Table of Contents

Improved Filtration Efficiency

nylon mesh has become a popular choice for filter screening in air and liquid systems due to its numerous benefits. One of the key advantages of using nylon mesh is its improved filtration efficiency. This material is known for its ability to capture even the smallest particles, making it an ideal choice for applications where high levels of filtration are required.

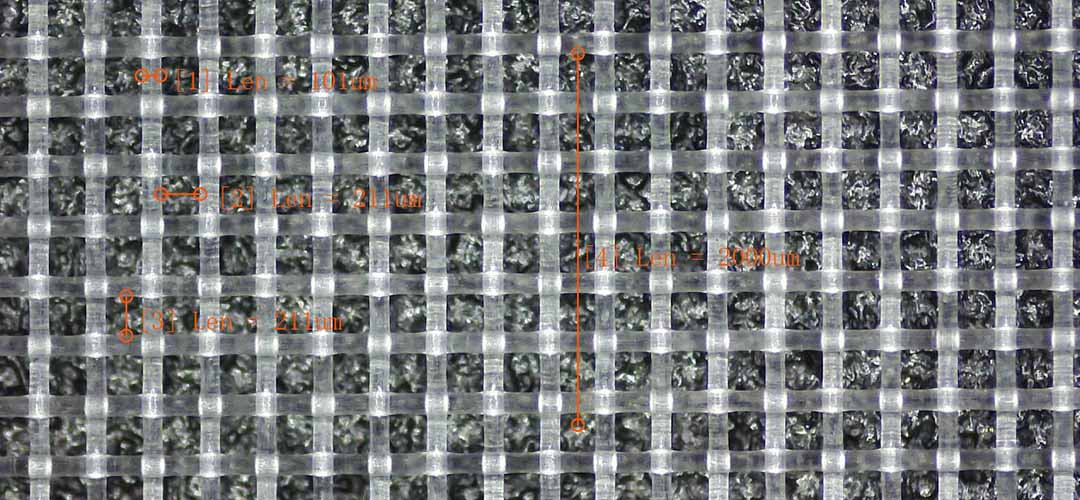

Nylon mesh is made from synthetic fibers that are woven together to create a fine mesh structure. This design allows for the efficient capture of particles while still allowing for the passage of air or liquid through the filter. The tight weave of nylon mesh ensures that even the tiniest particles are trapped, resulting in cleaner air or liquid on the other side.

In air filtration systems, nylon mesh is often used to capture dust, pollen, and other airborne particles that can be harmful to human health. By using nylon mesh filters, air quality can be significantly improved, creating a healthier and more comfortable environment for occupants. Additionally, the improved filtration efficiency of nylon mesh can help to extend the life of HVAC systems by reducing the amount of dust and debris that accumulates within the system.

In liquid filtration systems, nylon mesh is commonly used to remove impurities and contaminants from water, chemicals, and other liquids. The fine mesh structure of nylon filters allows for the efficient removal of particles, ensuring that the liquid remains clean and free of debris. This is particularly important in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where the purity of liquids is critical to the production process.

Another benefit of using nylon mesh for filter screening is its durability. Nylon is a strong and resilient material that can withstand high temperatures, chemicals, and mechanical stress. This makes nylon mesh filters ideal for use in harsh environments where other materials may degrade or fail. The longevity of nylon mesh filters can help to reduce maintenance costs and downtime, making them a cost-effective solution for filtration needs.

Furthermore, nylon mesh filters are easy to clean and maintain, making them a convenient option for businesses and industries that require frequent filter changes. The smooth surface of nylon mesh allows for easy removal of trapped particles, and the material can be washed or rinsed for reuse. This not only saves time and money but also reduces waste and environmental impact.

In conclusion, the benefits of using nylon mesh for filter screening in air and liquid systems are clear. From improved filtration efficiency to durability and ease of maintenance, nylon mesh filters offer a reliable and cost-effective solution for a wide range of filtration needs. By choosing nylon mesh filters, businesses and industries can ensure cleaner air and liquids, prolong the life of their equipment, and reduce maintenance costs in the long run.

