Table of Contents

Filtration Systems

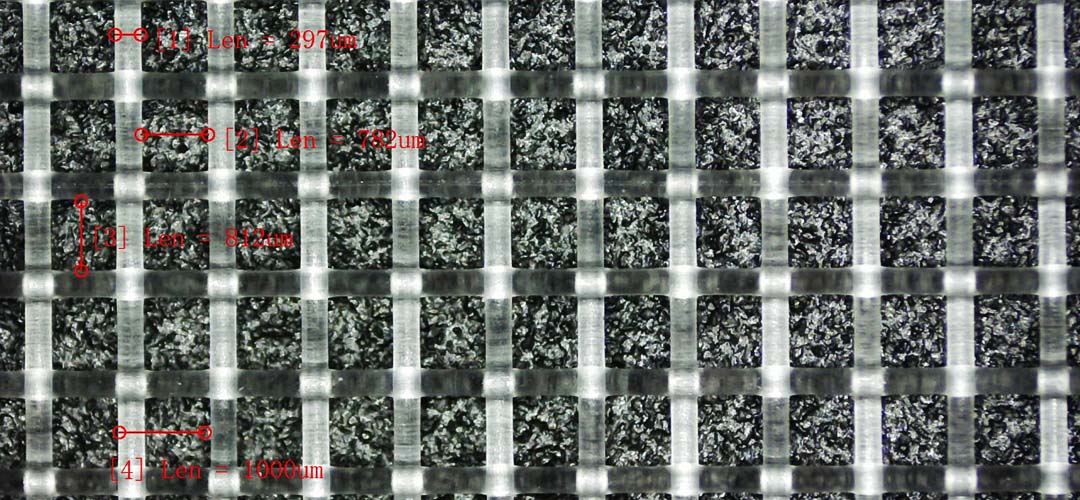

In the realm of filtration systems, the choice of materials plays a pivotal role in determining efficiency and effectiveness. Among the various options available, 80 micron nylon mesh has emerged as a preferred choice for numerous applications due to its unique properties and versatility. This particular mesh size strikes an optimal balance between filtration precision and flow rate, making it suitable for a wide array of industries, including food and beverage, pharmaceuticals, and water treatment.

One of the primary advantages of 80 micron nylon mesh is its ability to filter out particles while allowing liquids to pass through with minimal resistance. This characteristic is particularly beneficial in the food and beverage industry, where maintaining product quality is paramount. For instance, in brewing processes, this mesh can effectively separate hops and other solids from the liquid, ensuring a clear and consistent final product. Similarly, in juice production, it aids in removing pulp and sediment, resulting in a smoother texture that enhances consumer appeal. The durability of nylon mesh also means it can withstand the rigors of repeated use, making it a cost-effective solution for manufacturers.

Transitioning to the pharmaceutical sector, the importance of stringent filtration cannot be overstated. Here, 80 micron nylon mesh is utilized in various applications, including the filtration of active pharmaceutical ingredients (APIs) and excipients. The mesh’s fine filtration capabilities ensure that contaminants are effectively removed, thereby safeguarding product integrity and compliance with regulatory standards. Moreover, its chemical resistance allows it to be used in a variety of solvents and solutions, further broadening its applicability in this highly regulated industry. As pharmaceutical companies continue to prioritize quality assurance, the role of reliable filtration systems becomes increasingly critical, and 80 micron nylon mesh stands out as a trusted option.

In addition to food and pharmaceuticals, water treatment facilities also benefit significantly from the use of 80 micron nylon mesh. In these settings, the mesh is employed in pre-filtration processes to remove larger particles and debris from water sources before they undergo further purification. This initial filtration step is crucial, as it not only enhances the efficiency of subsequent treatment stages but also prolongs the lifespan of equipment by reducing wear and tear. Furthermore, the mesh’s ability to maintain high flow rates while providing effective filtration makes it an ideal choice for facilities that must process large volumes of water quickly and efficiently.

As industries continue to evolve and face new challenges, the demand for reliable filtration solutions remains constant. The versatility of 80 micron nylon mesh positions it as a key player in addressing these needs across various sectors. Its combination of durability, chemical resistance, and effective filtration capabilities ensures that it can meet the rigorous demands of modern applications. Additionally, as sustainability becomes a focal point for many businesses, the longevity and reusability of nylon mesh contribute to reducing waste and promoting environmentally friendly practices.

In conclusion, the applications of 80 micron nylon mesh in filtration systems are vast and varied, spanning multiple industries. Its ability to provide precise filtration while maintaining high flow rates makes it an invaluable asset in food and beverage production, pharmaceuticals, and water treatment. As companies seek to enhance their operational efficiency and product quality, the adoption of advanced filtration solutions like 80 micron nylon mesh will undoubtedly play a crucial role in their success.

Food Processing

In the realm of food processing, the choice of materials can significantly impact both efficiency and product quality. One such material that has gained prominence is 80 micron nylon mesh, which offers a unique combination of durability, flexibility, and filtration capabilities. This specific mesh size is particularly well-suited for various applications within the food industry, where hygiene and precision are paramount.

