Table of Contents

Benefits of Using Versatile micron filter cloth in Industrial Processes

Micron filter cloth is an essential component in many industrial and commercial processes. Its versatility and effectiveness make it a valuable tool for a wide range of applications. In this article, we will explore the benefits of using versatile micron filter cloth in industrial processes.

One of the key advantages of micron filter cloth is its ability to effectively remove contaminants from liquids and gases. The tight weave of the cloth allows it to capture particles as small as one micron in size, making it ideal for filtering out impurities in a variety of substances. This level of filtration is crucial in industries such as pharmaceuticals, food and beverage, and water treatment, where purity and cleanliness are paramount.

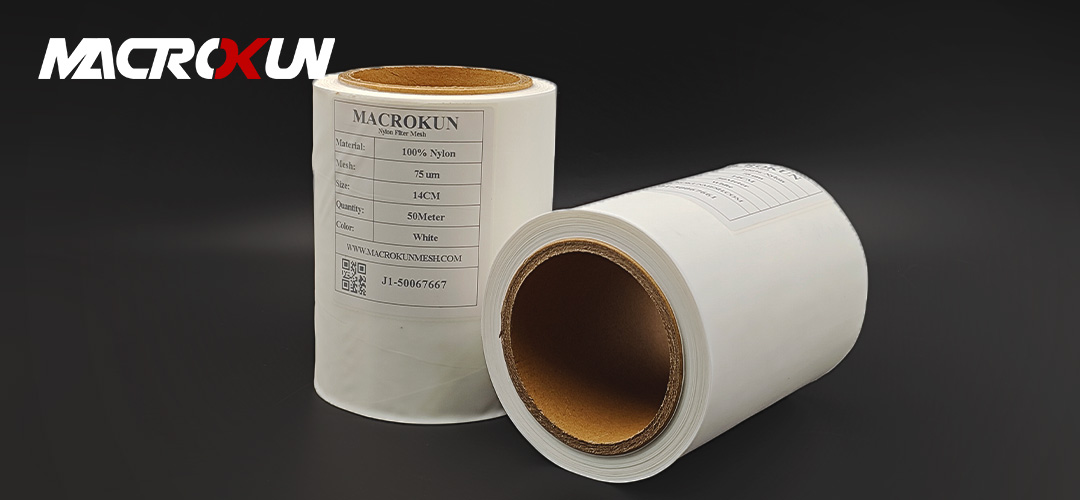

In addition to its superior filtration capabilities, micron filter cloth is also highly durable and long-lasting. Made from high-quality materials such as polyester, polypropylene, and nylon, this type of filter cloth can withstand harsh chemicals, high temperatures, and heavy use without losing its effectiveness. This durability makes it a cost-effective solution for industrial processes that require frequent filtration.

Another benefit of using micron filter cloth is its versatility. Available in a wide range of pore sizes and materials, this type of filter cloth can be customized to meet the specific needs of different industries and applications. Whether you need to filter out large particles or tiny contaminants, there is a micron filter cloth that can do the job effectively.

Furthermore, micron filter cloth is easy to install and maintain, making it a convenient choice for busy industrial facilities. With proper care and cleaning, this type of filter cloth can last for years, providing reliable filtration and cost savings over time. Its ease of use and low maintenance requirements make it a practical choice for businesses looking to streamline their filtration processes.

In conclusion, versatile micron filter cloth offers a range of benefits for industrial and commercial applications. From its superior filtration capabilities to its durability and ease of use, this type of filter cloth is a valuable tool for businesses in a variety of industries. By investing in high-quality micron filter cloth, companies can improve the efficiency and effectiveness of their filtration processes, leading to better quality products and cost savings in the long run.

How to Choose the Right Micron Filter Cloth for Your Commercial Application

Micron filter cloth is an essential component in many industrial and commercial applications. It plays a crucial role in separating solids from liquids, ensuring the purity and quality of the final product. With a wide range of micron filter cloths available on the market, choosing the right one for your specific commercial application can be a daunting task. In this article, we will discuss the factors to consider when selecting a micron filter cloth and how to ensure that you choose the right one for your needs.

