Table of Contents

Benefits of Using 5 micron stainless steel mesh filter in Industrial Applications

In industrial applications where precision and durability are paramount, the 5 micron stainless steel mesh filter stands out as a reliable and effective solution. This type of filter is designed to remove particles as small as 5 microns from liquids or gases, making it ideal for a wide range of industries, including pharmaceuticals, food and beverage, petrochemical, and more.

One of the key benefits of using a 5 micron stainless steel mesh filter is its durability. Made from high-quality stainless steel, this type of filter is resistant to corrosion, abrasion, and high temperatures, making it suitable for even the most demanding industrial environments. Unlike other types of filters that may need frequent replacement due to wear and tear, a 5 micron stainless steel mesh filter can withstand the rigors of continuous use, saving time and money in the long run.

Another advantage of using a 5 micron stainless steel mesh filter is its precision. With the ability to capture particles as small as 5 microns, this type of filter ensures that only clean and pure liquids or gases pass through, resulting in higher product quality and consistency. Whether it’s removing contaminants from pharmaceutical products or ensuring the purity of food and beverage ingredients, a 5 micron stainless steel mesh filter delivers precise filtration that meets the strictest industry standards.

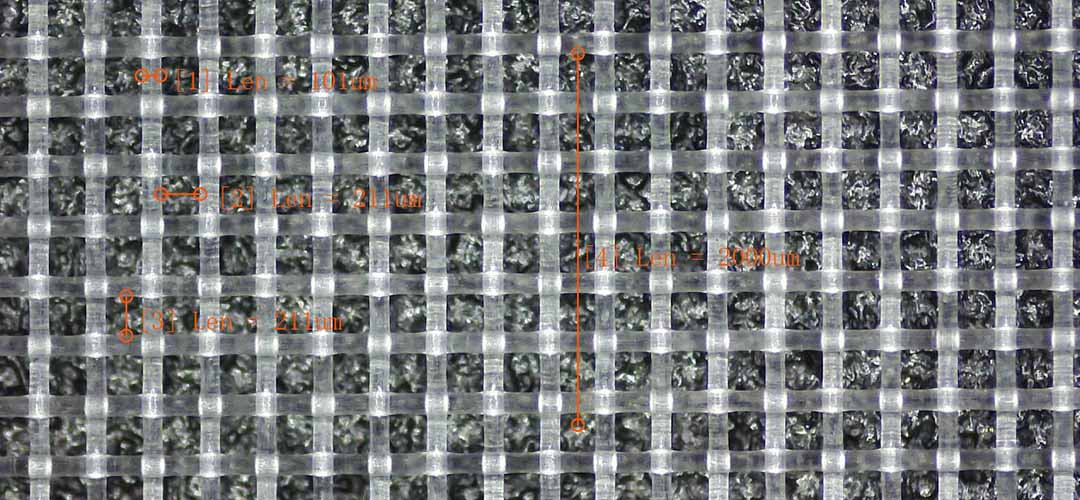

Furthermore, the design of a 5 micron stainless steel mesh filter allows for efficient and effective filtration. The mesh material is woven in a way that maximizes surface area and flow rate, ensuring that particles are captured without impeding the flow of liquids or gases. This means that industrial processes can run smoothly and efficiently, with minimal downtime or interruptions due to clogged filters.

Additionally, a 5 micron stainless steel mesh filter is easy to clean and maintain, further enhancing its cost-effectiveness and convenience. Unlike disposable filters that need to be replaced frequently, a stainless steel mesh filter can be cleaned and reused multiple times, reducing waste and saving money on filter replacements. With proper care and maintenance, a 5 micron stainless steel mesh filter can last for years, providing reliable filtration performance for the long term.

In conclusion, the 5 micron stainless steel mesh filter offers a range of benefits for industrial applications, including durability, precision, efficiency, and cost-effectiveness. By choosing this type of filter, industries can ensure the quality and purity of their products while also saving time and money on filter replacements. With its ability to withstand harsh conditions and deliver precise filtration, the 5 micron stainless steel mesh filter is a valuable asset for any industrial operation that values reliability and performance.

How to Properly Maintain and Clean a 5 Micron Stainless Steel Mesh Filter

A 5 micron stainless steel mesh filter is a crucial component in many industrial and commercial applications. Its ability to effectively filter out particles as small as 5 microns makes it an essential tool for ensuring the quality and purity of liquids and gases. However, like any piece of equipment, proper maintenance and cleaning are necessary to ensure optimal performance and longevity.

