Table of Contents

Benefits of Using Durable 20 micron nylon mesh for filtration

When it comes to filtration, using the right materials is crucial to ensure efficient and effective results. One material that has proven to be highly effective in filtration applications is 20 micron nylon mesh. This durable material offers a range of benefits that make it an ideal choice for a variety of filtration needs.

One of the key benefits of using 20 micron nylon mesh is its durability. This material is designed to withstand high pressures and temperatures, making it ideal for use in demanding filtration applications. Whether you are filtering water, chemicals, or other substances, 20 micron nylon mesh can handle the job with ease.

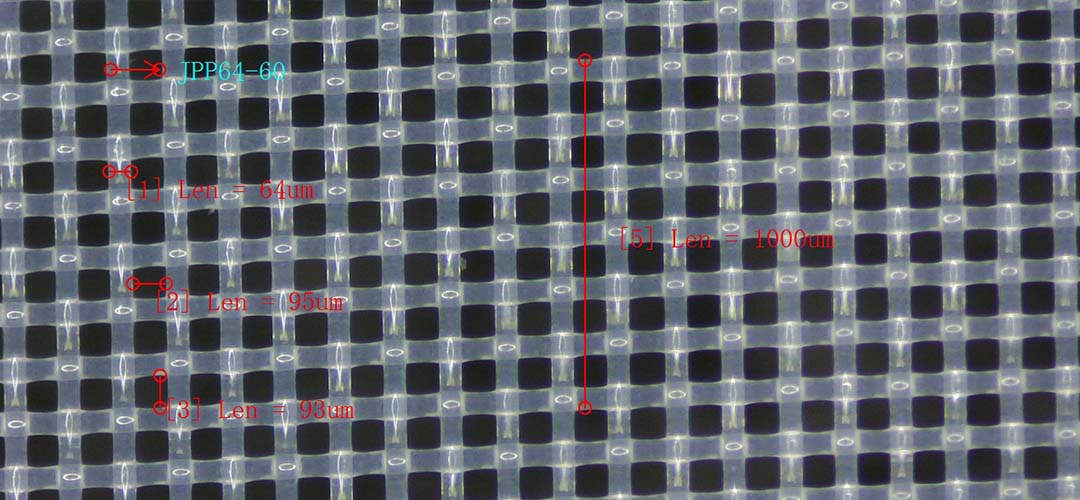

In addition to its durability, 20 micron nylon mesh is also highly efficient at capturing particles. The small pore size of this material allows it to effectively trap particles as small as 20 microns, ensuring that your filtration system is able to remove even the smallest impurities from the fluid being filtered. This level of filtration is essential in many industries where purity is of the utmost importance.

Another benefit of using 20 micron nylon mesh is its versatility. This material can be used in a wide range of filtration applications, from industrial processes to laboratory testing. Whether you are filtering liquids or gases, 20 micron nylon mesh can provide the level of filtration you need to achieve your desired results.

Furthermore, 20 micron nylon mesh is easy to clean and maintain, making it a cost-effective option for filtration systems. Unlike some other filtration materials that require frequent replacement, 20 micron nylon mesh can be cleaned and reused multiple times, saving you time and money in the long run.

In addition to its durability, efficiency, versatility, and cost-effectiveness, 20 micron nylon mesh is also resistant to chemicals and corrosion. This makes it an ideal choice for filtration applications where exposure to harsh chemicals or corrosive substances is a concern. With 20 micron nylon mesh, you can trust that your filtration system will continue to perform at its best, even in challenging environments.

Overall, the benefits of using 20 micron nylon mesh for filtration are clear. This durable material offers a high level of efficiency, versatility, and cost-effectiveness, making it an ideal choice for a wide range of filtration applications. Whether you are filtering water, chemicals, or other substances, 20 micron nylon mesh can provide the level of filtration you need to achieve your desired results. Trust in the durability and effectiveness of 20 micron nylon mesh for all your filtration needs.

How to Properly Maintain and Clean 20 Micron Nylon Mesh Filters

When it comes to filtration systems, 20 micron nylon mesh filters are a popular choice due to their durability and efficiency. These filters are commonly used in a variety of industries, including food and beverage, pharmaceuticals, and water treatment. However, in order to ensure that these filters continue to perform at their best, proper maintenance and cleaning are essential.