One of the most important factors to consider when choosing a micron filter cloth is the micron rating. The micron rating refers to the size of the particles that the filter cloth can effectively capture. The lower the micron rating, the smaller the particles that the filter cloth can capture. For applications that require a high level of filtration, such as pharmaceutical or food processing, a filter cloth with a lower micron rating is essential. On the other hand, for applications that require a coarser filtration, such as wastewater treatment, a filter cloth with a higher micron rating may be more suitable.

Another important factor to consider when choosing a micron filter cloth is the material of construction. Micron filter cloths are typically made from materials such as polyester, polypropylene, nylon, or PTFE. Each material has its own unique properties and is suitable for different applications. For example, polyester filter cloths are known for their durability and resistance to chemicals, making them ideal for applications that involve harsh chemicals. On the other hand, polypropylene filter cloths are lightweight and cost-effective, making them a popular choice for general filtration applications.

In addition to the micron rating and material of construction, it is also important to consider the weave of the filter cloth. The weave of the filter cloth refers to the pattern in which the fibers are arranged. Common weave patterns include plain weave, twill weave, and satin weave. Each weave pattern has its own unique characteristics and is suitable for different applications. For example, plain weave filter cloths are known for their high flow rates and good particle retention, making them ideal for applications that require a high level of filtration efficiency.

When choosing a micron filter cloth for your commercial application, it is important to consider the specific requirements of your application. Consider factors such as the type of particles that need to be filtered, the flow rate of the liquid, and the operating conditions of the filtration system. By taking these factors into account, you can ensure that you choose a micron filter cloth that is tailored to meet the needs of your application.

In conclusion, choosing the right micron filter cloth for your commercial application is essential to ensure the efficiency and effectiveness of your filtration system. By considering factors such as the micron rating, material of construction, and weave pattern, you can select a filter cloth that is best suited to meet the requirements of your application. With the right micron filter cloth in place, you can achieve optimal filtration performance and ensure the quality and purity of your final product.

Case Studies: Successful Implementation of Micron Filter Cloth in Various Industries

Micron filter cloth is a versatile and essential component in various industries, providing an effective solution for separating solids from liquids. Its ability to capture particles of different sizes makes it a valuable tool for industrial and commercial applications. In this article, we will explore some case studies that demonstrate the successful implementation of micron filter cloth in different industries.

One of the industries that have benefited greatly from the use of micron filter cloth is the pharmaceutical industry. In pharmaceutical manufacturing, maintaining a high level of cleanliness and purity is crucial to ensure the safety and efficacy of the final product. Micron filter cloth is used in filtration processes to remove impurities and contaminants from liquids, ensuring that the end product meets the required quality standards. By using micron filter cloth, pharmaceutical companies can achieve a higher level of product purity and consistency, leading to improved product quality and customer satisfaction.

Another industry that has seen significant benefits from the use of micron filter cloth is the food and beverage industry. In food and beverage production, maintaining a clean and hygienic environment is essential to prevent contamination and ensure product safety. Micron filter cloth is used in filtration processes to remove particles and impurities from liquids, such as juices, syrups, and sauces. By using micron filter cloth, food and beverage manufacturers can improve the quality and clarity of their products, leading to increased consumer confidence and brand loyalty.

The automotive industry is another sector that has successfully implemented micron filter cloth in its manufacturing processes. In automotive manufacturing, the use of micron filter cloth is essential for removing contaminants and impurities from lubricants, coolants, and other fluids used in the production process. By using micron filter cloth, automotive manufacturers can ensure that their products meet the required quality standards and performance specifications, leading to improved product reliability and longevity.

In the mining and mineral processing industry, micron filter cloth plays a crucial role in separating solids from liquids during the extraction and processing of ores and minerals. By using micron filter cloth, mining companies can effectively remove impurities and contaminants from process liquids, ensuring that the final product meets the required purity and quality standards. This results in improved efficiency and productivity in the mining and mineral processing operations, leading to cost savings and increased profitability.

Overall, the successful implementation of micron filter cloth in various industries demonstrates its versatility and effectiveness in separating solids from liquids. By using micron filter cloth, companies can improve product quality, consistency, and reliability, leading to increased customer satisfaction and brand loyalty. As technology continues to advance, the demand for micron filter cloth is expected to grow, making it an essential component in industrial and commercial applications.