One of the key benefits of a 5 micron stainless steel mesh filter is its durability. Made from high-quality stainless steel, these filters are designed to withstand harsh conditions and heavy use. Despite their robust construction, regular maintenance is still required to keep them operating at peak efficiency.

To properly maintain a 5 micron stainless steel mesh filter, it is important to regularly inspect the filter for any signs of damage or wear. This includes checking for tears or holes in the mesh, as well as ensuring that the frame and housing are in good condition. Any damage should be repaired or replaced immediately to prevent contaminants from bypassing the filter.

In addition to visual inspections, it is also important to regularly clean the filter to remove any buildup of debris or contaminants. This can be done by soaking the filter in a cleaning solution or using a pressure washer to remove stubborn particles. It is important to follow the manufacturer’s recommendations for cleaning to avoid damaging the filter.

When cleaning a 5 micron stainless steel mesh filter, it is important to use the proper tools and techniques to avoid damaging the filter. Avoid using harsh chemicals or abrasive materials that can corrode or scratch the stainless steel mesh. Instead, use a mild detergent or cleaning solution and a soft brush to gently scrub away any buildup.

After cleaning, it is important to thoroughly rinse the filter to remove any residue from the cleaning solution. This will help prevent contamination of the liquid or gas being filtered. Once the filter is clean and dry, it can be reinstalled and put back into service.

Regular maintenance and cleaning of a 5 micron stainless steel mesh filter are essential for ensuring its longevity and effectiveness. By following these simple steps, you can keep your filter operating at peak performance and avoid costly repairs or replacements. Remember to inspect the filter regularly, clean it properly, and follow the manufacturer’s recommendations for maintenance. With proper care, your 5 micron stainless steel mesh filter will continue to provide reliable filtration for years to come.

Comparing the Efficiency and Longevity of 5 Micron Stainless Steel Mesh Filter with Other Filter Types

When it comes to filtration systems, the 5 micron stainless steel mesh filter stands out as a durable and precise option. This type of filter is designed to remove particles as small as 5 microns from a liquid or gas stream, making it ideal for a wide range of applications. In this article, we will compare the efficiency and longevity of the 5 micron stainless steel mesh filter with other filter types to highlight its superior performance.

One of the key advantages of the 5 micron stainless steel mesh filter is its high level of efficiency. The small mesh size of 5 microns allows the filter to capture even the tiniest particles, ensuring that the filtered liquid or gas is free from contaminants. This level of precision is essential in industries where purity is paramount, such as pharmaceuticals, food and beverage, and electronics manufacturing.

In comparison, other filter types may not be able to achieve the same level of filtration efficiency. For example, paper filters are commonly used in household appliances like coffee makers, but they are not suitable for industrial applications that require a higher level of filtration. Paper filters can easily tear or clog, leading to a decrease in filtration efficiency over time.

Another advantage of the 5 micron stainless steel mesh filter is its durability. Stainless steel is known for its strength and corrosion resistance, making it an ideal material for filters that are exposed to harsh operating conditions. The mesh filter can withstand high temperatures, pressure, and chemical exposure without losing its effectiveness, ensuring a long service life.

In contrast, filters made from materials like paper or plastic are more prone to damage and degradation. Paper filters can tear easily, while plastic filters may warp or break under extreme conditions. This can result in frequent filter replacements and increased maintenance costs, making them less cost-effective in the long run.

The longevity of the 5 micron stainless steel mesh filter is further enhanced by its ease of cleaning and maintenance. Unlike disposable filters that need to be replaced regularly, the stainless steel mesh filter can be cleaned and reused multiple times. This not only reduces operating costs but also minimizes waste and environmental impact.

On the other hand, disposable filters contribute to landfill waste and require frequent replacements, adding to the overall cost of filtration systems. In addition, the cleaning process for stainless steel mesh filters is simple and straightforward, requiring only basic equipment and minimal downtime.

Overall, the 5 micron stainless steel mesh filter offers a combination of efficiency, durability, and cost-effectiveness that sets it apart from other filter types. Its ability to capture small particles with precision, withstand harsh conditions, and provide long-lasting performance makes it an ideal choice for a wide range of industrial applications.

In conclusion, the 5 micron stainless steel mesh filter is a reliable and efficient filtration solution that outperforms other filter types in terms of longevity and performance. Its durability, precision, and cost-effectiveness make it a valuable investment for industries that require high-quality filtration.