Table of Contents

Benefits of Using 20 Micron Screens for Fine Particle Filtration

Fine particle filtration is a critical process in many industries, from pharmaceuticals to food and beverage production. Ensuring that particles as small as 20 microns are effectively removed from liquids is essential for maintaining product quality and meeting regulatory standards. One of the most effective tools for achieving this level of filtration is the 20 micron screen.

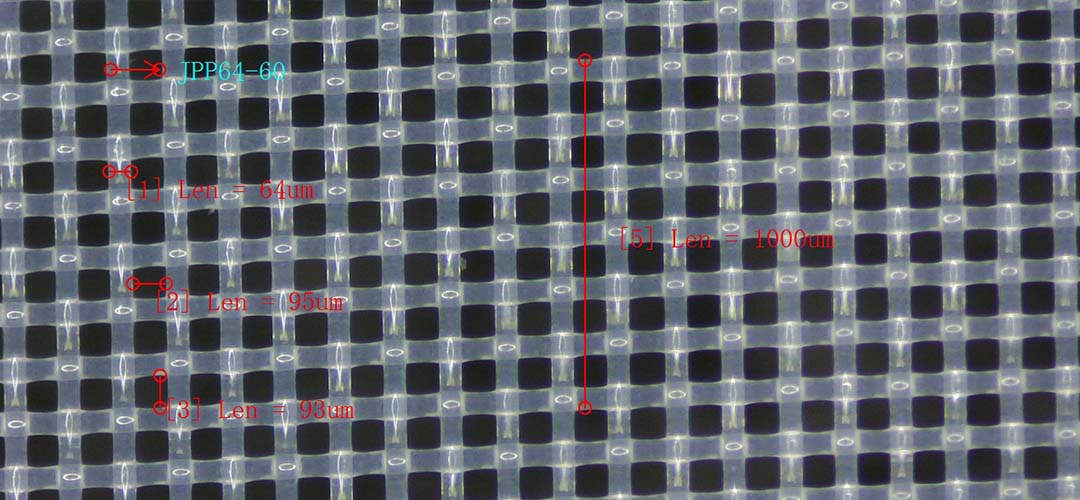

20 micron screens are designed to capture particles that are 20 microns or larger in size, making them ideal for applications where fine particle removal is necessary. These screens are typically made from durable materials such as stainless steel or polypropylene, ensuring that they can withstand the rigors of industrial use.

One of the key benefits of using a 20 micron screen for fine particle filtration is its high level of efficiency. These screens are able to capture a wide range of particle sizes, ensuring that even the smallest contaminants are removed from the liquid being filtered. This level of filtration is essential for industries where product purity is paramount, such as pharmaceutical manufacturing or semiconductor production.

In addition to their high level of efficiency, 20 micron screens are also highly versatile. They can be used in a wide range of applications, from filtering water and chemicals to removing impurities from food and beverages. This versatility makes them a valuable tool for any industry that requires fine particle filtration.

Another benefit of using a 20 micron screen is its ease of maintenance. These screens are designed to be easily cleaned and maintained, ensuring that they can continue to provide effective filtration over time. This reduces downtime and maintenance costs, making them a cost-effective solution for businesses looking to improve their filtration processes.

Furthermore, 20 micron screens are highly durable, ensuring that they can withstand the demands of industrial use. Whether they are being used in a high-pressure filtration system or in a corrosive environment, these screens are able to maintain their effectiveness over time. This durability makes them a reliable choice for businesses looking to invest in long-lasting filtration solutions.

In conclusion, 20 micron screens are a perfect solution for fine particle filtration in a wide range of industries. Their high level of efficiency, versatility, ease of maintenance, and durability make them an ideal choice for businesses looking to improve their filtration processes. By investing in a 20 micron screen, businesses can ensure that their products meet the highest standards of purity and quality, while also reducing maintenance costs and downtime.

How to Choose the Right 20 Micron Screen for Your Filtration Needs

When it comes to fine particle filtration, a 20 micron screen is often the perfect solution. With its ability to capture particles as small as 20 microns in size, this type of screen is widely used in various industries, including pharmaceuticals, food and beverage, and water treatment. However, choosing the right 20 micron screen for your specific filtration needs can be a daunting task. In this article, we will guide you through the process of selecting the perfect 20 micron screen, ensuring that you make an informed decision.

First and foremost, it is important to understand the different types of 20 micron screens available in the market. There are various materials used to manufacture these screens, including stainless steel, nylon, and polyester. Each material has its own set of advantages and disadvantages, so it is crucial to consider the specific requirements of your filtration process. Stainless steel screens, for example, are known for their durability and resistance to corrosion, making them ideal for applications that involve harsh chemicals or high temperatures. On the other hand, nylon screens are more affordable and offer excellent chemical resistance, making them suitable for a wide range of filtration needs.

