Table of Contents

Importance of Micron Filter Mesh size in Industrial Applications

Micron filter mesh size plays a crucial role in various industrial applications, as it determines the level of filtration and separation that can be achieved. Choosing the right micron filter mesh size is essential to ensure optimal performance and efficiency in your processes. In this article, we will discuss the importance of micron filter mesh size in industrial applications and provide guidance on how to choose the perfect fit for your specific needs.

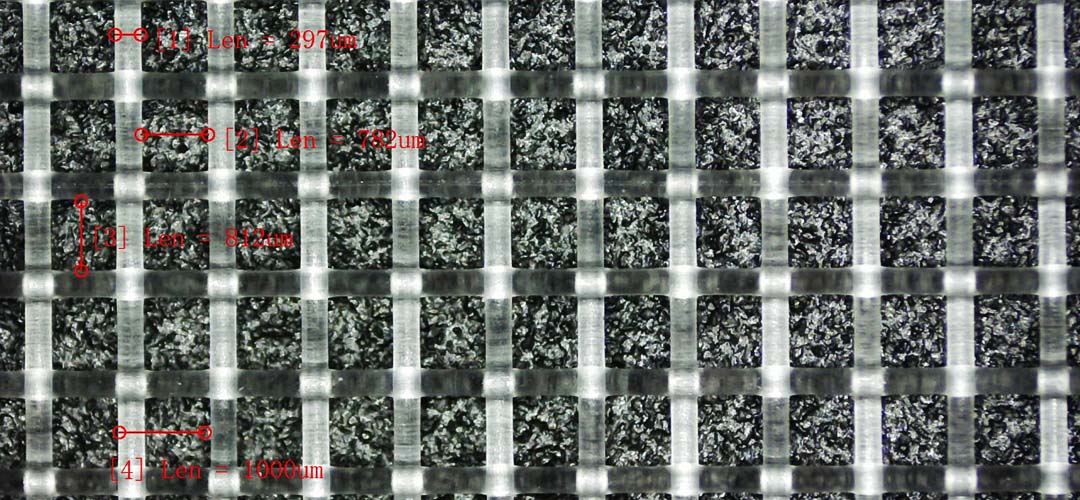

One of the key factors to consider when selecting a micron filter mesh size is the particle size of the material you are trying to filter. The micron filter mesh size refers to the size of the openings in the mesh, which determines the size of particles that can pass through. For example, if you are filtering large particles, you will need a mesh with larger openings, while smaller particles will require a finer mesh with smaller openings.

Another important consideration is the flow rate of the material being filtered. A mesh with smaller openings will provide greater filtration efficiency but may also restrict the flow of material, leading to slower processing times. On the other hand, a mesh with larger openings will allow for faster flow rates but may not provide as thorough filtration. It is essential to strike a balance between filtration efficiency and flow rate to achieve optimal performance.

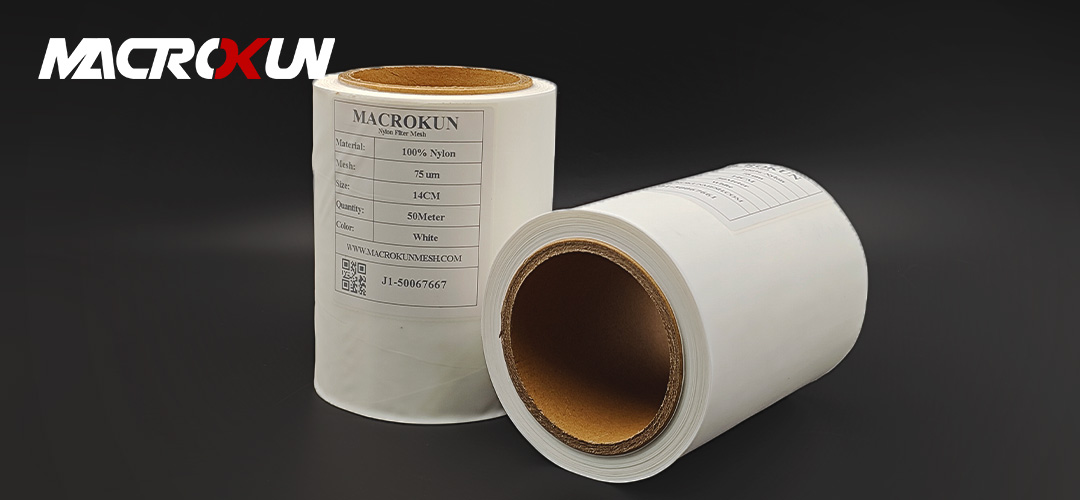

The material of the mesh is also a critical factor to consider when choosing a micron filter mesh size. Different materials have varying levels of durability, chemical resistance, and temperature tolerance. For example, stainless steel mesh is highly durable and resistant to corrosion, making it suitable for harsh industrial environments. In contrast, nylon mesh is lightweight and flexible but may not be as durable as stainless steel. It is essential to select a mesh material that is compatible with the specific requirements of your application.

In addition to particle size, flow rate, and material, the shape of the particles being filtered should also be taken into account when selecting a micron filter mesh size. Irregularly shaped particles may require a finer mesh to ensure thorough filtration, while spherical particles may be effectively filtered using a coarser mesh. Understanding the characteristics of the particles being filtered will help you choose the most appropriate mesh size for your application.

