Table of Contents

Benefits of Using Coarse 1000 Micron Screens in Heavy-Duty Applications

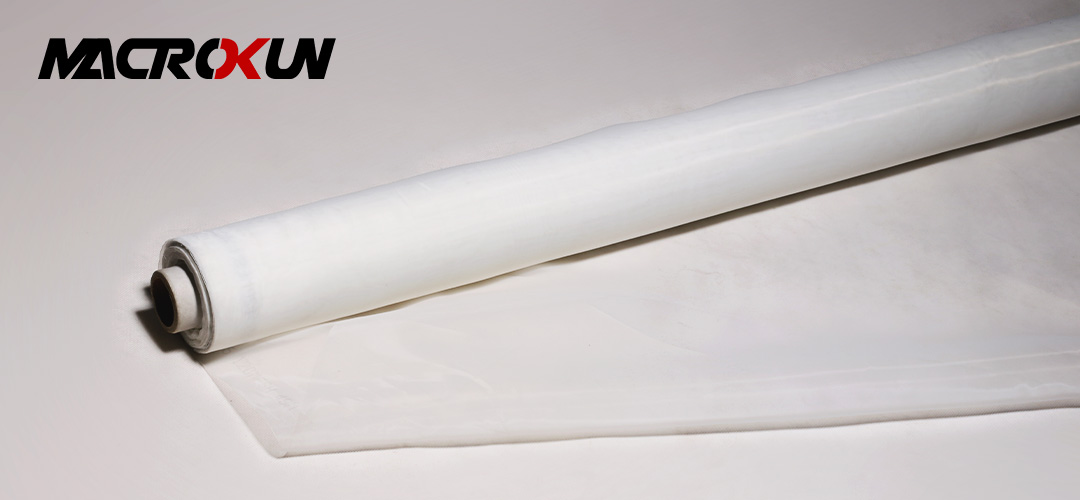

When it comes to heavy-duty applications, having the right equipment is crucial for ensuring efficiency and productivity. One key component that plays a significant role in many industrial processes is the use of coarse 1000 micron screens. These screens are designed to withstand the demands of heavy-duty applications and offer a range of benefits that make them an essential tool for industries such as mining, construction, and agriculture.

One of the primary benefits of using coarse 1000 micron screens in heavy-duty applications is their durability. These screens are made from high-quality materials that are able to withstand the wear and tear of continuous use in demanding environments. This durability ensures that the screens will last longer and require less frequent replacement, saving time and money in the long run.

In addition to their durability, coarse 1000 micron screens are also highly effective at separating materials of different sizes. These screens are designed with precision-cut holes that allow for the efficient separation of larger particles from smaller ones. This makes them ideal for applications where the size of the material being processed is critical, such as in mining operations or construction sites.

Another benefit of using coarse 1000 micron screens in heavy-duty applications is their versatility. These screens can be used in a wide range of industries and applications, making them a versatile tool for any business. Whether you are processing aggregates, separating minerals, or filtering liquids, coarse 1000 micron screens can help you achieve the desired results quickly and efficiently.

Furthermore, coarse 1000 micron screens are easy to install and maintain, making them a convenient option for businesses looking to streamline their operations. These screens can be easily integrated into existing equipment and require minimal maintenance to keep them running smoothly. This means less downtime and more productivity for your business.

In conclusion, coarse 1000 micron screens are an essential tool for heavy-duty applications in a variety of industries. Their durability, effectiveness, versatility, and ease of maintenance make them a valuable asset for any business looking to improve efficiency and productivity. By investing in coarse 1000 micron screens, you can ensure that your operations run smoothly and efficiently, leading to increased profitability and success.

How to Choose the Right Coarse 1000 micron screen for Your Specific Needs

When it comes to heavy-duty applications that require coarse screening, choosing the right 1000 micron screen is crucial. These screens are designed to handle large particles and high flow rates, making them ideal for industries such as mining, construction, and agriculture. However, with so many options available on the market, it can be challenging to determine which screen is best suited for your specific needs.