Another important factor to consider when choosing a 20 micron screen is the type of weave. The weave pattern determines the size and shape of the openings in the screen, which directly affects its filtration efficiency. Common weave patterns include plain weave, twill weave, and Dutch weave. Plain weave screens have a simple crisscross pattern and offer good strength and filtration efficiency. Twill weave screens, on the other hand, have a diagonal pattern that provides better strength and filtration performance. Dutch weave screens have a complex weave pattern that allows for precise filtration, making them ideal for applications that require high precision.

In addition to material and weave pattern, it is essential to consider the size and shape of the screen. The size of the screen should be compatible with your filtration system, ensuring a proper fit and efficient filtration. The shape of the screen, whether it is round, rectangular, or custom-shaped, should also be considered based on the specific requirements of your filtration process.

Furthermore, it is crucial to evaluate the flow rate and pressure drop of the 20 micron screen. The flow rate refers to the amount of fluid that can pass through the screen per unit of time, while the pressure drop is the decrease in pressure across the screen. These factors are important to ensure that the screen can handle the desired flow rate without causing excessive pressure drop, which can negatively impact the efficiency of your filtration system.

Lastly, it is advisable to consult with a reputable supplier or manufacturer when choosing a 20 micron screen. They can provide valuable insights and recommendations based on their expertise and experience. Additionally, they can offer customized solutions to meet your specific filtration needs, ensuring optimal performance and efficiency.

In conclusion, selecting the right 20 micron screen for your filtration needs requires careful consideration of various factors, including material, weave pattern, size and shape, flow rate, and pressure drop. By taking the time to evaluate these factors and consulting with experts, you can ensure that you make an informed decision and choose a 20 micron screen that will effectively capture fine particles and meet your filtration requirements.

Case Studies: Successful Applications of 20 Micron Screens in Various Industries

In the world of filtration, finding the right solution for fine particle filtration can be a challenging task. However, the 20 micron screen has proven to be a perfect solution for many industries looking to effectively remove small particles from their processes. In this article, we will explore successful applications of 20 micron screens in various industries, highlighting their effectiveness and versatility.

One industry that has benefited greatly from the use of 20 micron screens is the food and beverage industry. In this industry, maintaining high levels of cleanliness and hygiene is crucial to ensuring the safety of the products being produced. 20 micron screens are able to effectively remove small particles such as dirt, debris, and bacteria from liquids and gases, helping to maintain the quality and purity of the final product. By using 20 micron screens in their filtration processes, food and beverage manufacturers can ensure that their products meet the highest standards of quality and safety.

Another industry that has seen success with the use of 20 micron screens is the pharmaceutical industry. In this highly regulated industry, maintaining precise levels of filtration is essential to ensuring the safety and efficacy of pharmaceutical products. 20 micron screens are able to provide the level of filtration needed to remove small particles and impurities from pharmaceutical compounds, helping to ensure that the final product is pure and free from contaminants. By incorporating 20 micron screens into their filtration processes, pharmaceutical companies can meet regulatory requirements and produce high-quality products that meet the needs of their customers.

The automotive industry is another sector that has found success with the use of 20 micron screens. In this industry, precision and efficiency are key factors in the manufacturing process. 20 micron screens are able to effectively remove small particles such as metal shavings, dirt, and debris from lubricants and fluids used in automotive manufacturing, helping to prevent damage to machinery and ensure the quality of the final product. By incorporating 20 micron screens into their filtration systems, automotive manufacturers can improve the reliability and performance of their equipment, leading to increased productivity and cost savings.

The aerospace industry is yet another sector that has benefited from the use of 20 micron screens. In this industry, precision and reliability are critical to ensuring the safety of aircraft and spacecraft. 20 micron screens are able to provide the level of filtration needed to remove small particles and contaminants from fluids and gases used in aerospace applications, helping to maintain the integrity of critical systems and components. By using 20 micron screens in their filtration processes, aerospace companies can ensure the safety and reliability of their products, meeting the stringent requirements of the industry.

In conclusion, the 20 micron screen has proven to be a versatile and effective solution for fine particle filtration in a wide range of industries. From food and beverage to pharmaceuticals, automotive to aerospace, the 20 micron screen has demonstrated its ability to provide the level of filtration needed to ensure the quality, safety, and reliability of products and processes. By incorporating 20 micron screens into their filtration systems, companies can achieve greater efficiency, productivity, and cost savings, making them an essential tool for success in today’s competitive marketplace.