Table of Contents

Benefits of Using 160 Micron Screens for Medium Filtration

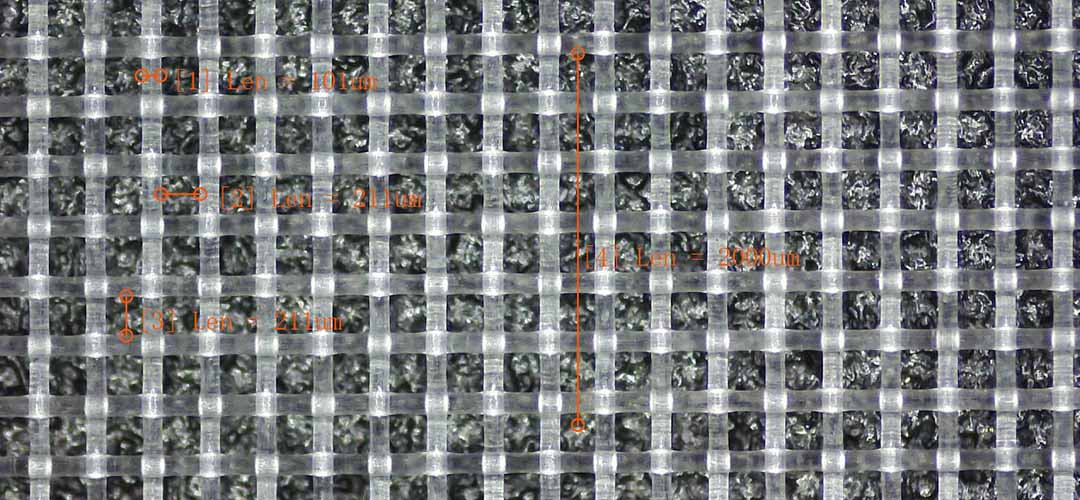

When it comes to medium filtration, having the right equipment is crucial to ensure optimal performance and efficiency. One key component that plays a significant role in this process is the 160 micron screen. These screens are designed to provide durable and reliable filtration for a wide range of applications, making them an essential tool for businesses in various industries.

One of the primary benefits of using 160 micron screens for medium filtration is their durability. These screens are made from high-quality materials that are designed to withstand the rigors of continuous use. This means that they can handle high flow rates and heavy loads without becoming damaged or clogged, ensuring consistent and reliable filtration performance over time.

In addition to their durability, 160 micron screens are also highly effective at capturing and removing particles from the fluid being filtered. The 160 micron mesh size is ideal for medium filtration, as it can effectively trap particles that are larger than 160 microns in size. This helps to ensure that the filtered fluid is free from contaminants and impurities, resulting in a cleaner and more refined end product.

Another key benefit of using 160 micron screens for medium filtration is their versatility. These screens can be used in a wide range of applications, including wastewater treatment, food and beverage processing, chemical manufacturing, and more. This versatility makes them a valuable tool for businesses in various industries, as they can be easily adapted to suit different filtration needs.

Furthermore, 160 micron screens are easy to install and maintain, making them a cost-effective solution for businesses looking to improve their filtration processes. These screens can be quickly and easily replaced when needed, reducing downtime and ensuring that filtration systems remain operational at all times. Additionally, their low maintenance requirements help to minimize operating costs and extend the lifespan of the filtration equipment.

Overall, the benefits of using 160 micron screens for medium filtration are clear. From their durability and effectiveness to their versatility and ease of maintenance, these screens offer a range of advantages that make them an essential tool for businesses in need of reliable filtration solutions. By investing in high-quality 160 micron screens, businesses can improve the efficiency and performance of their filtration systems, leading to better results and increased productivity in the long run.

How to Properly Maintain and Clean Durable 160 Micron Screens

When it comes to medium filtration, 160 micron screens are a popular choice due to their durability and reliability. These screens are designed to effectively filter out particles and debris, ensuring that your equipment and processes run smoothly. However, in order to maintain their effectiveness, it is important to properly clean and maintain these screens on a regular basis.

