Table of Contents

Benefits of Using 200 Mesh Filters for Industrial Applications

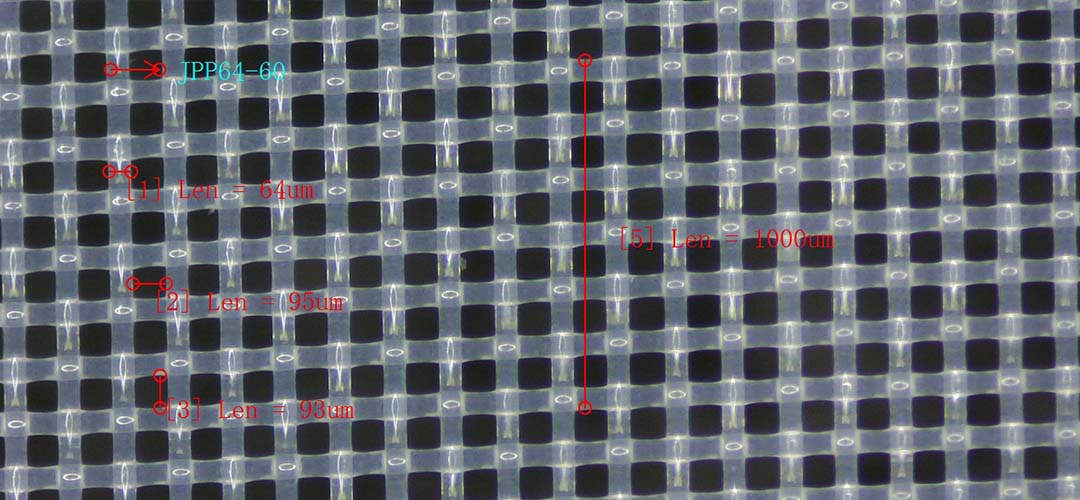

When it comes to industrial applications, having the right filtration system in place is crucial for ensuring the efficiency and longevity of equipment. One type of filter that has proven to be durable and reliable for a wide range of industrial applications is the 200 mesh filter. These filters are designed to remove particles as small as 74 microns, making them ideal for industries that require high levels of filtration.

One of the key benefits of using 200 mesh filters in industrial applications is their ability to effectively remove contaminants from liquids and gases. This is essential for industries such as oil and gas, chemical processing, and food and beverage production, where even the smallest particles can cause damage to equipment or compromise product quality. By using a 200 mesh filter, companies can ensure that their processes run smoothly and efficiently, without the risk of contamination.

Another advantage of 200 mesh filters is their durability and reliability. These filters are typically made from high-quality materials such as stainless steel or brass, which are able to withstand high temperatures and pressures without degrading. This makes them ideal for use in harsh industrial environments where other types of filters may fail. Additionally, 200 mesh filters are easy to clean and maintain, reducing downtime and ensuring that equipment remains operational for longer periods of time.

In addition to their durability and reliability, 200 mesh filters are also highly versatile and can be used in a wide range of industrial applications. Whether filtering water, oil, chemicals, or gases, these filters are able to effectively remove contaminants and ensure the purity of the final product. This versatility makes them a cost-effective solution for companies looking to streamline their filtration processes and improve overall efficiency.

Furthermore, 200 mesh filters are available in a variety of sizes and configurations to suit different industrial applications. Whether a company needs a small filter for a laboratory setting or a large filter for a production facility, there are options available to meet their specific needs. This flexibility allows companies to customize their filtration systems to achieve the best results for their particular industry.

Overall, the benefits of using 200 mesh filters for industrial applications are clear. From their ability to effectively remove contaminants to their durability and versatility, these filters are an essential component of any industrial filtration system. By investing in high-quality 200 mesh filters, companies can ensure the efficiency and reliability of their equipment, leading to improved productivity and cost savings in the long run.

How to Choose the Right 200 Mesh Filter for Residential Use

When it comes to choosing the right 200 mesh filter for residential use, there are several factors to consider to ensure that you are getting a durable and reliable product that meets your specific needs. 200 mesh filters are commonly used in a variety of applications, including water filtration, oil filtration, and air filtration. These filters are designed to remove particles as small as 74 microns, making them ideal for capturing fine particles and ensuring clean and safe air or water.