Increased Durability and Longevity

Nylon mesh has become a popular choice for filter screening in air and liquid systems due to its numerous benefits. One of the key advantages of using nylon mesh is its increased durability and longevity compared to other materials. This makes it an ideal choice for applications where filters are subjected to high levels of wear and tear.

Nylon mesh is known for its strength and resilience, making it highly resistant to abrasion and tearing. This means that filters made from nylon mesh are less likely to become damaged or worn out over time, resulting in a longer lifespan and reduced maintenance costs. In addition, nylon mesh is also resistant to chemicals and corrosion, making it suitable for use in a wide range of environments.

Another benefit of nylon mesh is its flexibility and versatility. Nylon mesh can be easily customized to meet specific filtration requirements, allowing for the creation of filters with different mesh sizes and configurations. This flexibility makes nylon mesh filters suitable for a variety of applications, from fine particle filtration to coarse debris removal.

Furthermore, nylon mesh is lightweight and easy to handle, making it convenient to install and replace filters as needed. This can help to reduce downtime and maintenance costs, as filters can be quickly and easily swapped out without the need for specialized tools or equipment.

In addition to its durability and versatility, nylon mesh also offers excellent filtration performance. The fine mesh structure of nylon filters allows for efficient removal of particles and contaminants from air and liquid streams, ensuring that systems operate at optimal levels of performance and efficiency. This can help to improve the quality of air and liquid output, as well as extend the lifespan of equipment and machinery.

Overall, the benefits of using nylon mesh for filter screening in air and liquid systems are clear. Its increased durability and longevity, coupled with its flexibility and excellent filtration performance, make it a superior choice for a wide range of applications. By choosing nylon mesh filters, businesses can enjoy improved system performance, reduced maintenance costs, and increased operational efficiency.

In conclusion, nylon mesh offers a number of advantages for filter screening in air and liquid systems. Its durability, longevity, flexibility, and filtration performance make it a superior choice for a wide range of applications. Businesses looking to improve the performance and efficiency of their systems should consider the benefits of using nylon mesh filters.

Enhanced Air and Liquid Flow Rates

Nylon mesh is a versatile material that is commonly used in filter screening for air and liquid systems. Its unique properties make it an ideal choice for applications where enhanced flow rates are desired. In this article, we will explore the benefits of using nylon mesh for filter screening in air and liquid systems, specifically focusing on how it can improve flow rates.

One of the key advantages of nylon mesh is its ability to allow for increased airflow or liquid flow through the filter. The open weave design of nylon mesh allows for particles to be captured while still allowing air or liquid to pass through easily. This results in improved flow rates compared to other filter materials that may clog more easily.

Additionally, nylon mesh is a durable material that can withstand high flow rates without becoming damaged. This makes it an excellent choice for applications where a high volume of air or liquid needs to be filtered quickly and efficiently. The strength of nylon mesh also means that it can be used in a wide range of temperatures and environments without losing its effectiveness.

Another benefit of using nylon mesh for filter screening is its resistance to chemicals and corrosion. This makes it an ideal choice for applications where the filter may come into contact with harsh chemicals or corrosive liquids. Nylon mesh is also easy to clean and maintain, ensuring that it remains effective over time.

In addition to its durability and chemical resistance, nylon mesh is also a cost-effective option for filter screening in air and liquid systems. Its long lifespan and low maintenance requirements make it a cost-efficient choice for businesses looking to improve flow rates without breaking the bank. Nylon mesh is also readily available in a variety of sizes and configurations, making it easy to find the right filter for any application.

Overall, the benefits of using nylon mesh for filter screening in air and liquid systems are clear. Its ability to enhance flow rates, durability, chemical resistance, and cost-effectiveness make it a superior choice for businesses looking to improve their filtration processes. By choosing nylon mesh for filter screening, businesses can ensure that their air and liquid systems operate efficiently and effectively, leading to improved performance and productivity.

In conclusion, nylon mesh is a valuable material for filter screening in air and liquid systems. Its unique properties make it an ideal choice for applications where enhanced flow rates are desired. By utilizing nylon mesh for filter screening, businesses can improve their filtration processes, leading to increased efficiency and productivity.