Table of Contents

Benefits of Using micron nylon mesh for filtration

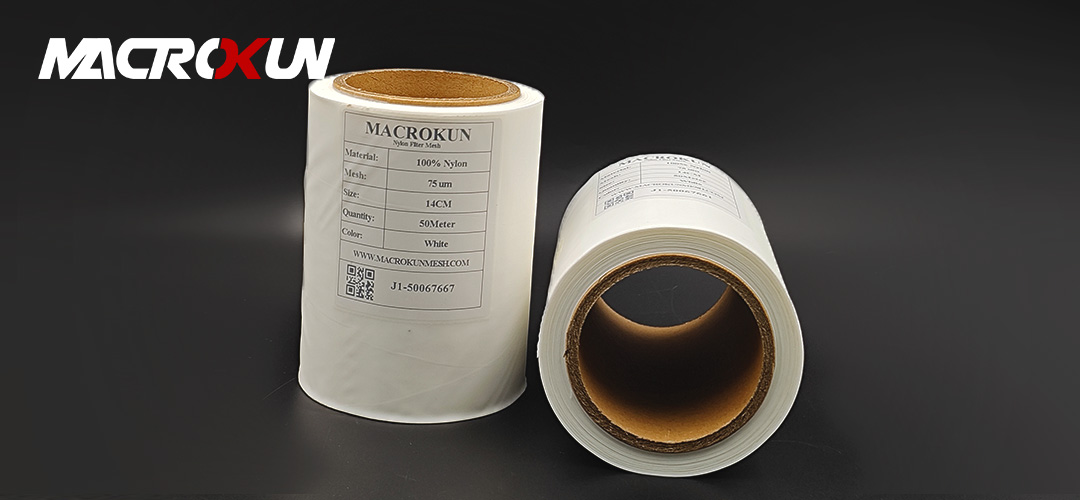

micron nylon mesh is an essential tool for industries that require clean and precise filtration. This type of mesh is made from high-quality nylon material that is woven into a fine mesh structure, allowing for the filtration of particles as small as one micron in size. The benefits of using micron nylon mesh for filtration are numerous and can greatly improve the efficiency and effectiveness of filtration processes.

One of the key benefits of using micron nylon mesh for filtration is its ability to provide a high level of filtration accuracy. The fine mesh structure of micron nylon mesh allows for the removal of even the smallest particles from a liquid or gas stream, ensuring that the end product is free from contaminants. This level of filtration accuracy is essential for industries such as pharmaceuticals, food and beverage, and electronics, where even the smallest impurities can have a significant impact on product quality.

In addition to its high level of filtration accuracy, micron nylon mesh is also highly durable and long-lasting. The nylon material used to make this type of mesh is resistant to chemicals, abrasion, and high temperatures, making it ideal for use in a wide range of industrial applications. This durability ensures that micron nylon mesh can withstand the rigors of continuous use without losing its effectiveness, providing a reliable and cost-effective filtration solution for businesses.

Another benefit of using micron nylon mesh for filtration is its versatility. This type of mesh can be customized to meet the specific filtration requirements of different industries, with options available for different mesh sizes, pore sizes, and thicknesses. This versatility allows businesses to tailor their filtration processes to their specific needs, ensuring that they can achieve the level of filtration accuracy required for their products.

Furthermore, micron nylon mesh is easy to clean and maintain, making it a convenient option for businesses looking to streamline their filtration processes. The smooth surface of nylon mesh allows for easy cleaning, while its durable construction ensures that it can withstand repeated cleaning without losing its effectiveness. This ease of maintenance helps businesses save time and money on filtration equipment, while also ensuring that their filtration processes remain efficient and reliable.

Overall, the benefits of using micron nylon mesh for filtration are clear. This type of mesh provides a high level of filtration accuracy, durability, versatility, and ease of maintenance, making it an essential tool for industries that require clean and precise filtration. By investing in micron nylon mesh, businesses can improve the efficiency and effectiveness of their filtration processes, leading to higher-quality products and increased customer satisfaction.

How to Choose the Right Micron Nylon Mesh for Your Filtration Needs

Micron nylon mesh is an essential tool for achieving clean and precise filtration in a variety of industries. Whether you are in the food and beverage industry, pharmaceuticals, or any other field that requires filtration, choosing the right micron nylon mesh is crucial for ensuring the quality and efficiency of your filtration process.

When it comes to selecting the right micron nylon mesh for your filtration needs, there are several factors to consider. The first and most important factor is the micron rating of the mesh. The micron rating refers to the size of the openings in the mesh, which determines the size of particles that can pass through. The lower the micron rating, the smaller the particles that can be filtered out. For example, a mesh with a micron rating of 100 will filter out larger particles than a mesh with a micron rating of 50.