When choosing a micron filter mesh size, it is essential to consider the desired level of filtration efficiency and the specific requirements of your application. Conducting thorough testing and analysis of the material being filtered will help you determine the optimal mesh size for your needs. It is also advisable to consult with a filtration expert to ensure that you are selecting the right micron filter mesh size for your application.

In conclusion, micron filter mesh size is a critical factor in achieving optimal filtration and separation in industrial applications. By considering factors such as particle size, flow rate, material, and particle shape, you can choose the perfect fit for your specific needs. Selecting the right micron filter mesh size will help you improve efficiency, reduce downtime, and enhance the overall performance of your processes.

Factors to Consider When Selecting Micron Filter Mesh Size

When it comes to selecting the right micron filter mesh size for your application, there are several factors to consider in order to ensure optimal performance. The micron filter mesh size plays a crucial role in determining the efficiency and effectiveness of the filtration process. Choosing the right size will help you achieve the desired level of filtration and ensure that your equipment operates at its best.

One of the key factors to consider when selecting a micron filter mesh size is the type of particles you are trying to filter. Different particles require different mesh sizes to effectively capture and remove them from the fluid or gas being filtered. For example, if you are filtering large particles, you will need a larger mesh size to allow them to pass through while capturing smaller particles. On the other hand, if you are filtering very fine particles, you will need a smaller mesh size to ensure that they are effectively captured.

Another important factor to consider is the flow rate of the fluid or gas being filtered. The micron filter mesh size will impact the flow rate by determining how easily the fluid or gas can pass through the filter. A smaller mesh size will result in a slower flow rate as the particles have to pass through smaller openings, while a larger mesh size will allow for a faster flow rate. It is important to strike a balance between filtration efficiency and flow rate to ensure that your equipment operates efficiently.

The material of the micron filter mesh is also an important consideration when selecting the right size. Different materials have different properties that can impact the filtration process. For example, stainless steel mesh is durable and resistant to corrosion, making it ideal for applications where the filter will be exposed to harsh conditions. On the other hand, nylon mesh is lightweight and flexible, making it suitable for applications where flexibility is important.

In addition to the material of the mesh, the construction of the filter also plays a role in determining the appropriate micron filter mesh size. The weave pattern of the mesh can impact the filtration efficiency and flow rate. For example, a plain weave mesh has a simple crisscross pattern that allows for good flow rates but may not be as effective at capturing fine particles. On the other hand, a twill weave mesh has a more complex pattern that provides better filtration efficiency but may result in a slower flow rate.

When selecting the right micron filter mesh size, it is important to consider the specific requirements of your application. By taking into account factors such as the type of particles being filtered, the flow rate, the material of the mesh, and the construction of the filter, you can choose the perfect fit for your needs. Investing in the right micron filter mesh size will help you achieve optimal filtration performance and ensure that your equipment operates at its best.

Comparison of different micron filter mesh Sizes and Their Applications

When it comes to choosing the right micron filter mesh size for your application, there are several factors to consider. The micron filter mesh size refers to the size of the openings in the mesh, which determines the size of particles that can pass through. Choosing the right micron filter mesh size is crucial to ensure that your filtration system is effective in removing contaminants and achieving the desired level of filtration.

One of the key factors to consider when choosing a micron filter mesh size is the size of the particles you want to remove. The smaller the micron filter mesh size, the smaller the particles it can capture. For example, a micron filter mesh size of 100 microns will capture larger particles than a micron filter mesh size of 50 microns. Therefore, it is important to consider the size of the particles you want to remove when selecting a micron filter mesh size.

Another factor to consider when choosing a micron filter mesh size is the flow rate of your filtration system. A smaller micron filter mesh size will result in a slower flow rate, as the smaller openings in the mesh restrict the flow of liquid through the filter. On the other hand, a larger micron filter mesh size will allow for a faster flow rate, but may not capture smaller particles effectively. It is important to strike a balance between filtration efficiency and flow rate when selecting a micron filter mesh size.

In addition to particle size and flow rate, the type of application also plays a role in determining the appropriate micron filter mesh size. For example, in applications where fine particles need to be removed, such as in pharmaceutical or food processing industries, a smaller micron filter mesh size may be required. On the other hand, in applications where larger particles need to be removed, such as in wastewater treatment or industrial filtration, a larger micron filter mesh size may be more suitable.

It is also important to consider the material of the micron filter mesh when choosing a filter size. Different materials have different properties that can affect the filtration efficiency and durability of the filter. For example, stainless steel mesh is durable and resistant to corrosion, making it suitable for applications where the filter will be exposed to harsh conditions. On the other hand, nylon mesh is lightweight and flexible, making it ideal for applications where flexibility is required.

In conclusion, choosing the right micron filter mesh size is essential to ensure that your filtration system is effective in removing contaminants and achieving the desired level of filtration. Factors such as particle size, flow rate, application type, and material should be taken into consideration when selecting a micron filter mesh size. By carefully considering these factors, you can choose the perfect fit for your application and ensure that your filtration system operates efficiently and effectively.