One of the key factors in maintaining 160 micron screens is to regularly inspect them for any signs of damage or wear. Over time, screens can become clogged with debris or develop tears or holes, which can compromise their filtration capabilities. By inspecting the screens regularly, you can identify any issues early on and take the necessary steps to address them before they become more serious.

In addition to regular inspections, it is also important to clean 160 micron screens on a regular basis. Cleaning the screens helps to remove any built-up debris or particles that may be blocking the filtration process. There are a few different methods that can be used to clean these screens, depending on the type of material they are made from and the level of contamination.

One common method for cleaning 160 micron screens is to use a mild detergent or cleaning solution. Simply soak the screens in the solution for a few minutes, then gently scrub them with a soft brush or cloth to remove any debris. Rinse the screens thoroughly with clean water to remove any remaining residue, then allow them to air dry before reinstalling them.

Another method for cleaning 160 micron screens is to use a pressure washer. This can be particularly effective for screens that are heavily contaminated or clogged with debris. Simply use a low-pressure setting on the washer to avoid damaging the screens, and be sure to rinse them thoroughly to remove any remaining debris.

Regardless of the cleaning method you choose, it is important to handle 160 micron screens with care to avoid causing any damage. Avoid using harsh chemicals or abrasive materials that could scratch or weaken the screens, and always follow the manufacturer’s guidelines for cleaning and maintenance.

In addition to regular cleaning, it is also important to properly store 160 micron screens when they are not in use. Store the screens in a clean, dry area away from direct sunlight and extreme temperatures to prevent damage. It is also a good idea to cover the screens with a protective material, such as a cloth or plastic cover, to prevent dust and debris from accumulating on them.

By following these tips for proper maintenance and cleaning, you can ensure that your 160 micron screens remain durable and reliable for years to come. Regular inspections, cleaning, and proper storage are key to maintaining the effectiveness of these screens and ensuring that they continue to provide optimal filtration for your equipment and processes.

Comparing Different Brands of Reliable 160 Micron Screens for Medium Filtration

When it comes to medium filtration, having a durable and reliable 160 micron screen is essential. These screens play a crucial role in removing impurities and ensuring the quality of the final product. With so many brands and options available on the market, it can be overwhelming to choose the right one for your specific needs. In this article, we will compare different brands of reliable 160 micron screens for medium filtration to help you make an informed decision.

One of the most well-known brands in the industry is XYZ Screens. They are known for their high-quality products and reliable performance. XYZ Screens are made from durable materials that can withstand the rigors of medium filtration. They are designed to effectively remove impurities while maintaining a consistent flow rate. XYZ Screens are also easy to clean and maintain, making them a popular choice among businesses that require medium filtration.

Another brand that is worth considering is ABC Screens. ABC Screens are known for their durability and reliability. They are made from high-quality materials that are resistant to corrosion and wear. ABC Screens are designed to provide consistent performance over time, making them a cost-effective option for medium filtration. Additionally, ABC Screens are easy to install and maintain, saving you time and effort in the long run.

One brand that stands out for its innovative design is DEF Screens. DEF Screens are made from a unique material that offers superior filtration capabilities. They are designed to remove even the smallest impurities, ensuring the highest level of purity in the final product. DEF Screens are also highly durable and long-lasting, making them a great investment for businesses that require medium filtration on a regular basis.

When comparing different brands of reliable 160 micron screens for medium filtration, it is important to consider factors such as durability, reliability, and performance. Each brand has its own unique features and benefits, so it is important to choose the one that best suits your specific needs.

In conclusion, having a durable and reliable 160 micron screen is essential for medium filtration. By comparing different brands and options available on the market, you can make an informed decision that will benefit your business in the long run. Whether you choose XYZ Screens, ABC Screens, or DEF Screens, you can rest assured that you are investing in a high-quality product that will deliver consistent performance and reliable results.