Table of Contents

Benefits of Using Durable 190 micron mesh Filters in Industrial Settings

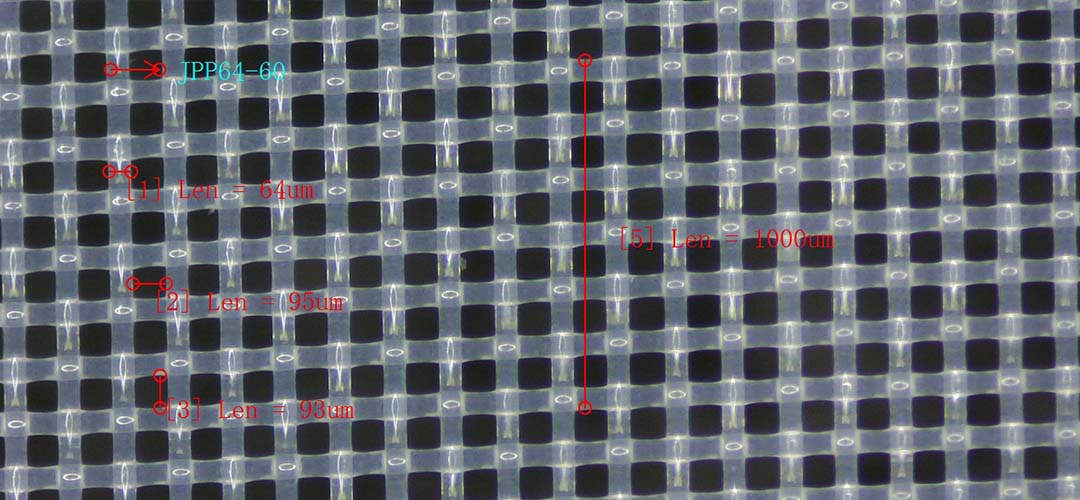

When it comes to industrial applications, having the right filtration system in place is crucial for ensuring the efficiency and longevity of equipment. One type of filter that has gained popularity in recent years is the durable 190 micron mesh filter. These filters are designed to withstand the harsh conditions of industrial settings and provide superior filtration performance.

One of the key benefits of using durable 190 micron mesh filters in industrial settings is their ability to effectively capture particles of various sizes. The 190 micron mesh size is ideal for capturing larger particles that may be present in industrial fluids or gases. This helps to prevent clogging of equipment and ensures that the system operates smoothly and efficiently.

In addition to their superior filtration capabilities, durable 190 micron mesh filters are also known for their durability and longevity. These filters are made from high-quality materials that are designed to withstand the rigors of industrial use. They are resistant to corrosion, abrasion, and high temperatures, making them ideal for use in a wide range of industrial applications.

Another benefit of using durable 190 micron mesh filters is their ease of maintenance. These filters are designed to be easily cleaned and maintained, reducing downtime and ensuring that the filtration system operates at peak efficiency. This can help to save time and money in the long run, as regular maintenance of the filters can help to extend their lifespan and prevent costly repairs or replacements.

Furthermore, durable 190 micron mesh filters are highly versatile and can be used in a variety of industrial applications. Whether you are filtering water, oil, chemicals, or gases, these filters are capable of providing reliable and efficient filtration performance. This versatility makes them a popular choice for a wide range of industries, including manufacturing, petrochemical, and food processing.

In conclusion, the benefits of using durable 190 micron mesh filters in industrial settings are clear. From their superior filtration capabilities to their durability and ease of maintenance, these filters offer a range of advantages that make them an ideal choice for a wide range of industrial applications. If you are looking for a reliable and efficient filtration solution for your industrial equipment, consider investing in durable 190 micron mesh filters. With their proven performance and durability, these filters are sure to meet your filtration needs and help you achieve optimal efficiency and productivity in your industrial operations.

How to Properly Maintain and Clean 190 Micron Mesh Filters for Longevity

When it comes to industrial applications, having the right filtration system in place is crucial for maintaining the efficiency and longevity of equipment. 190 micron mesh filters are a popular choice for many industries due to their durability and effectiveness in capturing particles of various sizes. However, in order to ensure that these filters continue to perform at their best, proper maintenance and cleaning are essential.

