this cloth allows for a smooth and uninterrupted flow of liquid or gas through the filtration system. This not only improves the overall efficiency of the process but also reduces the energy consumption required for filtration. By maximizing the flow rate, businesses can increase productivity and save on operational costs.

Furthermore, the 20 micron filter cloth offers excellent cake release properties. When particles are captured on the surface of the cloth, they form a layer known as the filter cake. With its unique design, this cloth allows for easy release of the filter cake during the cleaning process. This not only simplifies maintenance but also ensures consistent filtration performance over time.

Additionally, the 20 micron filter cloth is easy to install and replace. Its standardized dimensions and compatibility with various filtration systems make it a convenient choice for businesses. Whether it is a new installation or a replacement, this cloth can be quickly and effortlessly integrated into existing filtration setups. This saves time and resources, allowing businesses to focus on their core operations.

Lastly, the 20 micron filter cloth is cost-effective. Its efficiency, durability, and ease of use contribute to long-term cost savings for businesses. By reducing the need for frequent cloth replacements, minimizing downtime, and optimizing energy consumption, this cloth offers a high return on investment. Moreover, its competitive pricing makes it an affordable choice for businesses of all sizes.

In conclusion, the 20 micron filter cloth is a highly efficient solution for industrial filtration processes. Its ability to capture particles as small as 20 microns, durability, high flow rate, excellent cake release properties, ease of installation and replacement, and cost-effectiveness make it an ideal choice for businesses. By investing in this cloth, businesses can achieve superior filtration results, improve productivity, and save on operational costs.

How to Choose the Right 20 Micron Filter Cloth for Your Specific Filtration Needs

When it comes to industrial filtration solutions, choosing the right filter cloth is crucial for achieving optimal performance. One common choice for many applications is a 20 micron filter cloth, which offers a fine level of filtration that is suitable for a wide range of industries. However, not all 20 micron filter cloths are created equal, and it is important to select the right one for your specific filtration needs.

One of the key factors to consider when choosing a 20 micron filter cloth is the material it is made from. Different materials offer varying levels of durability, chemical resistance, and filtration efficiency. For example, polypropylene filter cloths are known for their excellent chemical resistance and are often used in applications where harsh chemicals are present. On the other hand, polyester filter cloths are known for their high tensile strength and are often used in applications where mechanical stress is a concern.

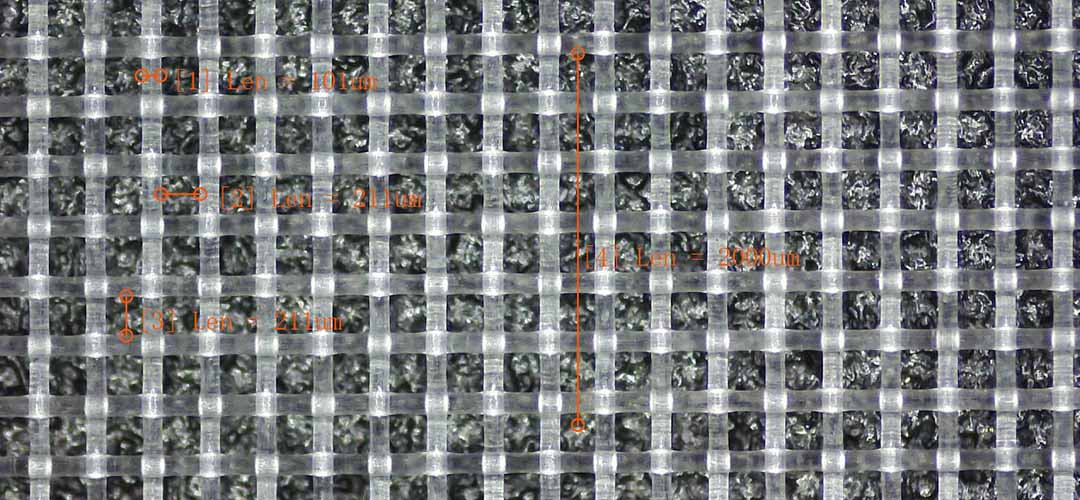

In addition to the material, the weave pattern of the filter cloth is also an important consideration. The weave pattern determines the porosity of the cloth, which in turn affects the filtration efficiency. Common weave patterns for 20 micron filter cloths include plain weave, twill weave, and satin weave. Each weave pattern offers different levels of filtration efficiency and flow rate, so it is important to choose the one that best suits your specific needs.

Another important factor to consider when choosing a 20 micron filter cloth is the finish of the cloth. The finish can affect the performance of the cloth in terms of cake release, resistance to blinding, and overall filtration efficiency. Common finishes for filter cloths include calendered, singed, and glazed. Each finish offers different benefits, so it is important to choose the one that will best meet your filtration requirements.

When selecting a 20 micron filter cloth, it is also important to consider the operating conditions of your filtration system. Factors such as temperature, pressure, and chemical exposure can all affect the performance of the filter cloth. It is important to choose a filter cloth that is designed to withstand the specific operating conditions of your system to ensure optimal performance and longevity.

In conclusion, choosing the right 20 micron filter cloth for your specific filtration needs is essential for achieving efficient and effective filtration. By considering factors such as material, weave pattern, finish, and operating conditions, you can select a filter cloth that will provide the level of filtration efficiency and durability required for your application. With the right filter cloth in place, you can ensure that your industrial filtration system operates at peak performance and delivers reliable results.

Case Studies: Successful Implementation of 20 Micron Filter Cloth in Industrial Filtration Solutions

In the world of industrial filtration, finding the right filter cloth is crucial to ensuring the efficiency and effectiveness of the filtration process. One common type of filter cloth used in industrial applications is the 20 micron filter cloth. This type of filter cloth is known for its ability to capture particles as small as 20 microns in size, making it ideal for a wide range of industrial filtration solutions.

One successful case study of the implementation of 20 micron filter cloth in industrial filtration solutions comes from a manufacturing plant that produces automotive parts. The plant was experiencing issues with their current filtration system, as it was not effectively capturing small particles that were contaminating their final products. After consulting with filtration experts, they decided to switch to a 20 micron filter cloth to improve the efficiency of their filtration process.

The results were immediate and impressive. The 20 micron filter cloth was able to capture particles as small as 20 microns, significantly reducing the amount of contamination in the final products. This led to a decrease in product defects and an increase in overall product quality. The plant was able to save time and money by reducing the need for rework and improving the efficiency of their production process.

Another successful case study of the implementation of 20 micron filter cloth comes from a chemical processing plant. The plant was struggling with high levels of contamination in their process water, which was affecting the quality of their products. After switching to a 20 micron filter cloth, they were able to effectively remove the contaminants from their process water, resulting in cleaner and higher quality products.

The 20 micron filter cloth also proved to be cost-effective for the plant, as it required less frequent replacement compared to their previous filter cloth. This led to savings in both time and money, as the plant was able to reduce downtime and maintenance costs associated with their filtration system.

Overall, the successful implementation of 20 micron filter cloth in industrial filtration solutions has proven to be a game-changer for many companies across various industries. Its ability to capture small particles with precision and efficiency has led to improved product quality, reduced contamination, and cost savings for businesses.

In conclusion, the use of 20 micron filter cloth in industrial filtration solutions has been shown to be an effective and efficient way to improve the quality and efficiency of filtration processes. By capturing particles as small as 20 microns, this type of filter cloth is able to provide superior filtration results and help businesses achieve their production goals. Whether it’s in automotive manufacturing, chemical processing, or any other industry that requires precise filtration, the 20 micron filter cloth is a reliable solution that delivers results.