To begin with, 80 micron nylon mesh is widely utilized in the filtration of liquids, such as juices, sauces, and broths. Its fine mesh structure allows for the effective removal of particulates while ensuring that the desired flavors and nutrients remain intact. This is crucial in maintaining the quality of the final product, as any unwanted debris can compromise both taste and safety. Moreover, the nylon material is resistant to a range of chemicals, making it ideal for use in environments where cleaning agents are frequently employed. This resistance not only extends the lifespan of the mesh but also ensures that it does not leach harmful substances into food products.

In addition to filtration, 80 micron nylon mesh plays a vital role in the production of various food items through processes such as sieving and straining. For instance, in the preparation of fine flours or powdered ingredients, this mesh can effectively separate larger particles, resulting in a more consistent and high-quality end product. The ability to achieve such precision is essential in food processing, where even minor variations can lead to significant differences in texture and flavor. Furthermore, the lightweight nature of nylon mesh facilitates easy handling and installation, allowing food processors to integrate it seamlessly into their existing systems.

Another noteworthy application of 80 micron nylon mesh is in the realm of food packaging. The mesh can be employed in the creation of breathable bags or pouches that allow for air circulation while protecting the contents from contaminants. This is particularly beneficial for products such as fresh produce, where maintaining freshness and preventing spoilage are critical. By utilizing nylon mesh in packaging, food processors can enhance the shelf life of their products, ultimately leading to reduced waste and increased customer satisfaction.

Moreover, the versatility of 80 micron nylon mesh extends to its use in the production of dairy products. In cheese-making, for example, the mesh is instrumental in separating curds from whey, ensuring that the final product has the desired texture and moisture content. The fine mesh size allows for optimal drainage while retaining the essential components of the cheese, thereby enhancing its flavor profile. This application underscores the importance of selecting the right mesh size in achieving specific culinary outcomes.

As the food processing industry continues to evolve, the demand for materials that can meet stringent safety and quality standards is ever-increasing. 80 micron nylon mesh stands out as a reliable solution that not only meets these requirements but also offers additional benefits such as ease of cleaning and reusability. Its applications in filtration, sieving, packaging, and dairy production highlight its versatility and effectiveness in enhancing food processing operations.

In conclusion, the integration of 80 micron nylon mesh into food processing applications represents a strategic choice for businesses aiming to optimize their production processes. By leveraging its unique properties, food processors can ensure that they deliver high-quality products that meet consumer expectations while adhering to industry regulations. As the landscape of food processing continues to change, the role of innovative materials like nylon mesh will undoubtedly become increasingly significant.

Pharmaceutical Manufacturing

In the realm of pharmaceutical manufacturing, precision and reliability are paramount. One material that has gained significant traction in this industry is the 80 micron nylon mesh. This specialized mesh offers a unique combination of properties that make it particularly well-suited for various applications within the pharmaceutical sector. Its fine filtration capabilities, chemical resistance, and durability position it as an essential component in processes ranging from drug formulation to quality control.

To begin with, the 80 micron nylon mesh is widely utilized in the filtration of active pharmaceutical ingredients (APIs). The mesh’s precise pore size allows for the effective separation of particulates from liquids, ensuring that the final product is free from contaminants. This is crucial, as even minute impurities can compromise the efficacy and safety of pharmaceutical products. By employing 80 micron nylon mesh in the filtration process, manufacturers can achieve a higher level of purity, which is a critical requirement in the production of medications.

Moreover, the chemical resistance of nylon mesh enhances its applicability in pharmaceutical manufacturing. The mesh can withstand exposure to a variety of solvents and chemicals commonly used in drug formulation processes. This characteristic not only extends the lifespan of the mesh but also ensures that it does not leach harmful substances into the products being processed. Consequently, manufacturers can maintain compliance with stringent regulatory standards while safeguarding the integrity of their formulations.

In addition to filtration, 80 micron nylon mesh plays a vital role in the encapsulation of pharmaceuticals. The mesh is often used in the production of capsules, where it serves as a barrier that allows for the controlled release of active ingredients. This application is particularly important in the development of sustained-release formulations, which are designed to deliver medication over an extended period. By utilizing nylon mesh, manufacturers can optimize the release profiles of their products, thereby enhancing therapeutic outcomes for patients.

Furthermore, the durability of 80 micron nylon mesh makes it an ideal choice for various manufacturing processes. Unlike other materials that may degrade or become ineffective over time, nylon mesh maintains its structural integrity even under rigorous conditions. This resilience is particularly beneficial in high-volume production environments, where consistent performance is essential. As a result, manufacturers can rely on nylon mesh to deliver reliable results, minimizing downtime and maximizing productivity.

Transitioning from production to quality control, the 80 micron nylon mesh also finds its place in laboratory settings. It is frequently employed in the testing of pharmaceutical products, where it aids in the filtration of samples prior to analysis. This step is critical in ensuring that the samples are representative and free from extraneous materials that could skew results. By incorporating nylon mesh into their testing protocols, laboratories can enhance the accuracy and reliability of their findings, ultimately contributing to the overall quality of the pharmaceutical products being developed.

In conclusion, the applications of 80 micron nylon mesh in pharmaceutical manufacturing are diverse and impactful. From filtration and encapsulation to quality control, its unique properties make it an indispensable tool in the industry. As pharmaceutical manufacturers continue to seek ways to improve efficiency and product quality, the role of nylon mesh is likely to expand further, solidifying its position as a cornerstone of modern pharmaceutical production. By leveraging the advantages offered by this material, manufacturers can not only meet regulatory requirements but also enhance patient safety and therapeutic efficacy.