Table of Contents

Benefits of Using Durable 10 Micron Stainless Steel Screens in Industrial Applications

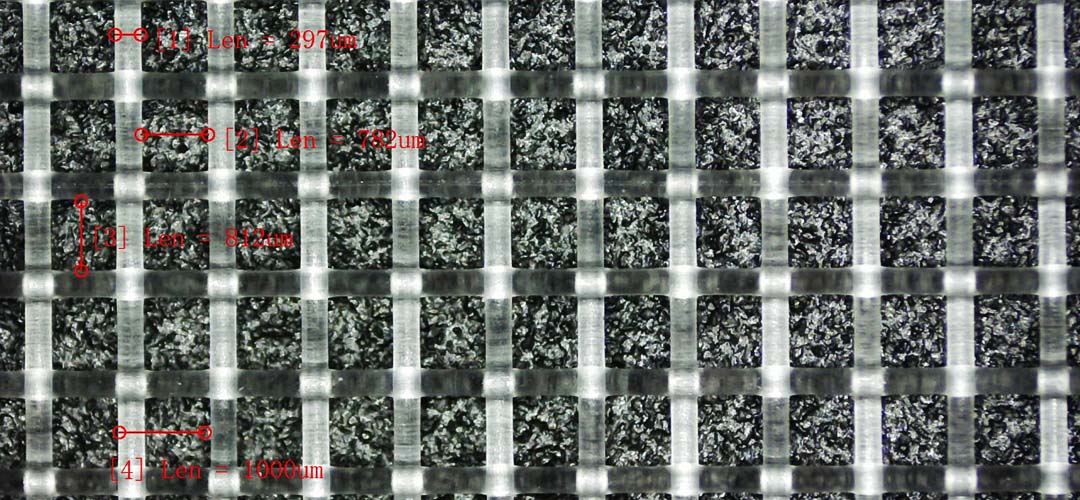

Stainless steel screens are a crucial component in many industrial applications, providing filtration and separation of materials in various processes. When it comes to choosing the right screen for your specific needs, durability is a key factor to consider. 10 micron stainless steel screens are known for their strength and longevity, making them an excellent choice for demanding industrial environments.

One of the primary benefits of using durable 10 micron stainless steel screens is their resistance to corrosion. Stainless steel is inherently resistant to rust and corrosion, making it ideal for use in applications where exposure to moisture or harsh chemicals is common. This resistance ensures that the screens will maintain their integrity and performance over time, even in challenging conditions.

In addition to their corrosion resistance, 10 micron stainless steel screens are also highly durable and able to withstand high temperatures and pressures. This durability makes them suitable for use in a wide range of industrial processes, from food and beverage production to pharmaceutical manufacturing. The screens can handle the rigors of these environments without warping or degrading, ensuring consistent performance and reliable filtration.

Another benefit of using durable 10 micron stainless steel screens is their versatility. These screens can be custom-designed to meet specific size and shape requirements, making them suitable for a wide range of applications. Whether you need a screen for particle separation, fluid filtration, or gas purification, stainless steel screens can be tailored to fit your needs precisely.

Furthermore, 10 micron stainless steel screens offer excellent filtration efficiency, thanks to their fine mesh size. The 10-micron openings in the screen allow for precise filtration of particles and contaminants, ensuring that only the desired materials pass through. This level of filtration is essential in many industrial processes, where the purity and quality of the final product are paramount.

In addition to their durability and efficiency, 10 micron stainless steel screens are also easy to clean and maintain. The smooth surface of stainless steel makes it resistant to buildup and fouling, allowing for easy cleaning and maintenance. This ease of maintenance helps to prolong the life of the screens and ensures consistent performance over time.

Overall, the benefits of using durable 10 micron stainless steel screens in industrial applications are clear. Their corrosion resistance, durability, versatility, filtration efficiency, and ease of maintenance make them an excellent choice for a wide range of industries. Whether you need a screen for liquid filtration, gas separation, or particle size reduction, stainless steel screens can provide the reliability and performance you need. Consider incorporating 10 micron stainless steel screens into your industrial processes to experience the benefits firsthand.

How to Properly Maintain and Clean 10 Micron Stainless Steel Screens for Longevity

Stainless steel screens are a crucial component in many industrial applications, providing filtration and separation of materials in various processes. These screens are known for their durability and longevity, making them a popular choice for industries such as food and beverage, pharmaceuticals, and chemical processing. One common type of stainless steel screen used in these applications is the 10-micron screen, which offers fine filtration capabilities for removing small particles from liquids or gases.