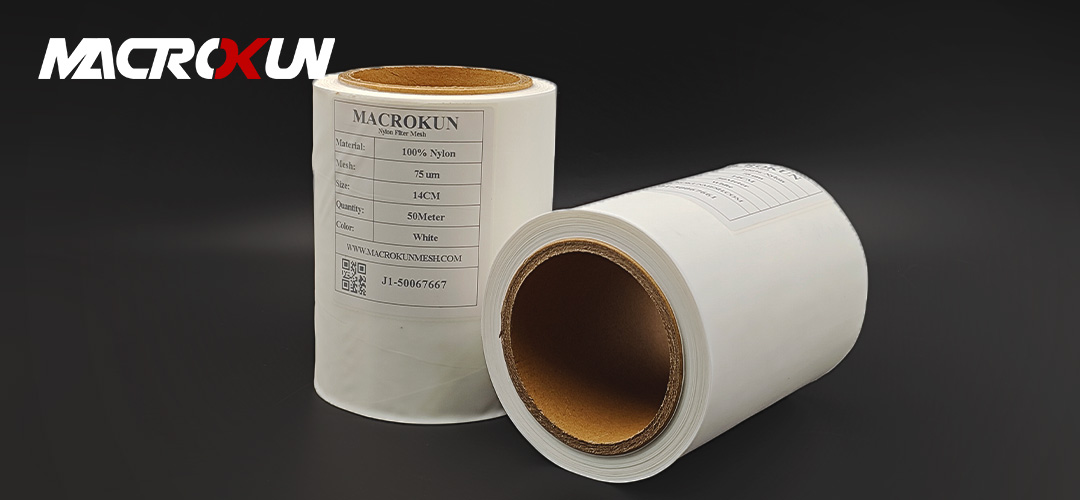

One of the first things to consider when choosing a 200 mesh filter for residential use is the material of the filter. Stainless steel is a popular choice for mesh filters due to its durability and resistance to corrosion. Stainless steel mesh filters are also easy to clean and maintain, making them a practical choice for residential use. Additionally, stainless steel mesh filters are capable of withstanding high temperatures, making them suitable for a wide range of applications.

Another important factor to consider when choosing a 200 mesh filter for residential use is the size of the filter. The size of the filter will depend on the specific application and the amount of filtration required. It is important to choose a filter that is the right size for your needs to ensure optimal performance and efficiency. Additionally, consider the flow rate of the filter to ensure that it can handle the volume of air or water that needs to be filtered.

In addition to material and size, it is also important to consider the design of the 200 mesh filter. Look for filters that are well-constructed and have a sturdy frame to ensure durability and reliability. Filters with reinforced edges and a strong mesh material are less likely to break or tear, ensuring long-lasting performance. Additionally, consider the design of the filter housing to ensure that it is easy to install and maintain.

When choosing a 200 mesh filter for residential use, it is also important to consider the brand and reputation of the manufacturer. Look for reputable brands that have a history of producing high-quality filters that are built to last. Reading customer reviews and testimonials can also help you gauge the reliability and performance of a particular filter.

Finally, consider the cost of the 200 mesh filter. While it is important to invest in a high-quality filter that will last, it is also important to consider your budget. Compare prices from different manufacturers and suppliers to find a filter that offers the best value for your money.

In conclusion, choosing the right 200 mesh filter for residential use requires careful consideration of material, size, design, brand, and cost. By taking the time to research and compare different filters, you can ensure that you are getting a durable and reliable product that meets your specific needs. Investing in a high-quality 200 mesh filter will help you maintain clean and safe air or water in your home for years to come.

Maintenance Tips for Ensuring Longevity of Durable 200 Mesh Filters

When it comes to ensuring the longevity and efficiency of your industrial or residential filtration system, using durable and reliable 200 mesh filters is essential. These filters are designed to trap particles as small as 74 microns, making them ideal for a wide range of applications, from water treatment to oil and gas filtration. However, like any filtration system, proper maintenance is key to ensuring that your 200 mesh filters continue to perform at their best.

One of the most important maintenance tips for ensuring the longevity of your 200 mesh filters is to regularly inspect and clean them. Over time, particles and debris can build up on the surface of the filter, reducing its effectiveness and potentially causing damage. By inspecting your filters on a regular basis and cleaning them as needed, you can prevent clogs and ensure that your filtration system continues to operate efficiently.

When cleaning your 200 mesh filters, it’s important to use the proper techniques and tools to avoid damaging the filter material. For most filters, a gentle rinse with water or a mild detergent is sufficient to remove debris and restore the filter’s effectiveness. However, if your filters are heavily clogged or coated with stubborn residue, you may need to use a more aggressive cleaning method, such as soaking the filters in a cleaning solution or using a pressure washer.

In addition to regular cleaning, it’s also important to replace your 200 mesh filters on a regular basis. Over time, the filter material can become worn or damaged, reducing its ability to trap particles effectively. By replacing your filters according to the manufacturer’s recommendations, you can ensure that your filtration system continues to operate at peak performance and avoid costly repairs or downtime.

Another important maintenance tip for ensuring the longevity of your 200 mesh filters is to monitor the pressure differential across the filter. As particles are trapped in the filter material, the pressure on the upstream side of the filter will increase, while the pressure on the downstream side will decrease. By monitoring the pressure drop across the filter, you can determine when it’s time to clean or replace the filter, preventing damage to your filtration system and ensuring that it continues to operate efficiently.

Finally, it’s important to protect your 200 mesh filters from harsh chemicals, extreme temperatures, and other environmental factors that can cause damage. By storing your filters in a clean, dry environment and avoiding exposure to corrosive substances, you can extend the life of your filters and ensure that they continue to perform at their best.

In conclusion, proper maintenance is essential for ensuring the longevity and efficiency of your durable and reliable 200 mesh filters. By regularly inspecting and cleaning your filters, replacing them as needed, monitoring the pressure drop across the filter, and protecting them from damage, you can extend the life of your filters and ensure that your filtration system continues to operate at peak performance. With these maintenance tips in mind, you can enjoy the benefits of clean, filtered water or oil for years to come.