One of the first factors to consider when selecting a coarse 1000 micron screen is the material it is made from. Screens are typically constructed from materials such as stainless steel, polyurethane, or rubber. Stainless steel screens are durable and resistant to corrosion, making them ideal for applications where the screen will be exposed to harsh chemicals or abrasive materials. Polyurethane screens are known for their flexibility and abrasion resistance, making them a popular choice for applications where the screen may be subject to high impact or wear. Rubber screens are also flexible and resistant to abrasion, making them suitable for applications where noise reduction is a priority.

Another important consideration when choosing a coarse 1000 micron screen is the aperture size. The aperture size refers to the space between the wires or openings in the screen, and it determines the size of particles that can pass through. Screens with larger aperture sizes are better suited for applications where larger particles need to be separated, while screens with smaller aperture sizes are ideal for applications where finer particles need to be removed. It is essential to consider the size of the particles you are working with and select a screen with an appropriate aperture size to ensure optimal performance.

In addition to material and aperture size, it is also important to consider the type of weave used in the screen. Screens can be woven in a variety of patterns, including square, rectangular, and slotted. Each weave pattern offers different benefits in terms of strength, durability, and particle retention. Square weave screens are known for their strength and stability, making them suitable for heavy-duty applications. Rectangular weave screens are more flexible and offer better particle retention, making them ideal for applications where fine particles need to be separated. Slotted weave screens are designed to allow for high flow rates while still retaining particles, making them a versatile option for a wide range of applications.

When selecting a coarse 1000 micron screen, it is essential to consider the specific requirements of your application and choose a screen that is designed to meet those needs. By considering factors such as material, aperture size, and weave pattern, you can ensure that you select a screen that will provide optimal performance and durability in your specific application. Whether you are working in mining, construction, or agriculture, choosing the right coarse 1000 micron screen is essential for achieving efficient and effective screening results.

Maintenance Tips for Ensuring Longevity and Efficiency of Coarse 1000 Micron Screens in Heavy-Duty Applications

Coarse 1000 micron screens are essential components in heavy-duty applications where large particles need to be filtered out efficiently. These screens are designed to withstand high pressure and heavy loads, making them ideal for industries such as mining, construction, and agriculture. However, in order to ensure the longevity and efficiency of these screens, proper maintenance is crucial.

One of the most important maintenance tips for coarse 1000 micron screens is regular cleaning. Over time, debris and particles can build up on the surface of the screen, reducing its effectiveness and potentially causing damage. To prevent this, it is recommended to clean the screen regularly using a soft brush or cloth to remove any buildup. In some cases, a mild detergent or cleaning solution may be necessary to remove stubborn residue.

In addition to regular cleaning, it is also important to inspect the screen for any signs of wear or damage. Cracks, tears, or holes in the screen can compromise its filtering capabilities and lead to costly repairs or replacements. By conducting routine inspections, any issues can be identified and addressed before they escalate.

Another key maintenance tip for coarse 1000 micron screens is proper storage when not in use. Screens should be stored in a clean, dry environment to prevent corrosion or damage. It is also important to store screens in a way that prevents them from being crushed or bent, as this can affect their performance.

When using coarse 1000 micron screens in heavy-duty applications, it is important to monitor their performance regularly. Changes in flow rate, pressure, or efficiency may indicate a problem with the screen that needs to be addressed. By keeping a close eye on the performance of the screen, any issues can be identified and resolved quickly.

In addition to regular maintenance, it is also important to follow the manufacturer’s guidelines for installation and operation of coarse 1000 micron screens. Improper installation or operation can lead to premature wear and damage, reducing the lifespan of the screen. By following the manufacturer’s recommendations, you can ensure that the screen performs optimally and lasts for as long as possible.

Overall, proper maintenance is essential for ensuring the longevity and efficiency of coarse 1000 micron screens in heavy-duty applications. By following these maintenance tips, you can extend the lifespan of your screens and maximize their performance. Regular cleaning, inspections, proper storage, monitoring performance, and following manufacturer guidelines are all key components of effective maintenance for coarse 1000 micron screens. By investing time and effort into maintaining your screens, you can avoid costly repairs and replacements and keep your operations running smoothly.