One of the key benefits of 20 micron nylon mesh filters is their ability to effectively capture particles as small as 20 microns in size. This level of filtration is crucial for industries that require high levels of cleanliness and purity in their processes. However, over time, these filters can become clogged with debris and contaminants, reducing their effectiveness. Regular maintenance and cleaning are necessary to prevent this from happening.

To properly maintain and clean 20 micron nylon mesh filters, it is important to follow a few simple steps. First, it is essential to regularly inspect the filters for any signs of damage or wear. If any tears or holes are found, the filter should be replaced immediately to prevent contaminants from passing through.

Next, the filters should be cleaned on a regular basis to remove any buildup of debris and contaminants. This can be done by soaking the filters in a solution of warm water and a mild detergent. The filters should then be gently scrubbed with a soft brush to remove any stubborn particles. After cleaning, the filters should be thoroughly rinsed with clean water to remove any remaining detergent residue.

In addition to regular cleaning, it is also important to properly store 20 micron nylon mesh filters when they are not in use. Filters should be stored in a clean, dry environment away from direct sunlight and extreme temperatures. This will help to prevent the filters from becoming damaged or degraded over time.

Another important aspect of maintaining 20 micron nylon mesh filters is to ensure that they are properly installed in the filtration system. Filters should be securely fastened in place to prevent any bypass of contaminants. It is also important to follow the manufacturer’s guidelines for the proper installation and use of the filters.

In conclusion, 20 micron nylon mesh filters are a durable and efficient option for filtration systems in a variety of industries. Proper maintenance and cleaning are essential to ensure that these filters continue to perform at their best. By following the steps outlined above, businesses can prolong the life of their filters and maintain high levels of cleanliness and purity in their processes.

Applications and Industries that Benefit from Efficient Filtration with 20 Micron Nylon Mesh

Efficient filtration is crucial in a wide range of industries, from food and beverage production to pharmaceutical manufacturing. One key component of effective filtration is the use of high-quality mesh materials. 20 micron nylon mesh is a popular choice for many applications due to its durability and efficiency.

Nylon mesh is known for its strength and resistance to abrasion, making it an ideal material for filtration purposes. The 20 micron size is particularly useful for capturing small particles and contaminants, ensuring that the final product is clean and free of impurities. This level of filtration is essential in industries where product quality is paramount.

One industry that benefits greatly from the use of 20 micron nylon mesh is the food and beverage industry. In food processing, it is crucial to remove any impurities or contaminants from the final product to ensure consumer safety. Nylon mesh provides an effective barrier against particles as small as 20 microns, making it an essential tool in maintaining high standards of quality and safety.

Similarly, the pharmaceutical industry relies on efficient filtration to ensure the purity of medications and medical devices. 20 micron nylon mesh is often used in the production of pharmaceutical products to remove any unwanted particles or debris. This level of filtration is essential in maintaining the efficacy and safety of pharmaceutical products, making nylon mesh a valuable asset in this industry.

Another industry that benefits from the use of 20 micron nylon mesh is the automotive industry. In automotive manufacturing, filtration is essential for ensuring the quality and performance of components such as fuel filters and air filters. Nylon mesh provides a reliable barrier against contaminants, helping to prolong the lifespan of these components and improve overall vehicle performance.

The aerospace industry also relies on efficient filtration to ensure the safety and reliability of aircraft components. 20 micron nylon mesh is often used in the production of aerospace components to remove any particles or debris that could compromise the integrity of the final product. This level of filtration is essential in maintaining the high standards of quality and safety required in the aerospace industry.

Overall, 20 micron nylon mesh is a versatile and durable material that is well-suited for a wide range of applications. Its strength and efficiency make it an ideal choice for industries that require high levels of filtration to ensure product quality and safety. Whether used in food processing, pharmaceutical manufacturing, automotive production, or aerospace engineering, nylon mesh provides a reliable solution for efficient filtration.

In conclusion, the use of 20 micron nylon mesh is essential for industries that require efficient filtration to maintain high standards of quality and safety. Its durability and efficiency make it a valuable asset in a wide range of applications, from food and beverage production to aerospace engineering. By investing in high-quality nylon mesh, industries can ensure that their products meet the highest standards of quality and reliability.