One of the key factors in maintaining 190 micron mesh filters is regular inspection. By routinely checking the filters for any signs of damage or clogging, you can prevent potential issues from arising and ensure that the filters are functioning properly. Inspecting the filters also allows you to identify any areas that may need special attention during the cleaning process.

When it comes to cleaning 190 micron mesh filters, it is important to use the right techniques and products to avoid damaging the filter material. One common method for cleaning these filters is to use a mild detergent and water solution. By gently scrubbing the filters with this solution, you can remove any built-up debris and restore the filter’s effectiveness.

In addition to using a detergent solution, it is also important to rinse the filters thoroughly after cleaning to remove any residue. This will help to prevent any leftover detergent from clogging the filter and affecting its performance. Once the filters have been cleaned and rinsed, it is important to allow them to dry completely before reinstalling them in the filtration system.

Another important aspect of maintaining 190 micron mesh filters is to replace them when necessary. Over time, filters can become worn out or damaged, which can affect their ability to effectively capture particles. By regularly replacing filters that are past their prime, you can ensure that your filtration system continues to operate at its best.

In addition to regular maintenance and cleaning, there are also some preventative measures that can be taken to extend the life of 190 micron mesh filters. One such measure is to install a pre-filter system to capture larger particles before they reach the 190 micron filters. This can help to reduce the amount of debris that the filters need to capture, ultimately prolonging their lifespan.

Overall, proper maintenance and cleaning are essential for ensuring the longevity and effectiveness of 190 micron mesh filters in industrial applications. By regularly inspecting, cleaning, and replacing filters when necessary, you can keep your filtration system running smoothly and avoid costly repairs or replacements. With the right care and attention, 190 micron mesh filters can continue to provide reliable filtration for years to come.

Case Studies Highlighting the Effectiveness of Durable 190 Micron Mesh Filters in Various Industrial Applications

Mesh filters are an essential component in many industrial applications, serving as a critical barrier to prevent contaminants from entering sensitive equipment or processes. When it comes to choosing the right mesh filter for your industrial needs, durability is a key factor to consider. One type of mesh filter that has proven to be highly effective in a wide range of industrial applications is the 190 micron mesh filter.

190 micron mesh filters are known for their durability and reliability, making them an ideal choice for industries that require a high level of filtration efficiency. These filters are made from high-quality materials that can withstand harsh operating conditions, ensuring long-lasting performance and minimal maintenance requirements.

One industry where 190 micron mesh filters have shown exceptional effectiveness is the oil and gas sector. In this industry, filtration is crucial to ensure the purity of the oil and gas being processed. 190 micron mesh filters are able to effectively remove contaminants such as sand, dirt, and other particles, ensuring that the final product meets the required quality standards.

Another industry where 190 micron mesh filters have proven to be highly effective is the food and beverage industry. In this industry, maintaining a clean and hygienic production environment is essential to ensure the safety and quality of the products being manufactured. 190 micron mesh filters are able to effectively remove impurities and contaminants from liquids and gases, helping to maintain the integrity of the final product.

In the pharmaceutical industry, where strict quality control measures are in place, 190 micron mesh filters have also shown their value. These filters are able to remove bacteria, viruses, and other harmful contaminants from pharmaceutical products, ensuring that they meet the required purity standards.

The automotive industry is another sector where 190 micron mesh filters have proven to be highly effective. In automotive manufacturing, the use of clean fluids and gases is essential to ensure the quality of the final product. 190 micron mesh filters are able to effectively remove contaminants from lubricants, coolants, and other fluids, helping to prolong the life of critical components and reduce maintenance costs.

In the mining industry, where the extraction and processing of minerals can generate a significant amount of dust and debris, 190 micron mesh filters have shown their ability to effectively capture and remove these contaminants. By using these filters, mining companies can improve air quality in their facilities and reduce the risk of equipment failure due to dust buildup.

Overall, 190 micron mesh filters have proven to be a reliable and durable solution for a wide range of industrial applications. Their ability to effectively remove contaminants and maintain a clean operating environment makes them an essential component in industries where filtration is critical. If you are looking for a high-quality mesh filter that can withstand the demands of your industrial application, consider investing in a 190 micron mesh filter for optimal performance and peace of mind.