To ensure the longevity and effectiveness of 10-micron stainless steel screens, proper maintenance and cleaning are essential. Regular maintenance not only extends the lifespan of the screens but also ensures optimal performance in filtration processes. In this article, we will discuss how to properly maintain and clean 10-micron stainless steel screens to maximize their durability and efficiency.

One of the key aspects of maintaining 10-micron stainless steel screens is regular inspection. Inspecting the screens for any signs of wear, damage, or clogging is crucial to identify any issues early on and prevent them from escalating. Inspections should be conducted at regular intervals, depending on the frequency of use and the type of materials being filtered. Any damaged or worn-out screens should be replaced promptly to avoid compromising the filtration process.

In addition to regular inspections, proper cleaning of 10-micron stainless steel screens is essential for maintaining their effectiveness. Cleaning should be done using the appropriate methods and cleaning agents to ensure that the screens are free from contaminants and debris. One common method of cleaning stainless steel screens is using a combination of water and a mild detergent to remove any buildup or residue. It is important to avoid using harsh chemicals or abrasive materials that can damage the screens.

Ultrasonic cleaning is another effective method for cleaning 10-micron stainless steel screens. This method uses high-frequency sound waves to agitate the cleaning solution and remove contaminants from the screens. Ultrasonic cleaning is particularly useful for removing stubborn deposits or particles that are difficult to remove with traditional cleaning methods. However, it is important to follow the manufacturer’s guidelines and recommendations when using ultrasonic cleaning to avoid damaging the screens.

After cleaning, it is important to thoroughly rinse the screens with clean water to remove any remaining cleaning agents or residue. Proper rinsing ensures that the screens are free from contaminants and ready for use in filtration processes. Once the screens are clean and dry, they should be stored in a clean and dry environment to prevent contamination or damage.

In conclusion, proper maintenance and cleaning of 10-micron stainless steel screens are essential for maximizing their durability and efficiency in industrial applications. Regular inspections, proper cleaning methods, and storage practices are key to ensuring that the screens perform optimally and have a long lifespan. By following these guidelines, industries can maintain their stainless steel screens in top condition and achieve consistent and reliable filtration results.

Case Studies Highlighting Successful Implementation of Durable Stainless Steel Screens in Various Industrial Settings

Stainless steel screens have become a popular choice for industrial applications due to their durability and longevity. One particular type of stainless steel screen that has gained traction in the industry is the 10-micron stainless steel screen. These screens are known for their fine mesh size, making them ideal for filtering out even the smallest particles in various industrial processes.

One successful case study of the implementation of durable 10-micron stainless steel screens is in the pharmaceutical industry. Pharmaceutical companies rely on precise filtration processes to ensure the purity of their products. By using 10-micron stainless steel screens, these companies can effectively remove impurities and contaminants from their products, resulting in high-quality pharmaceuticals that meet strict regulatory standards.

Another industry that has benefited from the use of 10-micron stainless steel screens is the food and beverage industry. Food and beverage manufacturers require reliable filtration systems to maintain the quality and safety of their products. By incorporating 10-micron stainless steel screens into their production processes, these companies can effectively remove unwanted particles and debris, ensuring that their products meet the highest standards of quality and safety.

In the automotive industry, 10-micron stainless steel screens have proven to be invaluable in the manufacturing of precision components. Automotive manufacturers rely on filtration systems to ensure that their products meet strict tolerances and specifications. By using 10-micron stainless steel screens, these companies can effectively filter out contaminants and debris, resulting in high-quality components that meet the demanding requirements of the automotive industry.

The aerospace industry is another sector that has successfully implemented 10-micron stainless steel screens in its manufacturing processes. Aerospace manufacturers require filtration systems that can withstand extreme conditions and provide reliable performance. By using 10-micron stainless steel screens, these companies can ensure that their products meet the stringent requirements of the aerospace industry, resulting in components that are durable, reliable, and high-performing.

Overall, the successful implementation of durable 10-micron stainless steel screens in various industrial settings highlights the versatility and effectiveness of these screens in a wide range of applications. Whether in the pharmaceutical, food and beverage, automotive, or aerospace industries, 10-micron stainless steel screens have proven to be a reliable and cost-effective solution for filtration needs.

In conclusion, the use of 10-micron stainless steel screens in industrial applications has become increasingly popular due to their durability, longevity, and fine mesh size. These screens have been successfully implemented in various industries, including pharmaceuticals, food and beverage, automotive, and aerospace, where they have proven to be invaluable in ensuring the quality, safety, and performance of products. As industries continue to evolve and demand higher standards of quality and reliability, 10-micron stainless steel screens will undoubtedly remain a key component in filtration systems for years to come.