Another important factor to consider when choosing micron nylon mesh is the material of the mesh itself. Nylon is a popular choice for filtration applications due to its durability, flexibility, and resistance to chemicals and abrasion. However, there are different types of nylon mesh available, each with its own unique properties. For example, monofilament nylon mesh is known for its high strength and precision, making it ideal for applications that require fine filtration. On the other hand, multifilament nylon mesh is more flexible and has a higher flow rate, making it suitable for applications that require a higher throughput.

In addition to micron rating and material, it is also important to consider the weave of the nylon mesh. The weave refers to the pattern in which the threads of the mesh are intertwined, which can affect the strength, flexibility, and filtration efficiency of the mesh. Common weave patterns for nylon mesh include plain weave, twill weave, and Dutch weave, each offering different levels of filtration and flow rate.

When choosing micron nylon mesh for your filtration needs, it is important to consider the specific requirements of your application. For example, if you are filtering out large particles, a mesh with a higher micron rating may be sufficient. However, if you require fine filtration for sensitive materials, a mesh with a lower micron rating and a tight weave may be necessary.

It is also important to consider the operating conditions of your filtration system when choosing micron nylon mesh. Factors such as temperature, pressure, and chemical compatibility can all affect the performance and lifespan of the mesh. Be sure to select a mesh that is designed to withstand the specific conditions of your application to ensure optimal filtration efficiency.

In conclusion, micron nylon mesh is an essential component of any filtration system, providing clean and precise filtration for a wide range of industries. When choosing the right micron nylon mesh for your filtration needs, consider factors such as micron rating, material, weave, and operating conditions to ensure the quality and efficiency of your filtration process. By selecting the right micron nylon mesh, you can achieve superior filtration results and maintain the integrity of your products.

Applications of Micron Nylon Mesh in Various Industries

Micron nylon mesh has emerged as a critical component in various industries, serving as an essential tool for clean and precise filtration. Its unique properties make it suitable for a wide range of applications, from pharmaceuticals to food processing, and even in the manufacturing of electronics. The versatility of micron nylon mesh lies in its ability to provide effective filtration while maintaining structural integrity under various conditions. This characteristic is particularly important in industries where contamination can lead to significant quality issues or safety concerns.

In the pharmaceutical industry, the need for stringent filtration processes cannot be overstated. Micron nylon mesh is utilized to filter out impurities and particulates from liquids and gases, ensuring that the final products meet the highest standards of purity. The mesh’s fine filtration capabilities allow for the removal of bacteria and other contaminants, which is crucial in the production of sterile products. Furthermore, the durability of nylon mesh ensures that it can withstand the rigorous cleaning processes required in pharmaceutical manufacturing, making it a reliable choice for companies committed to maintaining compliance with regulatory standards.

Similarly, in the food and beverage sector, micron nylon mesh plays a vital role in ensuring product safety and quality. It is commonly used in the filtration of liquids, such as juices, oils, and sauces, where it effectively removes unwanted particles that could affect taste or safety. The mesh’s ability to provide consistent filtration results helps manufacturers maintain product integrity and consumer trust. Additionally, the ease of cleaning and reusability of nylon mesh makes it a cost-effective solution for food processors looking to optimize their operations while adhering to health regulations.

The electronics industry also benefits from the use of micron nylon mesh, particularly in the production of components that require precise filtration. In this context, the mesh is often employed to filter out dust and other particulates during the manufacturing process, which can be detrimental to the performance of electronic devices. By ensuring a clean environment, manufacturers can enhance the reliability and longevity of their products. Moreover, the lightweight nature of nylon mesh allows for easy integration into various production systems, further streamlining the manufacturing process.

In addition to these industries, micron nylon mesh finds applications in water treatment and environmental management. Its ability to filter out fine particles makes it an effective tool for purifying water, whether in municipal systems or industrial applications. As concerns about water quality continue to grow, the demand for reliable filtration solutions has increased, positioning micron nylon mesh as a key player in efforts to provide clean and safe water. The mesh’s resistance to chemicals and UV light further enhances its suitability for outdoor and harsh environments, ensuring long-lasting performance.

Moreover, the textile industry has also recognized the advantages of micron nylon mesh, particularly in the production of specialized fabrics that require filtration properties. These fabrics are often used in applications such as protective clothing and industrial filters, where the need for durability and filtration efficiency is paramount. The adaptability of nylon mesh allows manufacturers to create products that meet specific performance criteria, thereby expanding its utility across various sectors.

In conclusion, the applications of micron nylon mesh in various industries underscore its importance as a filtration solution. Its effectiveness in removing contaminants, coupled with its durability and versatility, makes it an indispensable tool in maintaining product quality and safety. As industries continue to evolve and face new challenges, the role of micron nylon mesh in ensuring clean and precise filtration will undoubtedly remain significant, driving innovation and efficiency across multiple sectors.